Fully Automatic Mango Flavored Soft Candy Juice Content Gummy Machine and Production Line

- Category: >>>

- Supplier: Shanghai Target Industry Co. Ltd.Shanghai Ltd.

Share on (1601207185955):

Product Overview

Description

Product Description

Brief Introduction to GD80Q:

This line was specially innovated by our R&D department according to the market, which can produce gummy with multiple shapes and variety colors based on the advanced technology process. It is an ideal machine to produce superior quality gummy candy with single color, double color or filled centre. By change-over molds or depositors, different color and different shape of gummy can be also produced. The on-line mixer achieves the quantitative dosing and mixing of the flavor, color and acid. High degree of automation can produce high-quality gummy. At the same time it saves the manpower and the space occupation. This gummy machine production line mainly consists of cooking system, CFA system, depositing and cooling system.

Capacity | 50~80kg/h | Working Condition | 20~25℃, humidity 55% |

Voltage | Customized | Total Length | ~10m |

Total Power | About 84kw (electric heating) | Depositing Speed | 25~55n/min |

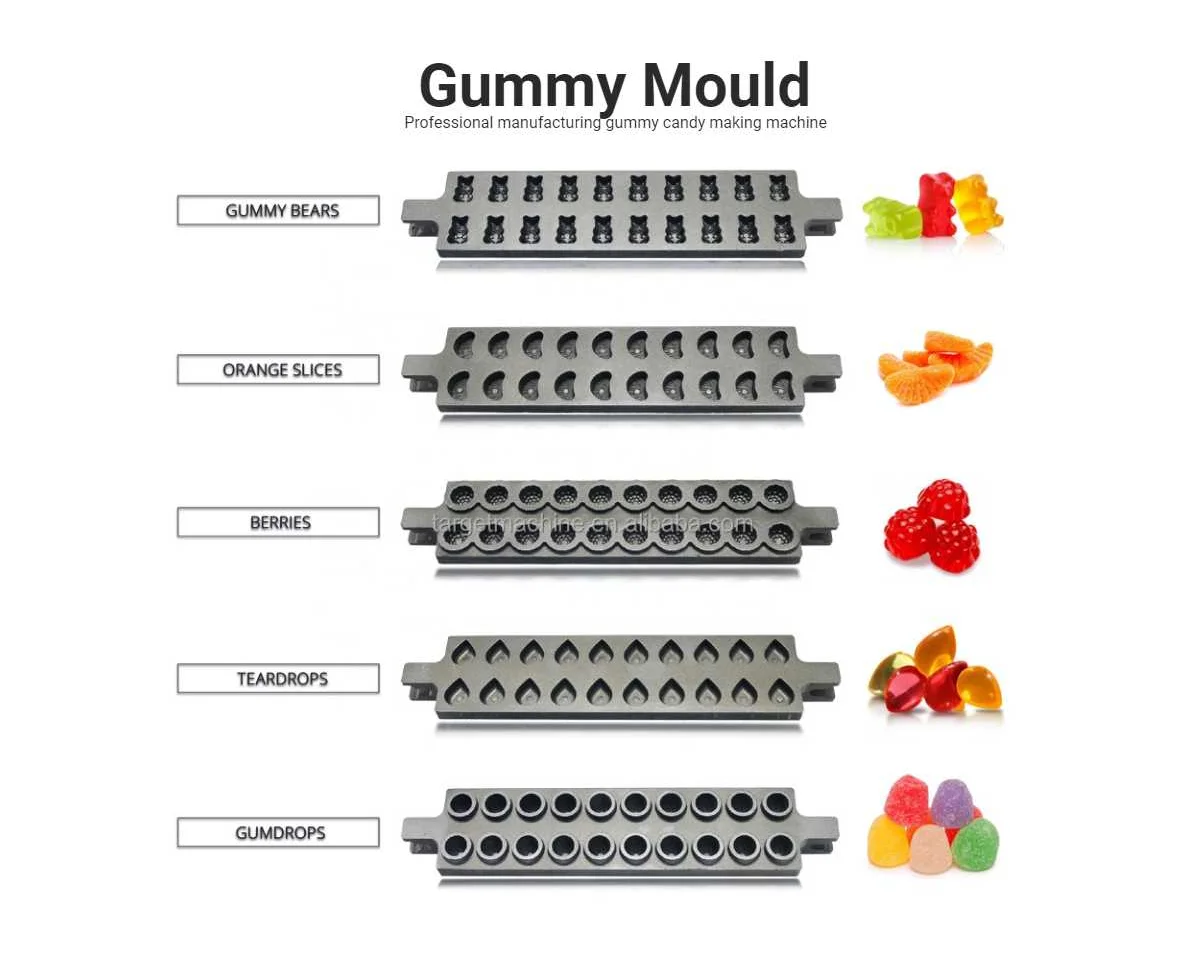

Candy Shape | Customized | Molds | 160pcs |

Cooking system is consists of jacket cooker, cooling tank and storage tank.

Materials: SUS304/316

Motor: WEG/ABB/Siemens

Transportation pump: Durrex lobe pump

Temperature control: Omron

Motor: WEG/ABB/Siemens

Transportation pump: Durrex lobe pump

Temperature control: Omron

effectively mix flavor color and other ingredients.The an oil-spraying machine makes the candy easier to demold.

The cooling system is used to cool the temperature of the candy.Stable running with low noise and long life. it is much stronger

than other factory with 1mm or 2mm thickness frame.

than other factory with 1mm or 2mm thickness frame.

Equipment List

Jacket Dissolving cooker with mixer and scraper

Jacket cooling tank with mixer and scraper

Jacket storage tank with mixer and scraper

Transportation lobe pump ( Durrex)

Jacket transportation pipe

control cabinet (Siemens /Schneider )

PLC control Depositing unit (one color, double color side by side , sandwich gummy all can be one shot deposited)

Cooling tunnel ( optionally control temperature and humidity )

Sugar coating or oil coating equipments

Jacket cooling tank with mixer and scraper

Jacket storage tank with mixer and scraper

Transportation lobe pump ( Durrex)

Jacket transportation pipe

control cabinet (Siemens /Schneider )

PLC control Depositing unit (one color, double color side by side , sandwich gummy all can be one shot deposited)

Cooling tunnel ( optionally control temperature and humidity )

Sugar coating or oil coating equipments

Model | GD150Q | GD300Q | GD450Q | GD600Q | |||

Capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h | |||

Candy Weight | According to the size of candy | ||||||

Depositing Speed | 25~55n/min | ||||||

Total Power | 16kW/380V | 26kW/380V | 32kW/380V | 36kW/380V | |||

Total Length | 18m | 20m | 20m | 22m | |||

Total Weight | 3000kg | 4500kg | 5000kg | 6000kg | |||

Candy Samples

Our Advantages

1. Quality Assurance: The whole machine is main made of stainless steel and is fully complying with food sanitation standards.

2. Customizable Solutions: We can design the machine to meet your specific needs.

3. On-time Delivery: We ensure that your order is shipped within the agreed time frame.

4. Excellent Customer Service: Our team is 24 hours online to provide assistance and support.

2. Customizable Solutions: We can design the machine to meet your specific needs.

3. On-time Delivery: We ensure that your order is shipped within the agreed time frame.

4. Excellent Customer Service: Our team is 24 hours online to provide assistance and support.

Company Profile

TGMachine is dedicated to innovating, developing, and manufacturing all types of food machines include candy machiens, chocolate machines and biscuit machines and always stands in the leader position with over 40 years experience. Most of our products are proved by CE and other authorities. TGMachine provides not only good quality production lines for different kinds of confectionery production, but also the whole solution from marketing research, factory design, machinery installation and final production, packing design etc..

Customer Cases

Certifications

FAQ

Q:Are you trading company or manufacturer ?

A:We integrate industry and trade, which is our advantage. We can give you lower price and more comprehensive service.

Q:Do you provide any recipes for the product?

A:Yes,we will provide a basic recipe. and clients can add different color and flavor on that base.

Q:What are the advantages of your product over others?

A:We are more concerned about food safety than them, so our machine can be washed with water all over the body, and the pouring part has no sanitary defects; We can adjust the configuration of the machine according to your budget / output and give you a satisfactory answer.

Q:Do you provide any recipes for the product?

A:Yes,we will provide a basic recipe. and clients can add different color and flavor on that base.

Q:What are the advantages of your product over others?

A:We are more concerned about food safety than them, so our machine can be washed with water all over the body, and the pouring part has no sanitary defects; We can adjust the configuration of the machine according to your budget / output and give you a satisfactory answer.

Contact Us

40+ years of professional production of manufacturers, worthy of your trust.

We are happy to cooperate with the new investor in food industry or experienced manufacturers. For more solution or infomation, please contact us by visit our website.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices