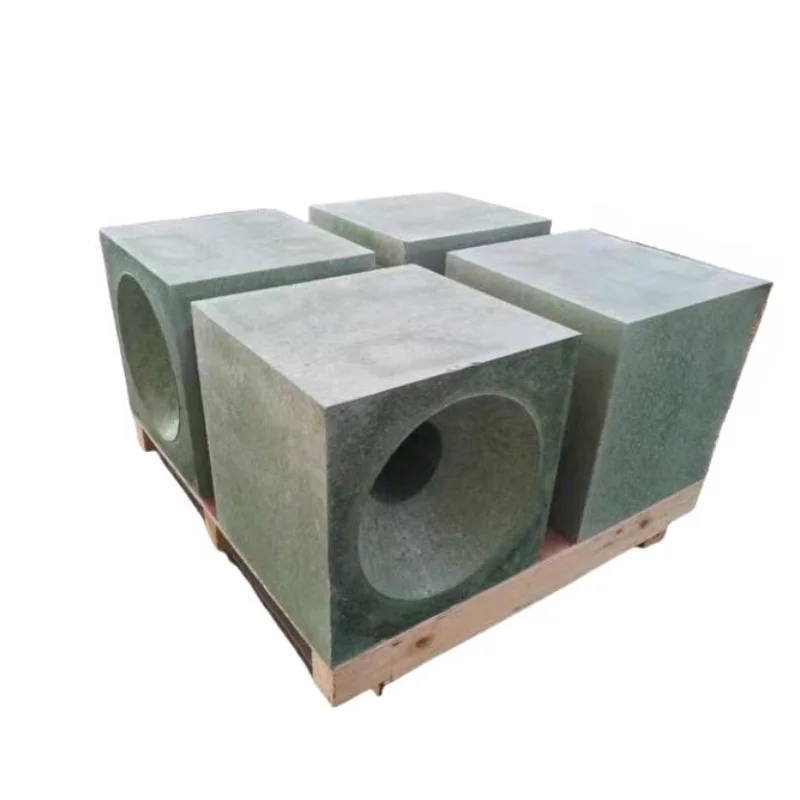

refractory erosion resistance Italian pouring machine parts casting water port

- Category: >>>

- Supplier: Gaomi Jiangsheng Metal Products Co. Ltd.

Share on (1601203894507):

Product Overview

Description

Product details

We follow our client’s blueprints to create different bottom pouring machine parts, Its temperature range is 1400-1700.This product has a lifespan of 2-10 days.For many years we’ve worked with the U.S,Germany,France,the UK ,Canada and other many countries.Our company has won many praises of others and gaining their business. Therefore

we’ve also built an extensive experience in exporting and quality assurance. It’s our hope to be able to work with you.

we’ve also built an extensive experience in exporting and quality assurance. It’s our hope to be able to work with you.

Products Description

Material | AL2O3,SiC |

Standard | as your request |

Color | Black,grey,etc |

Size | According to your requirements |

Surface Finish | oxidation coating |

Specification | We will provide various styles according to your requirements |

Test equipment | Salt spray endurance test, mechanical sizes test,certification according your need and etc |

Quality system | ISO standard, All products are strictly produced according to ISO standards |

Inspection process | Incoming Inspection → Quality Control →Final Quality Control → Quality control before shipment |

Product Instructions

Installation of plug rod water outlet

* The bottom of the plug rod into the clamp device, the two sides of the positioning pin is inserted into the plug rod pin hole and close, it is strictly prohibited to knock;* Turn the top fixed screw, pull the plug rod, so that the plug rod can not rotate and shake;

* Lift the clamping device vertically and rotate slowly to check whether the plug rod is installed vertically;

* If the plug rod is not vertical, it needs to be recalibrated

* The holding device is fixed to the equipment, which needs to cooperate vertically with the water mouth;

* Check the perpendicularity of the plug rod and the water outlet with the slag pass rod.

Precautions for plug rod

* Keep the product dry and no damp.* Be sure to take it lightly, no bump.

* The plug rod nozzle should be preheated before use, and baked with gas to more than 600℃.

* It is recommended to use the vertical switch in the early stage, and then rotate the lax phenomenon;

* The plug rod rotation shall not exceed 30°.

* The plug rod nozzle is best used continuously. If the secondary use needs to strengthen the baking, if the preheating is not in place, it may affect the service life.

Our Company

About our company

We as a company have an integrated production system in equipment production, we do both castings and mechanical processing.Our main equipment are two casting machines and physics and chemical testing equipment; all of these equipment for a fully functional production plant.

Production process and equipment

Packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services

will be provided.

will be provided.

FAQ

1. who are we?

We are based in Shandong, China, start from 2015,sell to North America(30.00%),South America(30.00%),Eastern

Europe(10.00%),Eastern Asia(10.00%),Western Europe(10.00%),Northern Europe(10.00%),Domestic Market(10.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

castings,Building castings,sand casting,Electric power fittings,Auto Parts

4. why should you buy from us not from other suppliers?

We have 20 years of production experience,Our products are for various uses in the following areas; such as building construction,

Power engineering accessories, highways and agricultural equipment. We follow our client's drawing to create differen par

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,Cash;

Language Spoken:English,Chinese

We are based in Shandong, China, start from 2015,sell to North America(30.00%),South America(30.00%),Eastern

Europe(10.00%),Eastern Asia(10.00%),Western Europe(10.00%),Northern Europe(10.00%),Domestic Market(10.00%). There are total about

11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

castings,Building castings,sand casting,Electric power fittings,Auto Parts

4. why should you buy from us not from other suppliers?

We have 20 years of production experience,Our products are for various uses in the following areas; such as building construction,

Power engineering accessories, highways and agricultural equipment. We follow our client's drawing to create differen par

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,Cash;

Language Spoken:English,Chinese

Contact us

Email:jiangshengmetal@163.com

WhatsApp:+8613589165836

We Recommend

New Arrivals

New products from manufacturers at wholesale prices