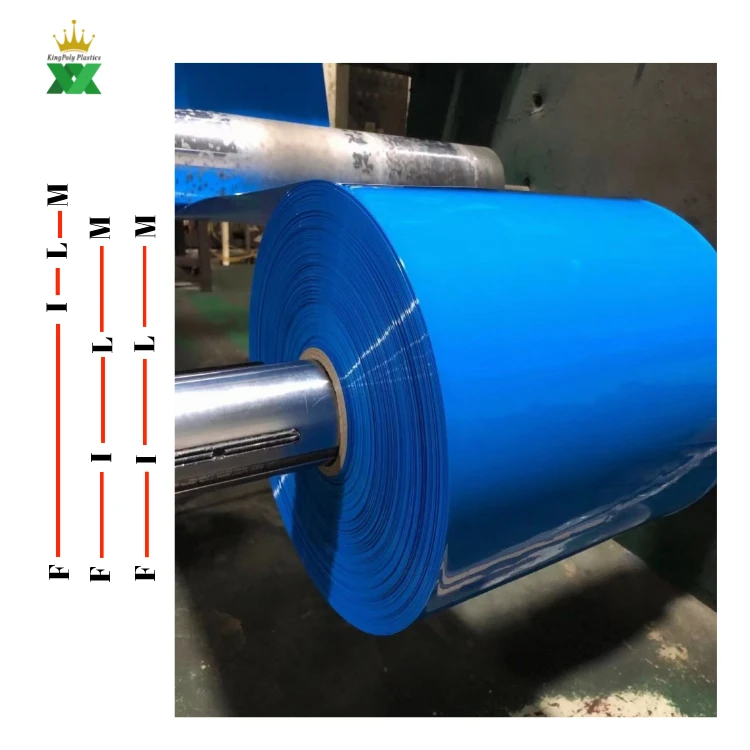

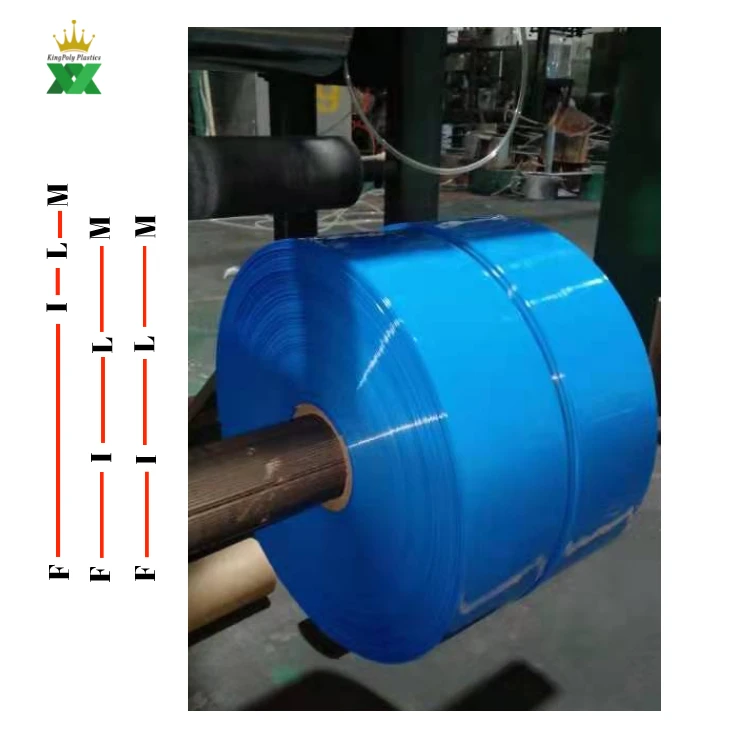

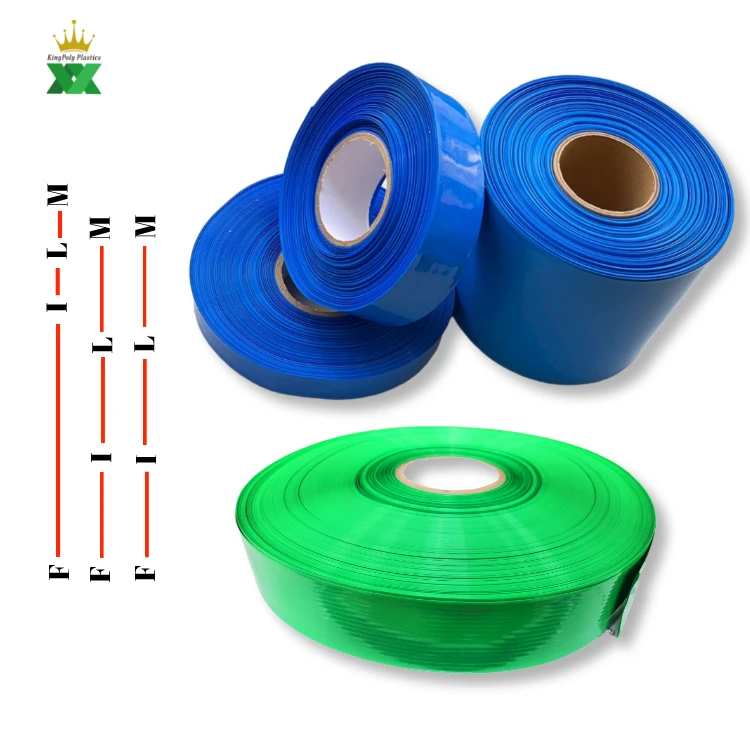

350mm wide lithium battery film wrap with PVC heat shrink tubes Blue

- Category: >>>

- Supplier: Foshan Shunbaoli Plastic Products Co. Ltd.Foshan Ltd.

Share on (1601203703775):

Product Overview

Description

Flat Width 9.85in(250mm) and Length 16.4ft PVC Heat Shrink Wrap Tube for 18650 21700 Lithium Battery DIY Battery Packs Blue

- Product name: PVC heat shrinkable tube

- Specifications: Flattening width 66mm (diameter about 42mm), wall thickness 0.1mm

- Shrinkage temperature: 80°C

- Temperature range: -40°C~105°C

- Temperature resistance class: 105°C

- Shrinkage rate: ≥48±5%

- Rated voltage: 300V

- Product packaging: 200 meters/rollProduct color: blue,black,Red,transparent,White,yellow,fruit green,green,silver gray,Purple

We have various sizes of width roll and cut the length according to client necessities We additionally have battery cells, plastic holders, nickel strip, handheld spot welder, Insulation Barley Paper,PVC, High-temperature Resistant Adhesive Tape, and so on We have the total answer for lithium-particle battery pack assembly.PVC Heat Shrink Sleeve for Lithium-particle Battery Pack for some, applications like battery-powered Led Bulb, Solar Street Light, Solar Led Light, Energy Storage System, POS Machine, Power Bank Device, and E-Vehicles (E-Cycle, E-Bike, E-bike, E-Rickshaw, and E-Cart, and so on) and significantly more application.

The Ultimate Guide to Battery Shrink Wrap Packaging: Protecting and Insulating Your Power Sources

What is Battery Shrink Wrap?

- Insulation

- Protection against physical damage

- Flame retardancy

- Color-coding and identification

- Improved aesthetics

Types of Battery Shrink Wrap Materials

PVC (Polyvinyl Chloride)

- Flexibility

- Durability

- Heat resistance

- Electrical insulation

- Available in various colors

Fiberglass

- High voltage insulation

- Extreme temperature resistance

- Fire-proof properties

Silicone-Coated Fiberglass

- Rubber-like texture

- Excellent fire resistance

- Suitable for high-temperature environments

Applications of Battery Shrink Wrap

- 18650 Lithium-ion batteries

- 21700 batteries

- 32650 batteries

- Custom battery packs

- Single cell protection

- Multi-cell battery pack insulation

- Terminal insulation

Key Features of Quality Battery Shrink Wrap

- Flame Retardancy: Ensures safety in case of battery malfunction

- Insulation Properties: Protects against electrical shorts

- Customizable Sizes: Available in widths from 17mm to 600mm

- Color Options: Includes transparent, blue, black, red, and multi-color options

- Pre-Cut Options: Convenient for single-cell applications

- Thickness Variations: Suitable for different protection levels

Benefits of Using Battery Shrink Wrap

- Enhanced Safety: Provides an extra layer of protection against short circuits and physical damage

- Improved Aesthetics: Creates a clean, professional look for battery packs

- Easy Identification: Color-coding helps in quick battery identification

- Moisture Resistance: Helps protect batteries from environmental factors

- Cost-Effective: Offers an affordable solution for battery protection

How to Apply Battery Shrink Wrap

- Measure and cut the shrink wrap to size (if not using pre-cut sleeves)

- Slide the wrap over the battery or battery pack

- Use a heat gun or hair dryer to carefully apply heat evenly

- The wrap will shrink and conform to the battery shape

- Allow to cool before handling

Choosing the Right Shrink Wrap for Your Needs

- Battery Type and Size: Ensure compatibility with your specific battery model

- Application Requirements: Consider factors like voltage, temperature, and environmental conditions

- Color Preferences: Choose based on aesthetic or identification needs

- Quantity: Determine whether individual pre-cut sleeves or larger rolls are more suitable

Popular Battery Shrink Wrap Products

- PVC Heat Shrink Tube for 18650 Battery Packing

- Blue PVC Heat Shrink Cable Sleeve

- Transparent Custom Color PVC Heat Shrink Tube

- High Voltage 2715 Fiberglass Insulation Sleeve

- Silicone Coated Flexible Fiberglass Fire Sleeve

Highlights:

Adaptability

mechanical and dielectric ability

Fire obstruction,

Low-temperature shrinkage and so on

Warming Facility:

Heat Gun

Consistent temperature broiler

Hairdryer

Transmission type heat charge Shrink machine and so on.

Conclusion

We Recommend

New Arrivals

New products from manufacturers at wholesale prices