Best Selling CNC milling and drilling machine for Aluminum window and door

- Category: >>>

- Supplier: Shandong Zhengke Automation Co. Ltd.Shandong Ltd.

Share on (1601204418084):

Product Overview

Description

Products Description

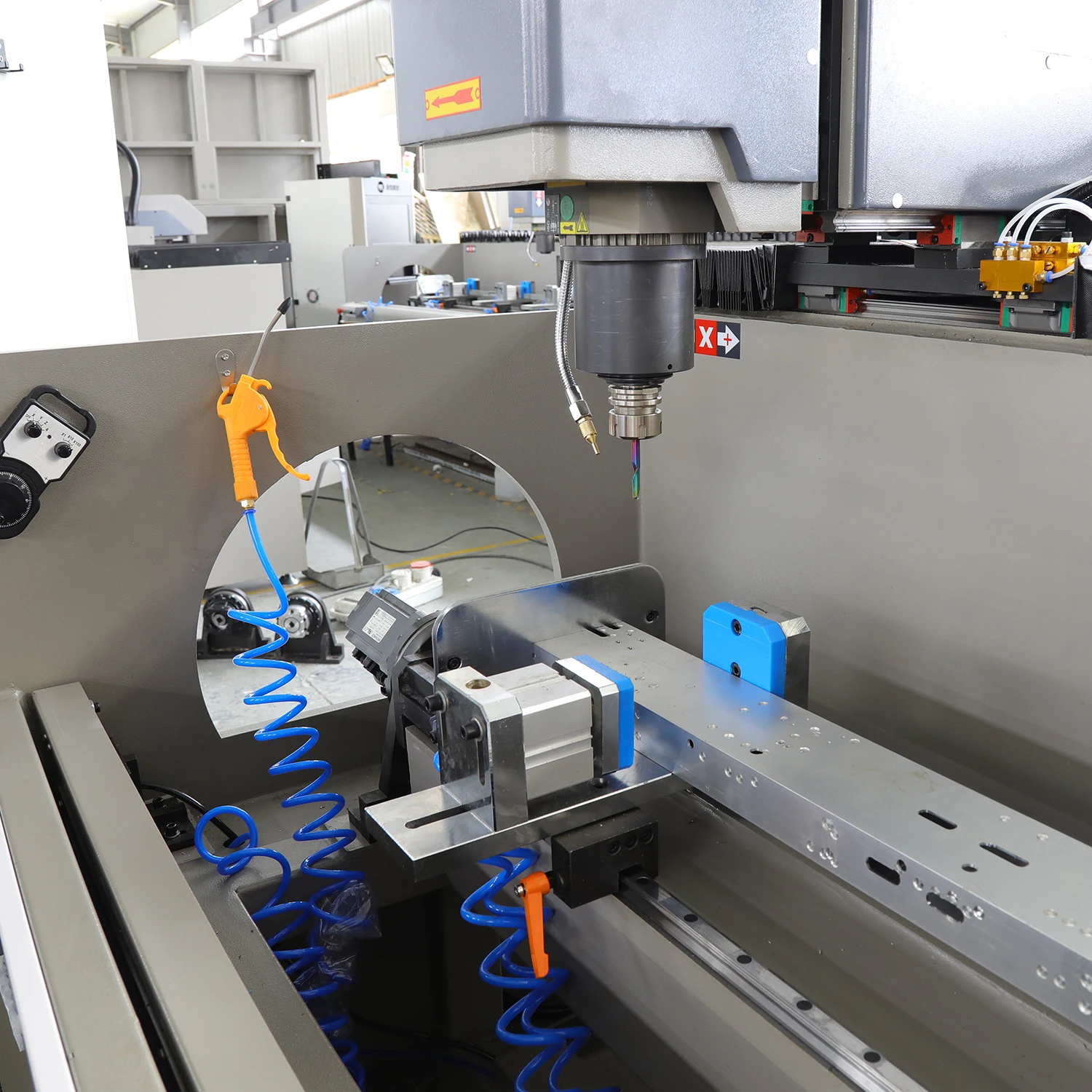

CNC MILLING AND DRILLING MACHINE

It is suitable for the processing of round holes, slot holes, key holes and special-shaped holes of industrial aluminum

profiles, window and door, and curtain wall profiles(Programming customization)

profiles, window and door, and curtain wall profiles(Programming customization)

Features

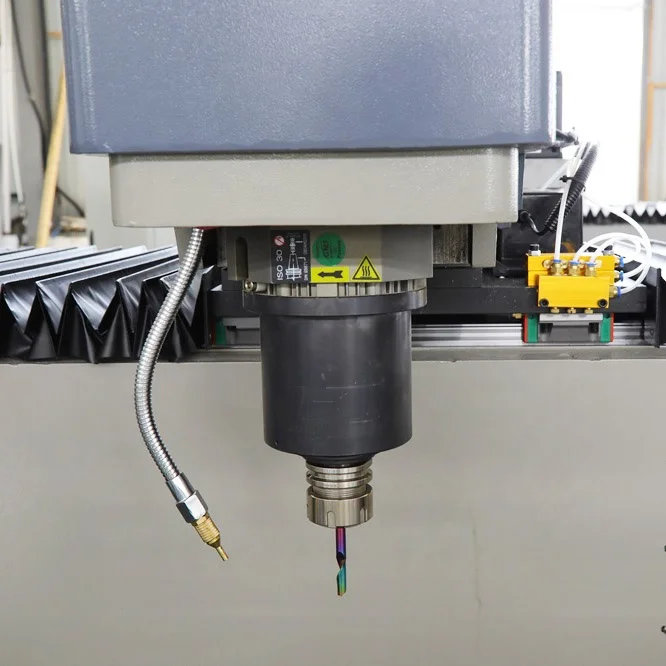

1. The spindle adopts an air-cooled electric spindle with a power of 9KW and a maximum speed of 24000 rpm, with high precision, good safety and high reliability.2. The German PA industrial CNC system is equipped with professional CAD-CAM programming software, with powerful functions, simple operation and high efficiency.

3. Can be equipped with 6 tool magazines, which can realize continuous and uninterrupted processing.

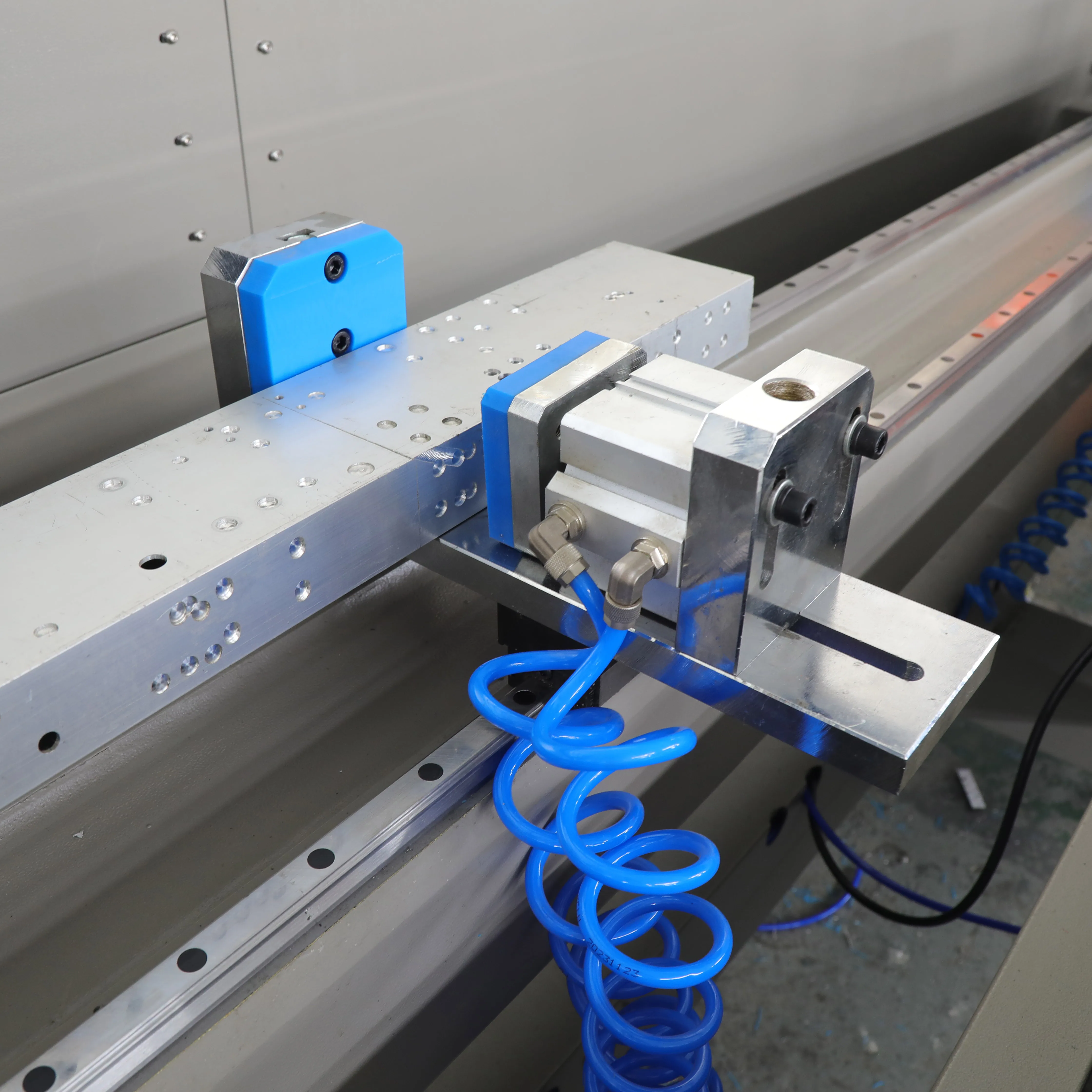

4. The worktable is turned 180°, -90°~0°~+90°, and the profile can be processed on three sides by one clamping. When processing deep through holes (special-shaped holes), deep hole processing can be realized by turning the worktable, which improves efficiency and good quality.

5. The automatic oil supply system is adopted, and the tool adopts a system-controlled spray cooling device.

6. The main components of the machine tool are made of steel, all of which have undergone vibration aging stress relief treatment to ensure stable operation of the machine tool.

Product Paramenters

WSZ-CNC-3200 (single head) | WSZ-CNC-1500 ( double head) | WSZ-CNC-1200 (single head) | WSZ-CNC-800 (single head) | |

Power Supply | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V-50Hz |

Input Power | 9kW | 9.5kW | 3.5kW | 3.5kW |

Rotating Speed | 18000rpm | 18000rpm | 18000rpm | 18000rpm |

Air Pressure | 0.5-0.8MPa | 0.5-0.8MPa | 0.5-0.8MPa | 0.5-0.8MPa |

X-axis Travel | 3200mm | 1500mm | 1200mm | 800mm |

Y-axis Travel | 400mm | 300mm | 300mm | 300mm |

Z-axis Travel | 300mm | 280mm | 280mm | 280mm |

Processing Range | 130x150mm | 110x150mm | 110x150mm | 110x150mm |

Overall Dimension | 4000x2000x2800mm | 2000x1800x2300mm | 1650x1500x2000mm | 1400x1500x2000mm |

Details Images

3-axis full-servo motors

Our three-axis full servo motor uses advanced control technology and high-precision encoders to achieve precise linkage of the three axes of X, Y, and Z. It can complete high-speed, high-precision motion tasks in a short time, greatly shortening the production cycle. . At the same time, its stable operating performance and low energy consumption ensure that your equipment continues to operate for a long time, bringing continuous power to your production line and greatly improving production efficiency.

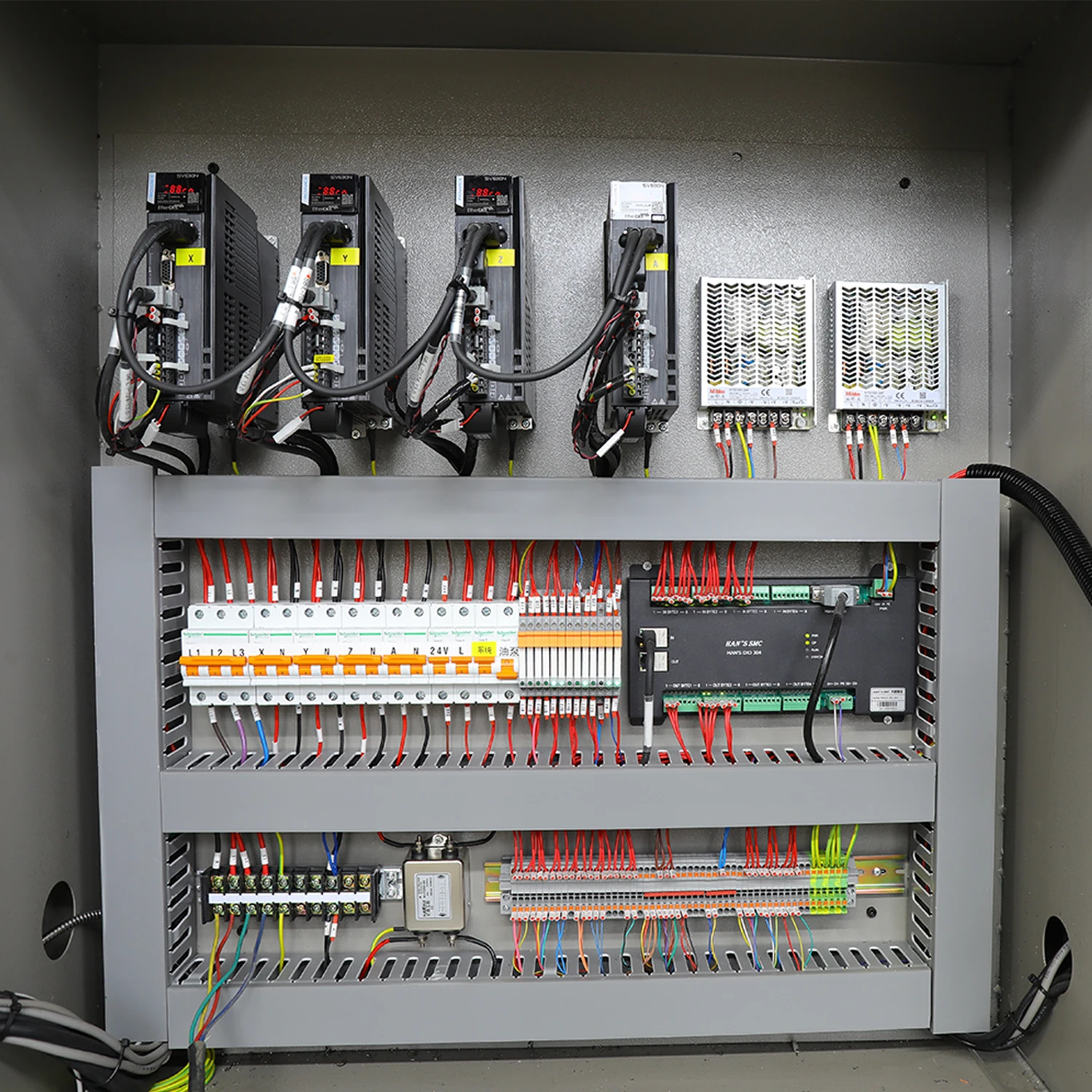

Brand of components

All of components are from international well-known brand, which can assure of the good quality and stability of running.

Item | Component | Model | Brand | Place of Origin |

1 | CNC system | HMDD-NH | Han's PA | Germany(Han's SMC) |

2 | Servo Motor | 0.75kW | INOVANCE | SHENZHEN,CHINA |

3 | Spindle | 9kW | CMT | GUANGDONG,CHINA |

4 | Electronic | ZB2-BE | Schneider | FRANCE |

5 | Guide Rail | 20.25 | HIWIN | TAIWAN |

6 | Lead Screw | CHTGH-020 | P&C | TAIWAN |

7 | Solenoid Valve | 4V210-08 | AIRTAC | TAIWAN |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

COMPANY PROFILE

Shandong Zhengke Automation Co., Ltd. was founded in 2014, located in Jiyang Industrial Park, Jinan, Shandong Province. The company covers an area of 5000 square meters, the core team of 50 people.Have independent technology design, research and development team. Have modern office space. Is the domestic professional glass

machinery high-tech enterprises.

The company focuses on window and door fabricating machinery and glass machinery, such as glass cutting machine.glass edging machine.glass washing machine.glass tempering machinery.insulating glassmachine.glass tempering machine.laminated glass machine...etc. The company has more than 1500 terminal customers, with good reputation, won the recognition of the majority of customers.

We have 2 independent technical patents, 12 Copyrights and 2 trademarks. The company developed a series of glass two-component glue machine advanced technology, sensitive reversing, continuous stability, high production efficiency, high degree of automation, easy to use; Widely used in two-component silicone structural adhesive, polysulfide adhesive, polyamine glue and other high accurate ratio, uniform mixing and fast operation occasions. Solve the phenomenon of high waste and low efficiency caused by manual work, is the ideal glass bonding production machine.

The company adheres to the business philosophy of "Honest and trustworthy, and prosper enterprises with science and technology", based on talent, technology, service and reputation, not only to provide customers with high quality glass machine, but also to provide you with case debugging machine, technical consulting guides, staff operation training and other comprehensive after-sales service.

machinery high-tech enterprises.

The company focuses on window and door fabricating machinery and glass machinery, such as glass cutting machine.glass edging machine.glass washing machine.glass tempering machinery.insulating glassmachine.glass tempering machine.laminated glass machine...etc. The company has more than 1500 terminal customers, with good reputation, won the recognition of the majority of customers.

We have 2 independent technical patents, 12 Copyrights and 2 trademarks. The company developed a series of glass two-component glue machine advanced technology, sensitive reversing, continuous stability, high production efficiency, high degree of automation, easy to use; Widely used in two-component silicone structural adhesive, polysulfide adhesive, polyamine glue and other high accurate ratio, uniform mixing and fast operation occasions. Solve the phenomenon of high waste and low efficiency caused by manual work, is the ideal glass bonding production machine.

The company adheres to the business philosophy of "Honest and trustworthy, and prosper enterprises with science and technology", based on talent, technology, service and reputation, not only to provide customers with high quality glass machine, but also to provide you with case debugging machine, technical consulting guides, staff operation training and other comprehensive after-sales service.

Exhibition

Certifications

Patent and Certification

In the future, we will continue to uphold the spirit of innovation, increase investment in R&D, continue to explore and make breakthroughs, contribute more to the development of the industry, and repay the support and love of our customers with better products and services!

FAQ

What is your core products?

Complete sets of aluminum and UPVC window and door fabricating machinery and glass machinery.

Where is your company located?

Our company is located in Jinan city, Shandong Province.

What is the delivery time?

For regular machine, we deliver within 15 working days and for customized machine, we deliver within 30 working days

Do you provide spare parts?

Yes, we do. We always keep amount of inventory of sparts parts all year round. We can send to customers at the first time.

Do you provide after-sale service abroad?

Yes, we do. We have professional after-sale team. They can go abroad to provide installation and commission service.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices