NUZHUO Nitrogen Generation Machine 99.999% High Purity N2 Producing Nice Price Nitrogen Plant Supply

- Category: >>>

- Supplier: Hangzhou Nuzhuo Technology Group Co. Ltd.

Share on (1601204520469):

Product Overview

Description

Product Description

Video Description

Product Name | PSA Nitrogen Gas Generator | ||||||

Model No. | NZN- 3/5/10/20/30/40/50/60/80/CUSTOMIZE | ||||||

Nitrogen Production | 3-3000Nm3/h | ||||||

Nitrogen Purity | 95~99.999% | ||||||

Nitrogen Pressure | 0.3~20Mpa(adjustable and customize) | ||||||

Dew Point | ≤-40 degree C | ||||||

Main Configuration

1. Air Compressor (Screw type): Air is used as raw material to collect & compress air to 8 bar.

2. Refrigerated Dryer: The standard configuration removes moisture and impurities in the air, so that the air dew point reaches -20°C (the intermediate configuration uses an adsorption dryer, and the dew point reaches -40°C; the advanced configuration uses a combined dryer, and the dew point reaches- 60ºC).

3. Precision Filter: A/T/C three-stage filter to remove oil, dust and impurities.

4. Air buffer Tank: store pure and dry air for subsequent adsorption and separation of oxygen as raw material storage.

5. Adsorption Tower: A&B adsorption tower can work alternately, regenerating adsorption, filling sodium molecular sieve to filter out oxygen molecules.

6. Oxygen Analyzer: real-time monitoring and analysis of oxygen purity, indicating that the equipment is working normally and alarming.

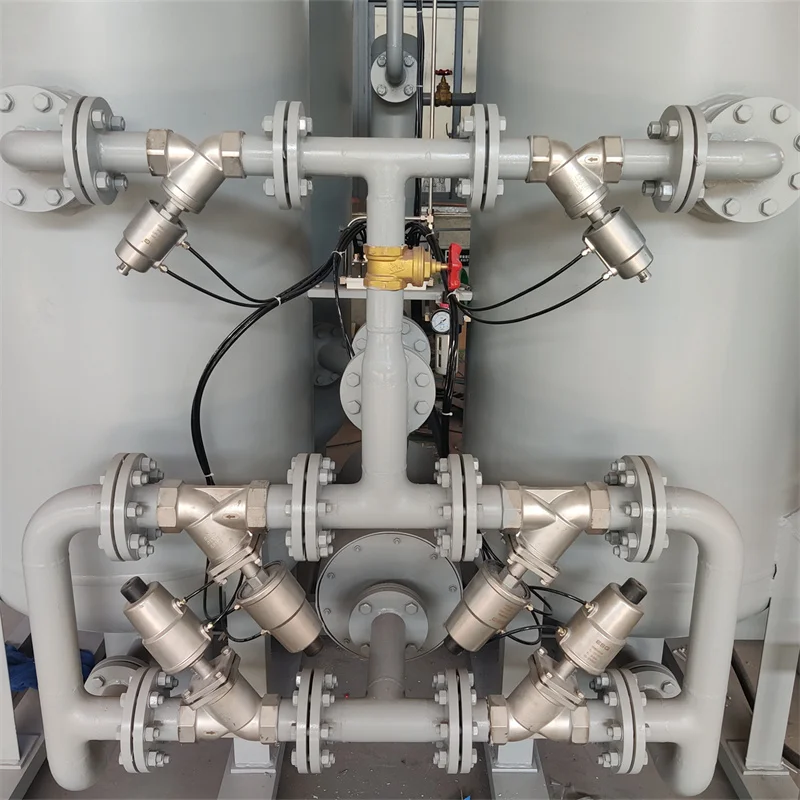

7. Valves & Pipelines: Intelligent control valves realize automatic operation of equipment, PLC control, SUS304 pipelines.

8. Oxygen Buffer Tank: Store oxygen with qualified purity, which can be directly piped or used for bottle filling.

9. Oxygen Booster: Gas booster, pressurize the oxygen to the filling pressure, generally 150bar or 200bar.

10. Filling Manifold: split high-pressure oxygen & nitrogen into each gas cylinder.

2. Refrigerated Dryer: The standard configuration removes moisture and impurities in the air, so that the air dew point reaches -20°C (the intermediate configuration uses an adsorption dryer, and the dew point reaches -40°C; the advanced configuration uses a combined dryer, and the dew point reaches- 60ºC).

3. Precision Filter: A/T/C three-stage filter to remove oil, dust and impurities.

4. Air buffer Tank: store pure and dry air for subsequent adsorption and separation of oxygen as raw material storage.

5. Adsorption Tower: A&B adsorption tower can work alternately, regenerating adsorption, filling sodium molecular sieve to filter out oxygen molecules.

6. Oxygen Analyzer: real-time monitoring and analysis of oxygen purity, indicating that the equipment is working normally and alarming.

7. Valves & Pipelines: Intelligent control valves realize automatic operation of equipment, PLC control, SUS304 pipelines.

8. Oxygen Buffer Tank: Store oxygen with qualified purity, which can be directly piped or used for bottle filling.

9. Oxygen Booster: Gas booster, pressurize the oxygen to the filling pressure, generally 150bar or 200bar.

10. Filling Manifold: split high-pressure oxygen & nitrogen into each gas cylinder.

Installation Solution

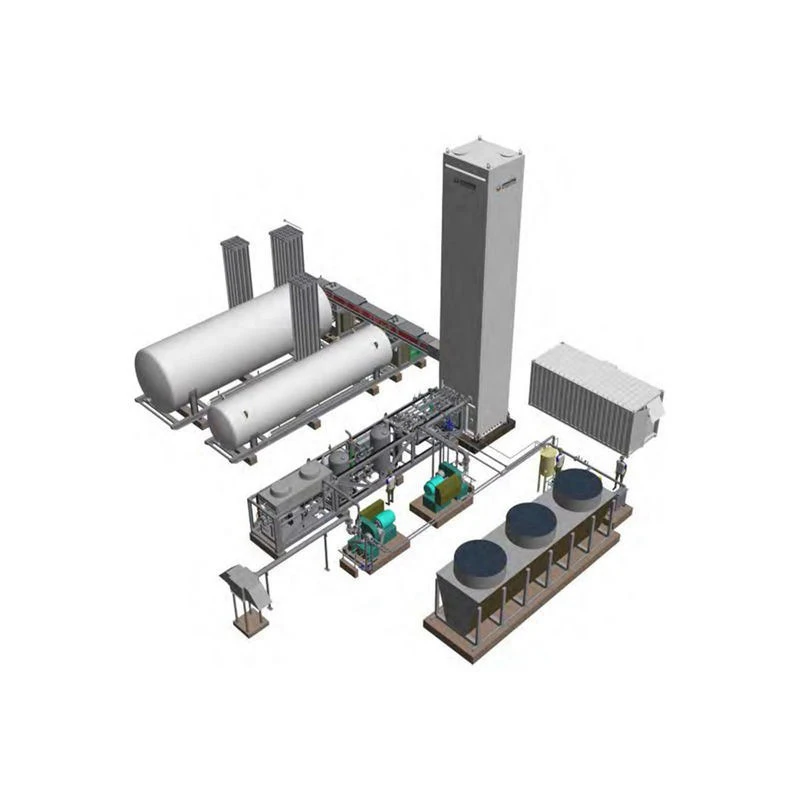

This nitrogen plant consists of screw type air compressor, nitrogen booster, air buffer tank, refrigerated dryer, filtration equipment, nitrogen buffer tank, nitrogen generator, nitrogen regulator, filling manifold,etc.

Step 1: Connecting A&B from the flange of the air compressor to the flange of the refrigerated dryer,using this black DN50 high pressure tube for connection.

Step 2: Connecting C&D from the nitrogen generator to the nitrogen booster, using this black DN50 high pressure tube for connection.

Step 3: Connecting F from the nitrogen booster to the filling manifold, using this black DN50 high pressure tube for connection.

Step 4: The filling manifold connect to nitrogen cylinders.

The following points should be noted during installation:

1. The connection between each equipment needs to be sealed!

2. Gaskets and screws need to be tightened!

3. Do not have air leakage phenomenon!

2. Gaskets and screws need to be tightened!

3. Do not have air leakage phenomenon!

Product Display

Salient features of PSA nitrogen generator plant :

1.Fully automated- systems are designed to work unattended.

2. PSA plants are compact taking little space, assembly on skids, prefabricated and supplied from factory.

3. Quick start-up time taking only 5 minutes to generate oxygen with desired purity.

4. Reliable for getting continuous and steady supply of oxygen.

3. Quick start-up time taking only 5 minutes to generate oxygen with desired purity.

4. Reliable for getting continuous and steady supply of oxygen.

5.Durable molecular sieves that last around 12 years.

Applications

We manufacture PSA nitrogen plant using the latest PSA (Pressure Swing Adsorption) technology. Being the leading PSA nitrogen plant manufacturer, it is our motto to deliver nitrogen machinery to our customers that is at par with international standards and yet is very competitively priced. We use premium quality materials bought from the best suppliers in the industry. Nitrogen generated in our PSA nitrogen generator meets the requirements of industrial as well as medical applications. Numerous companies from around the globe are using our PSA nitrogen plant and are generating nitrogen on-site for running their operations.

With our nitrogen generators, the industries and medical institutions are able to get uninterrupted supply of nitrogen. Our company uses cutting-edge technology in the making of the nitrogen machinery.

Recommend Products

Packing & Delivery

FAQ

Q1: Are you a trading company or manufacturer?

A: Firstly. we are a manufacturer, we have our own factory and engineers.

Secondly, we have our own international trade teams to provide services for you.

Thirdly, we provide the lifetime technology support and the best after-sale service.

Q2: What is your term of payment?

A: 30%T/T in advance and balance before shipment.

B. 30% T/T in advance and Irrevocable L/C at Sight.

C. Accept negotiation.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q3 How long is your delivery time?

A: Depending on what type of machine you are purchased.

PSA series, Gas compressor, the delivery time is 10-15 days.

Cryogenic ASU, the delivery time is at least 3 months.

Cryogenic liquid plant, the delivery time is at least 5 months.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

A: We offer a warranty period of 1 year, free lifetime technology support.

B. Supporting third-part to have a inspection, also provide SGS, TUV certificated.

C. Accept negotiation.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q5: Do you offer OEM/ODM service?

A: Yes.

Q6: Does your product used or new? RTS product or customized product?

A: Firstly. we are a manufacturer, we have our own factory and engineers.

Secondly, we have our own international trade teams to provide services for you.

Thirdly, we provide the lifetime technology support and the best after-sale service.

Q2: What is your term of payment?

A: 30%T/T in advance and balance before shipment.

B. 30% T/T in advance and Irrevocable L/C at Sight.

C. Accept negotiation.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q3 How long is your delivery time?

A: Depending on what type of machine you are purchased.

PSA series, Gas compressor, the delivery time is 10-15 days.

Cryogenic ASU, the delivery time is at least 3 months.

Cryogenic liquid plant, the delivery time is at least 5 months.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

A: We offer a warranty period of 1 year, free lifetime technology support.

B. Supporting third-part to have a inspection, also provide SGS, TUV certificated.

C. Accept negotiation.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q5: Do you offer OEM/ODM service?

A: Yes.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q6: Does your product used or new? RTS product or customized product?

A:Our machine is new unit, and following your specific require to design and make it.

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Why Choose NUZHUO

Contact Us

Contact: Riley.Zhang

Tel: +86-18758432320

Mail:Riley.Zhang@hznuzhuo.com

Whatsapp: +86-18758432320

WeChat: +86-18758432320

Web: www.hznuzhuo.com

Tel: +86-18758432320

Mail:Riley.Zhang@hznuzhuo.com

Whatsapp: +86-18758432320

WeChat: +86-18758432320

Web: www.hznuzhuo.com

www.nuzhuoasu.com

Facebook: www.facebook.com/NUZHUO

Facebook: www.facebook.com/NUZHUO

We Recommend

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

$170,000.00-180,000.00

New Arrivals

New products from manufacturers at wholesale prices