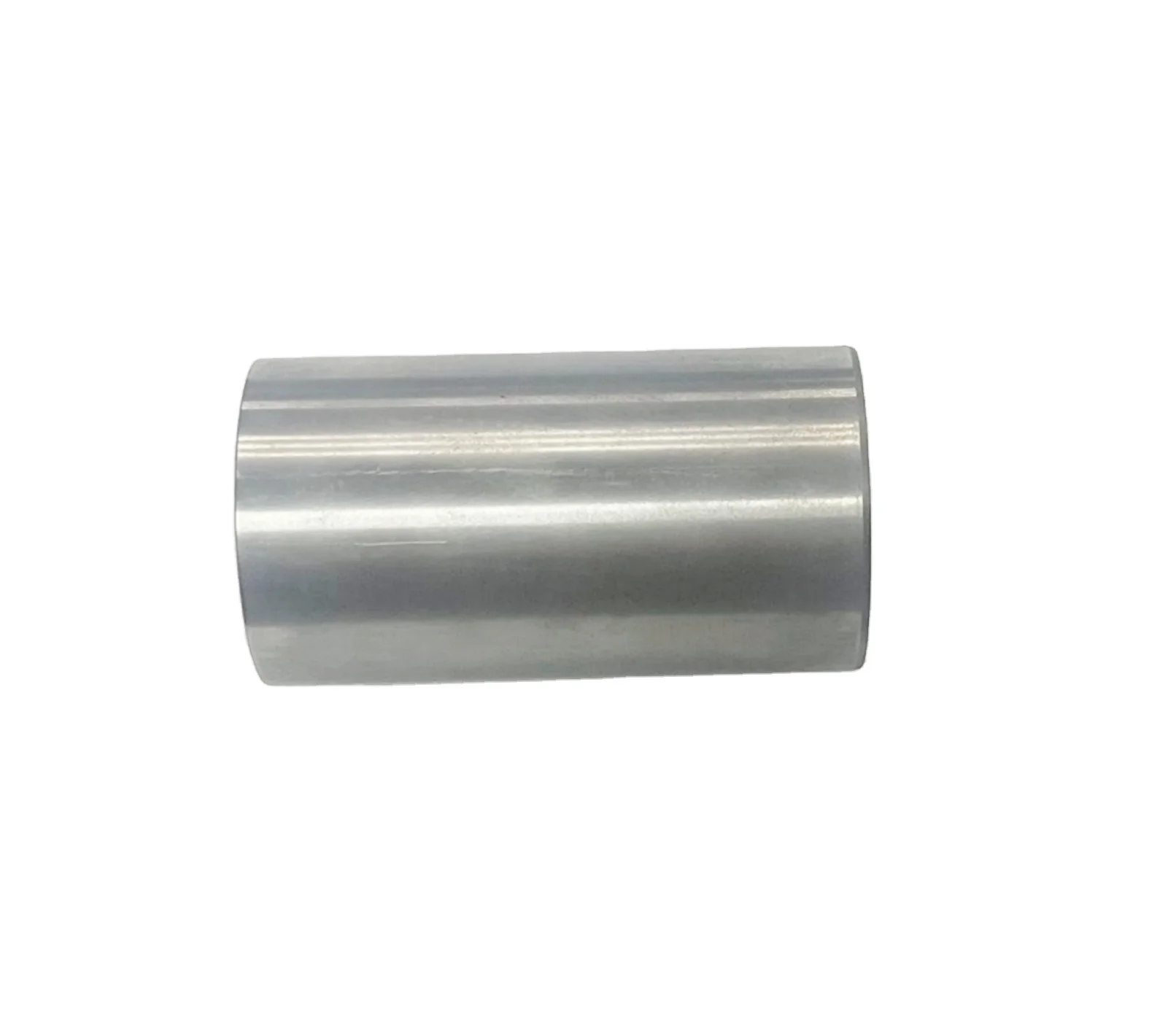

customization engine systems cylinder liner puller CSR 76.5CM Cylinder veengine cylinder liner 0.00 0.25 0.50 for Volkswagen

- Category: >>>

- Supplier: Hangzhou Wanpin Auto Parts City Xinnong Kai Firm

Share on (1601207656953):

Product Overview

Description

Product Paramenters

Product Name | cylinder liner | ||||||

warranty period | one year | ||||||

material composition | aluminum | ||||||

place of origin | AUFERAY | ||||||

brand | zhe jiang | ||||||

OEM | 0.00 | ||||||

engine type | CFB | ||||||

number of cylinders | 4 | ||||||

size | 76.5CM | ||||||

Carload consumption | 1 | ||||||

Support customization | YES | ||||||

The inner gauge of the cylinder liner is directly affected by high temperature and high pressure gas, and always has high-speed sliding friction with the piston ring and piston skirt.

The surface is in contact with the cooling water, resulting in serious thermal stress under a large temperature difference, and is corroded by the cooling water.

The side thrust of the piston against the cylinder liner not only intensifies the friction on its inner surface, but also causes it to bend. When the side thrust changes direction, the piston also strikes the cylinder liner. In addition, it is also subject to large installation preload.

The gas pressure produces tangential tensile stress and radial compressive stress on the cylinder wall, and the maximum stress is on the inner surface, which is high-frequency pulsating stress. Due to the temperature difference between the inside and outside of the cylinder wall, great thermal stress is generated, and compressive stress is generated on the inner surface and tensile stress on the cooling surface at general temperature. However, at extremely high temperature, the metal near the inner surface will creep and plastic deformation, and after cooling, residual tensile stress will form on the inner surface.

The low-frequency stress caused by the change of starting and stopping will fatigue the material

The cylinder liner should have sufficient strength, stiffness and heat resistance, and should also have good wear resistance. There should be good lubrication and cooling in the work.

The cylinder liner is generally made of wear-resistant alloy cast iron containing phosphorus or boron, such as HT25-47, HP-CuCrMo, etc. The inner surface of the cylinder liner is sometimes chromium plated (loose hole chromium plating, oil storage dot chromium plating), nitriding or phosphating to improve wear resistance. The inner surface hardness of the cylinder liner is usually required to be greater than HB200, and has a good match with the hardness of the piston ring.

The inner surface should also have appropriate roughness, so that it has a certain oil storage capacity and running-in performance. The inner surface should have sufficient roundness and cylindricity accuracy, and the installation support should have a high position accuracy facing the center of the inner hole.

The inner surface of the cylinder is easy to wear due to the action of high temperature and high pressure gas and the contact with the high-speed moving piston. In order to improve the wear resistance of cylinder and prolong the service life of cylinder, there are different cylinder structure forms and surface treatment methods. There are three types of cylinder structure: no cylinder liner type, dry cylinder liner type, wet gas cylinder liner type.

No cylinder liner type body is not inlaid with any cylinder liner body, the cylinder is directly processed on the body, the advantage is that the center distance of the cylinder can be shortened, so that the size and quality of the body can be reduced. But the cost is high.

The dry cylinder liner is not in contact with the coolant, the wall thickness is 2~3mm, the outer surface and the inner surface of the cylinder liner seat hole must be finished to ensure the necessary profile accuracy and easy disassembly. The advantages are large stiffness of the body, small center distance of the cylinder, light weight and simple processing technology. The disadvantage is that the heat transfer is poor, the temperature distribution is not uniform, and local deformation is easy to occur.

The outer wall of the wet cylinder liner is in direct contact with the coolant, the wall thickness is 5~8mm, the radial positioning is achieved by using the upper and lower positioning ring, and the axial positioning is realized by matching the upper flange of the cylinder liner with the corresponding supporting surface on the top of the body.

The advantages of wet cylinder liner are that there is no sealed water jacket on the body, easy to cast, good heat transfer, more uniform temperature distribution, easy to repair, and the cylinder liner can be replaced without removing the engine from the car. The disadvantage is that the stiffness of the body is poor and it is easy to leak.unqualified appearance.

Title goes here.

The inner hole plasma spraying process uses the atmospheric plasma spraying process to coat the powder material on the inner surface of the cylinder operation, and select different spraying powders to achieve the goals of low friction, low fuel consumption, high wear resistance and high corrosion resistance.

Title goes here.

Inner hole plasma spraying equipment

Title goes here.

It has cylinder liner heat conduction and strength analysis software, and has cylinder liner thermal conductivity test system

Title goes here.

It has cylinder liner heat conduction and strength analysis software, and has cylinder liner thermal conductivity test system

Title goes here.

Master leakage test, oil loss test, fuel loss test, power torque test technology

Title goes here.

The cylinder hole coating forms an open and dispersed porous surface after honing. It is these gently rounded holes that reduce the exposure of fuel in the combustion chamber and piston ring; At the same time, the tangential force of the oil scraping ring is reduced, so that the piston ring can enter the fluid dynamic state more smoothly, significantly reducing the friction resistance and wear, and further reducing the possibility of fuel consumption and gas channeling.

1;High bonding strength 2; Good thermal conductivity 3:Strong deformation resistance

1:Improve thermal conductivity 2:Reduce engine fuel consumption 3:Reduce cylinder hole deformation

Title goes here.

Carbon scraper ring technology/Carbon scraper ring technology

【 Function 】

Scrape away the carbon deposits that accumulate in the upper part of the piston

【 Expected effect 】

① Reduce fuel consumption

● Reduce liner inner wall wear

● Reduce the amount of oil flowing up

② Increase power

● Reduce burn loss

③ Improve durability

● The piston ring is stable

Title goes here.

Plasma ceramic strengthening technology. Plasma ceramic strengthening technology

> Principle and Features:

Using plasma surface engineering technology, the new ceramic alloy layer of Si, B and N is formed on the surface of the cylinder liner without changing the structure, which improves the hardness, oxidation resistance and corrosion resistance of the inner surface of the cylinder liner.

Low temperature growth (about 200°C), will not cause cylinder liner deformation or metallographic change;

● Ceramic material and metal mutual diffusion, solid structure, will not fall off; Does not affect the mesh structure and size;

● A self-lubricating hexagonal crystal structure BN is formed in the alloy layer, which can reduce friction;

> Principle and Features:

Using plasma surface engineering technology, the new ceramic alloy layer of Si, B and N is formed on the surface of the cylinder liner without changing the structure, which improves the hardness, oxidation resistance and corrosion resistance of the inner surface of the cylinder liner.

Low temperature growth (about 200°C), will not cause cylinder liner deformation or metallographic change;

● Ceramic material and metal mutual diffusion, solid structure, will not fall off; Does not affect the mesh structure and size;

● A self-lubricating hexagonal crystal structure BN is formed in the alloy layer, which can reduce friction;

Packing & Delivery

Brand packaging:

Our company has been focusing on engine accessories for 20 years and launched the company brand Ofre. We will complete every detail, every product quality, committed to the perfect solution to automobile engine maintenance. Let customers have a better experience.

Certifications

FAQ

1. Who are We?

Our headquarters is located in Hangzhou, China, and since the beginning of 2016, our company has been specialized in the sales of automotive engine parts.

2. How do we guarantee quality?

Always be pre-production samples before mass production;

Always carry out final inspection before shipment;

Always carry out final inspection before shipment;

3. What can you buy from us?

Engine accessories, cylinder block, cylinder head, piston, piston ring, valve, bearing bush, crankshaft, camshaft, etc.

4. Why do you buy from us and not from other suppliers?

Our company focuses on the sales of auto engine parts, covering models including Europe, America, Japan and South Korea, China auto parts. And has a large inventory for cross-border e-commerce companies to provide distribution

5. What services can we provide?

Acceptance of delivery terms: FOB, CIF;

Accepted payment currency: USD, RMB;

Payment type accepted :TT

Accepted payment currency: USD, RMB;

Payment type accepted :TT

WA Business

instagram

WeChat

We Recommend

New Arrivals

New products from manufacturers at wholesale prices