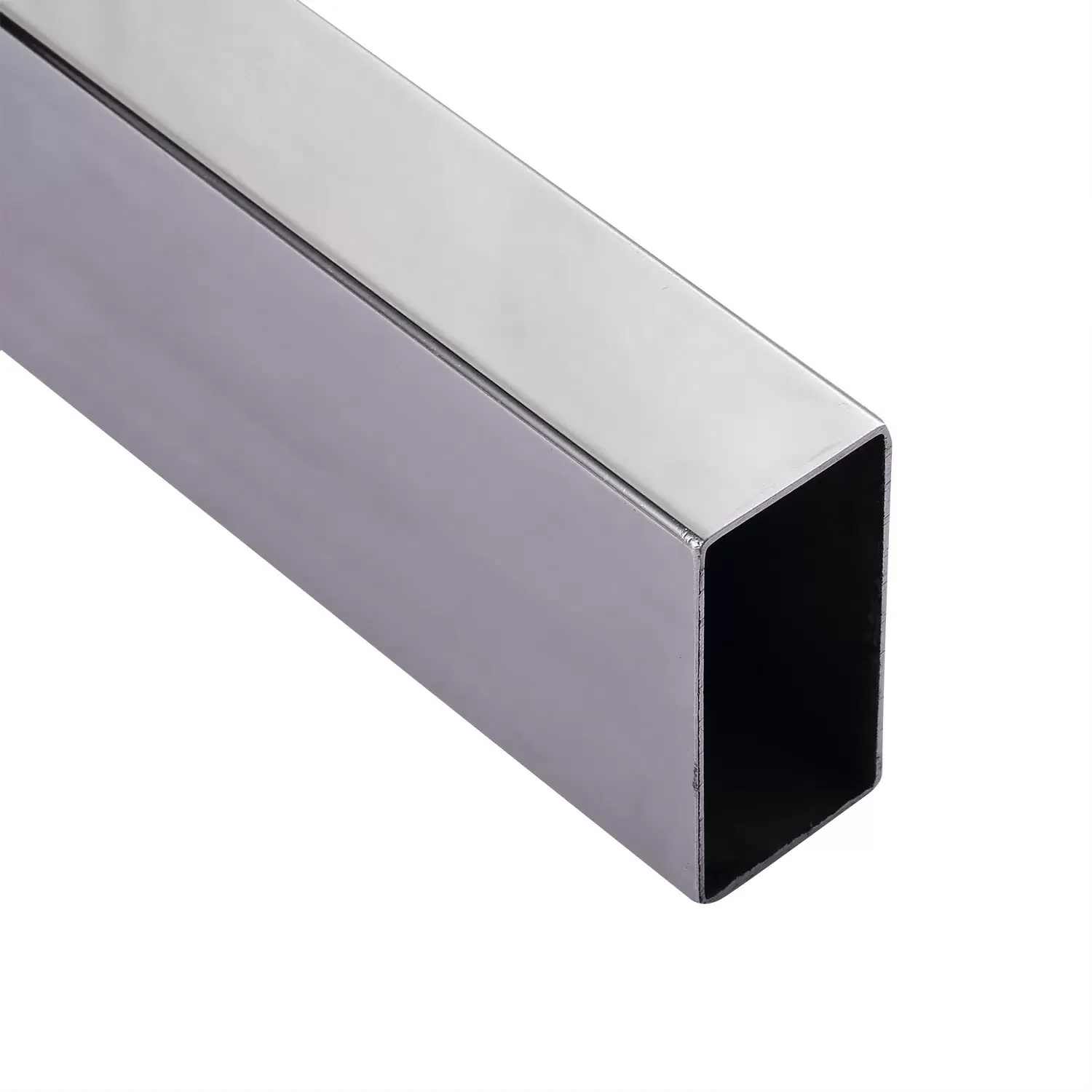

Hollow Section Pipe / Stainless Steel Square Tube from China

- Category: >>>

- Supplier: Tianjin Baolaili Galvanized Steel Pipe Co. Ltd.

Share on (1601207181413):

Product Overview

Description

PRODUCTS DESCRIPTION

| 304 Stainless Steel | 316 Stainless Steel | |

| Description | Grade 304 stainless steel is generally regarded as the most common austenitic stainless steel. It contains high nickel content that is typically between 8 and 10.5 percent by weight and a high amount of chromium at approximately 18 to 20 percent by weight. Other major alloying elements include manganese, silicon, and carbon. The remainder of the chemical composition is primarily iron. | Similar to 304, Grade 316 stainless steel has high amounts of chromium and nickel. 316 also contains silicon, manganese, and carbon, with the majority of the composition being iron. A major difference between 304 and 316 stainless steel is the chemical composition, with 316 containing a significant amount of molybdenum; typically 2 to 3 percent by weight vs only trace amounts found in 304. The higher molybdenum content results in grade 316 possessing increased corrosion resistance. |

| Application | 1.The application requires excellent formability. The higher molybdenum content in Grade 316 can have adverse effects on formability. | 1.The environment includes a high amount of corrosive elements. |

| 2.The application has cost concerns. Grade 304 is typically more affordable than Grade 316. | 2.The material will be placed underwater or be exposed to water consistently. | |

| 3.In applications where greater strength and hardness are required. | ||

| We choose austenitic stainless steels from BAOSTEEL or TISCO as raw materials. Because these raw materials have high-quality properties, the effects after surface treatment will be more diversified. Pickling, polishing, mirror polishing, satin brushing, powder coating, you can choose the effect you want according to actual needs, we will try our best to help you complete. | ||

CHEMICAL COMPOSITION & MECHANICAL PROPERTY

| Chemical Composition: | ASTM Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| ASTM 201 | ≤0.15 | ≤1.00 | 5.50~7.50 | ≤0.060 | ≤0.03 | 1.00 ~1.50 | 13.50~15.00 | \\ | |

| ASTM 202 | ≤0.15 | ≤1.00 | 7.50~10.00 | ≤0.060 | ≤0.03 | 4.00~6.00 | 17.00~19.00 | \\ | |

| ASTM 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~11.00 | 18.00~20.00 | \\ | |

| ASTM 304L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~13.00 | 18.00~20.00 | \\ | |

| ASTM 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | |

| ASTM 316L | ≤0.035 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | |

| ASTM 316L Ti | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | |

| ASTM 409L | ≤0.03 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.03 | \\ | 10.50~11.75 | \\ | |

| ASTM 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 | |

| Mechanical Property: | Grade of Material | Elongation (%) | Tensile Strengh (Rm) N/m m³ | Yield Strength (Rp) 0.2%N/m m³ | Hardness (HV) | ||||

| ASTM 201 | ≥35 | ≥520 | ≥210 | ≤253 | |||||

| ASTM 202 | ≥35 | ≥590 | ≥210 | ≤218 | |||||

| ASTM 304 | ≥35 | ≥520 | ≥210 | ≤200 | |||||

| ASTM 304L | ≥35 | ≥480 | ≥180 | ≤200 | |||||

| ASTM 316 | ≥35 | ≥520 | ≥210 | ≤200 | |||||

| ASTM 316L | ≥35 | ≥480 | ≥180 | ≤200 | |||||

| ASTM 316Ti | ≥40 | ≥520 | ≥205 | ≤200 | |||||

| ASTM 409L | ≥25 | ≥360 | ≥175 | ≤175 | |||||

| ASTM 904L | ≥35 | ≥490 | ≥216 | \\ | |||||

SIZE CHART

TEST AND INSPECTION

| Establishment | Steel Pipe production Line | Annual export sales volume | Certifications |

| Since 1991 | 8 | 200,000 tons | API 5L,API 5CT, UL852,FM ASTM A795,JIS G3444,JIS G3452, TUV,ISO, etc. |

| Employees | GI Production line | National accredited laboratory | Quality assurance |

| 1300 | 5 | 1 | Top 500 manufacturing enterprise in China |

PACKING

We Recommend

New Arrivals

New products from manufacturers at wholesale prices