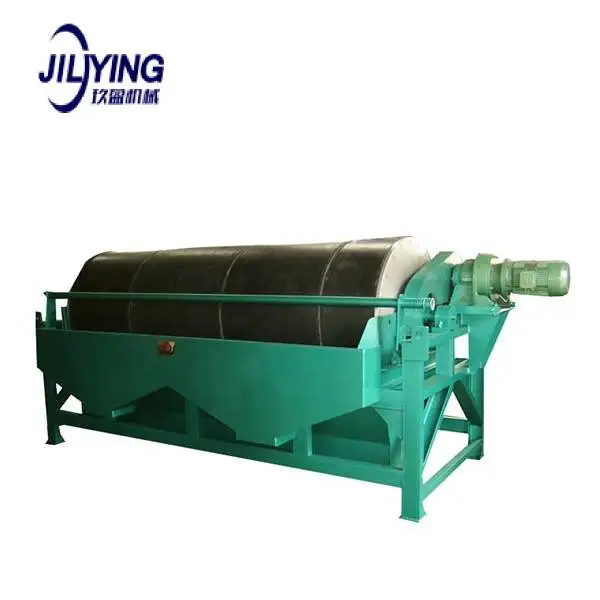

Wet drum mineral separator energy saving magnetic separator equipment recycling machine

- Category: >>>

- Supplier: Dalian J&Y Heavy Machine Co. Ltd.Dalian Ltd.

Share on (1601206580670):

Product Overview

Description

Contacts: Belinda sun

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: belinda @weldcnc.com

Mob/Whatsapp: +86 155 4231 8526

Fax: +86-411-39015062

Email: belinda @weldcnc.com

Mob/Whatsapp: +86 155 4231 8526

Product Description

What Is a Wet Drum Magnetic Separator?

The Wet Drum Magnetic Separator is a type of separator that is primarily used to extract extremely tiny magnetic components from low concentration, low-viscosity liquids. The wet drum separator is intended to use in the metal processing sector, as well as for the treatment of pre-concentrates obtained from the high gradient magnetic filter. In a wet drum separator, approximately 90% of the grain sizes ranging from 1 micron to 1000 micron may be separated as sludge.

Wet Drum Magnetic Separators: Why Use One?

The primary use of wet Magnetic drum separators is that it helps separate the non-magnetic material by using a magnetic separator. Its effectiveness in treating process streams contains a high percentage of magnetics and can produce a “clean” magnetic or non-magnetic product. They are made to provide ultimate protection to crushers, grinders, pulverizers, and allied equipment and are useful for the mining and ore industry.

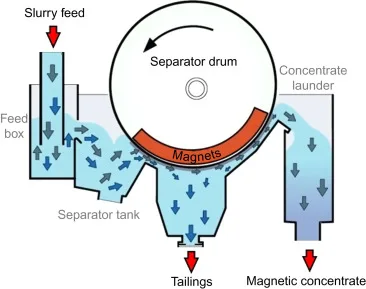

Wet Drum Magnetic Separator: Working Principle

When ferrous material is put to the drum surface, a magnetic field is created, which draws the ferrous material to the outer drum which is revolving. Because of this action, a self-cleaning action is created by continuously conveying the captured ferrous material out of the product flow to the ferrous discharge region.

* Grain sizes between 0.1mm-6mm

* Used in the processing of magnetite or ferrosilicon (FeSi) from sink/float separation and wet processing of fine grains

* Used in the processing of magnetite or ferrosilicon (FeSi) from sink/float separation and wet processing of fine grains

Structure :

The wet drum magnetic separator consists of a rotating magnetic drum disposed in a tank for receiving a flow slurry of a mixture of magnetic and non-magnetic particles . Slurry is fed to the tank and subsequently flows through the magnetic field generated by the drum. The ferromagnetics are attracted to the drum shell by the magnetic circuit and are rotated out of the slurry stream. The ferromagnetics discharge from the drum shell when rotated out of the magnetic field.

Features:

Wet drum magnets offer good magnetic recovery.

The feed slurries recover the magnetic field.

It comes in single or multiple drum versions.

Clean magnetic solids concentration.

Helps eliminate coil burn-outs.

On a mild steel shaft are magnet/pole parts.

The drum is composed of durable stainless steel.

Wet drum separators come in single, double, and multiple drum formats.

The feed slurries recover the magnetic field.

It comes in single or multiple drum versions.

Clean magnetic solids concentration.

Helps eliminate coil burn-outs.

On a mild steel shaft are magnet/pole parts.

The drum is composed of durable stainless steel.

Wet drum separators come in single, double, and multiple drum formats.

Product parameter

Model | Specification of magnetic drum | Rotation speed(rpm) | Handling Capacity | Motor Power | ||||

Diameter(mm) | Length(mm) | t/h | m3/h | kw | ||||

CTB/N/S44 | 400 | 400 | 45 | 1~2 | 3 | 1.1 | ||

CTB/N/S46 | 400 | 600 | 45 | 1~3 | 5 | 1.1 | ||

CTB/N/S63 | 600 | 300 | 40 | 3~5 | 8 | 1.1 | ||

CTB/N/S66 | 600 | 600 | 40 | 5~10 | 16 | 1.1 | ||

CTB/N/S69 | 600 | 900 | 40 | 8~15 | 24 | 1.1 | ||

CTB/N/S618 | 600 | 1800 | 40 | 15~30 | 48 | 2.2 | ||

CTB/N/S712 | 750 | 1200 | 35 | 15~30 | 48 | 3.0 | ||

CTB/N/S912 | 900 | 1200 | 28 | 18~30 | 45 | 4.0 | ||

Project Example

Our order and visitors

Since its establishment, Dalian J&Y Machinery Co., Ltd. has been adhering to the enterprise spirit of "pursuing excellence and exceeding expectations", insisting on improving user satisfaction and its own service level, receiving customers with high-level and convenient services, and devoting This kind of demand has won unanimous praise from customers.

Company Profile

Company Information

Dalian J&Y Machinery Equipment Co., Ltd. was established in 2012.We are an enterprise specializing in the development and sales of CNC machine tools and automatic welding equipment. We mainly sell Production lines, casting equipment, sheet metal processing equipment, welding equipment and so on.

Dalian J&Y Machinery Equipment Co., Ltd. covers an area of 66,600 square meters with a total investment of more than 150 million yuan. There are more than 120 employees, including 30 professional and technical personnel and 10 personnel with intermediate and senior titles. The company has excellent equipment, strong technical force, advanced manufacturing technology,complete testing methods and perfect quality system. There are more than 150 main equipment, 5 automated and semi-automated production lines, with an annual production capacity of 50,000 sets.

We adhere to the principle of "customers are the first priority" and continue to pursue innovation and development. We also strive to develop high-tech products to meet the needs of customers in different industries. Our goal is to become the most competitive enterprise in the field of providing automation products and cutting and welding equipment industry services. In short, join us and create a better future together, because J&Y can become your most reliable business partner!

Dalian J&Y Machinery Equipment Co., Ltd. covers an area of 66,600 square meters with a total investment of more than 150 million yuan. There are more than 120 employees, including 30 professional and technical personnel and 10 personnel with intermediate and senior titles. The company has excellent equipment, strong technical force, advanced manufacturing technology,complete testing methods and perfect quality system. There are more than 150 main equipment, 5 automated and semi-automated production lines, with an annual production capacity of 50,000 sets.

We adhere to the principle of "customers are the first priority" and continue to pursue innovation and development. We also strive to develop high-tech products to meet the needs of customers in different industries. Our goal is to become the most competitive enterprise in the field of providing automation products and cutting and welding equipment industry services. In short, join us and create a better future together, because J&Y can become your most reliable business partner!

Packing & Delivery

FAQ

Q1.What is our main product ?

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo

We Recommend

New Arrivals

New products from manufacturers at wholesale prices