Factory Supply Y3150 Y3180 Small Cnc Gear Hobbing Machine Metal Gear Hobbing Machine For Sale Gear Processing Equipment

- Category: >>>

- Supplier: Henan Wadley Cnc Machinery Co. Ltd.

Share on (1601206075756):

Product Overview

Description

Product Description

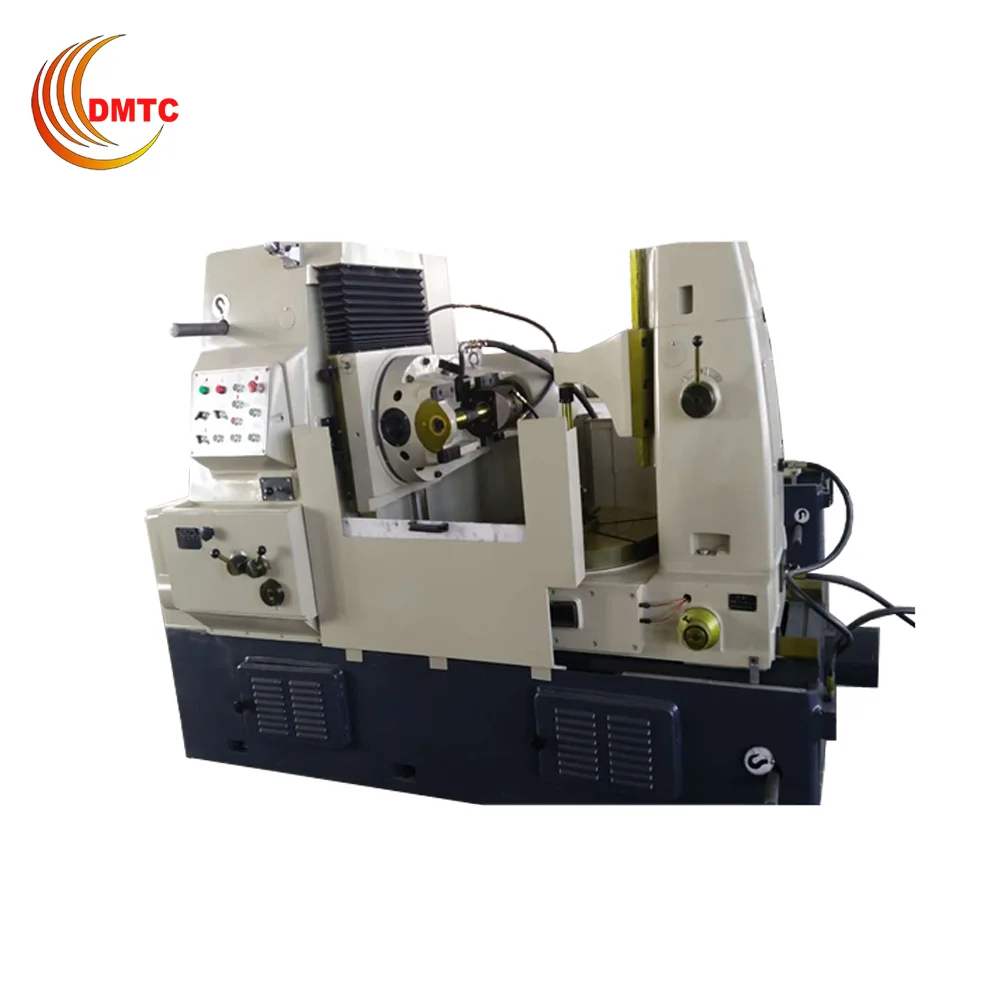

Universal Gear Hobbing Machine Y3150 Metal Processing Equipment

Gear hobbing machine is the most widely used type of gear processing machine tool. It can cut straight and helical cylindrical gears, as well as process worm gears, sprockets, etc. A gear processing machine tool for machining straight, helical, and herringbone cylindrical gears, as well as worm gears, using a hob according to the generative method. This machine tool can also process various special tooth shaped workpieces such as splines and sprockets when using specially designed hobs. The machining accuracy of ordinary gear hobbing machines is 7-6 levels (JB179-83), while high-precision gear hobbing machines are 4-3 levels. The maximum machining diameter is 15 meters.

2, The machine is characterized by good rigidity, high working accuracy, easy in operation and maintain.

3, The machine can be operated not only with forward and backward cutting, but also with axial or radial feed.

3, The machine can be operated not only with forward and backward cutting, but also with axial or radial feed.

4, The machine is suitable for large and single production of cylindrical spur and helical gears, worm gears and sprocket.

5, According to the special needs of users, can be raised or extended tool to expand the scope of the processing machine accuracy.

5, According to the special needs of users, can be raised or extended tool to expand the scope of the processing machine accuracy.

Product Paramenters

Model | Y3150 | YK3150 | Y3180 | YK3180 |

Max.workpiece dia.(mm) | 350/500 | 350/500 | 550/800 | 550/800 |

Control mode | Mechanical | KND/GSK | Hydraulic | KND/GSK |

Max.module(mm) | 5/6 | 5/6 | 8/10 | 8/10 |

Max Processing Width(mm) | 250 | 250 | 300 | 300 |

Hob diameter(mm) | 160 | 160 | 180 | 180 |

Hob abor diameters(mm) | Φ22,Φ27,Φ32 | Φ22,Φ27,Φ32 | Φ22,Φ27,Φ32,Φ40 | Φ22,Φ27,Φ32,Φ40 |

Max.hob dia.Xlength(mm) | 160*160 | 160*160 | 160*160 | 180*180 |

Worktable diameter(mm) | 520 | 520 | 650 | 650 |

Main motor power(kw) | 4 | 4 | 5.5 | 5.5 |

N.W./G.W.(kg) | 2500 | 2700 | 5500 | 5700 |

Four types available

Details Display

Y3150 Gear Hobbing Machine High Quality Hobbing Machine Made in China

(1)The machine tool is suitable for the batch, small batch and individual production of cylindrical gear and worm gear, suitable for roll cutting spline shaft in a certain range of parameters.

(2)The machine tool feartures good rigidness and extremely smal thermal deformation, enabling high-speed cutting and load cutting, with a very high prodution efficiency.

(3)The machine tool is convenient for adjustment, with auto stop mechanism, as well as reliable safe mechanism and auto lubrication system.

(2)The machine tool feartures good rigidness and extremely smal thermal deformation, enabling high-speed cutting and load cutting, with a very high prodution efficiency.

(3)The machine tool is convenient for adjustment, with auto stop mechanism, as well as reliable safe mechanism and auto lubrication system.

Control box.

(1) One click operation, fast and practical, without strict operation skills.

(2) The design is simple, safe and practical, and the voltage can be customized.

(3) Mechanical control and intelligent control

Rotary table.

(1) High frequency quenching table.

(2) High hardness, no deformation, solid and durable.

(3) When rotating, you can observe the gear processing progress at any time.

Hob shaft.

(1) High hardness and low loss at normal and high temperature.

(2) With high strength and toughness, the processing effect is remarkable.

(3) High wear resistance, good thermal conductivity and heat resistance.

Hob cutter.

(1) It can be divided into gear hobs, worm gear hobs, fixed hobs, etc. according to its use

(2) Rotate at a fixed speed ratio and cut the tooth profile of each adjacent position in turn.

(3) The special hob can process various special tooth shaped workpieces such as splines and sprockets

Effect Display

Product Application:

Gear hobbing machines are widely used in various mechanical manufacturing industries such as automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instruments, aircraft and spacecraft.A gear processing machine tool for processing various cylindrical gears, bevel gears, and other toothed parts. There are various types and specifications of gear processing machine tools, including small machine tools for processing gears with a diameter of several millimeters, large machine tools for processing gears with a diameter of more than ten meters, and high-precision machine tools for processing precision gears with efficient machine tools for mass production

Machine accessories

We will provide all kinds of spare parts and product instructions required by the gear hobbing machine for your safe use.

hobbing cutter(option)

Hob usage scene

Accessories and packaging

Company Profile

Henan Wadley CNC Machinery Co., Ltd. Located in Zhengzhou.the central place of China. With long time exporting machines experience, we can not only supplying our customers stable quality products ,but also more excellent service.we supply all kinds of Machine tool to international market, like Lathe machine, CNC Lathe Machine, Milling Machine, Drilling Milling Machine, Grinding Machine, Hydraulic Press, Bending Machine, Press brake, Shearing Machine, and Machine tool accessories. We have our own engineer who has more than years of working experience and is professionally trained. Our trained engineers can help customers on behalf of company not only inspect goods before shipping but also track all links of production process.

Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to buy.

Serving customers and satisfying customers is our purpose. We welcome every friend to visit our company. At the same time, we hope that we can not only be business partners, but also become good friends.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices