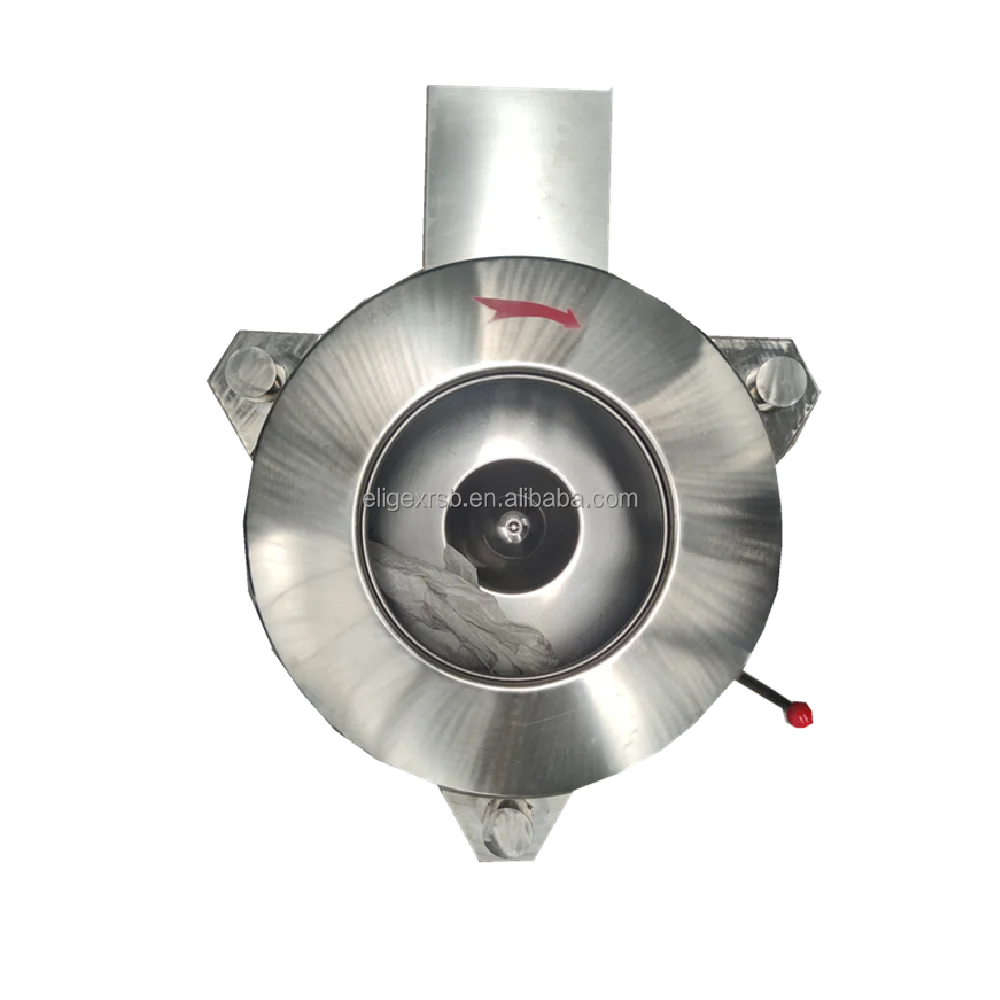

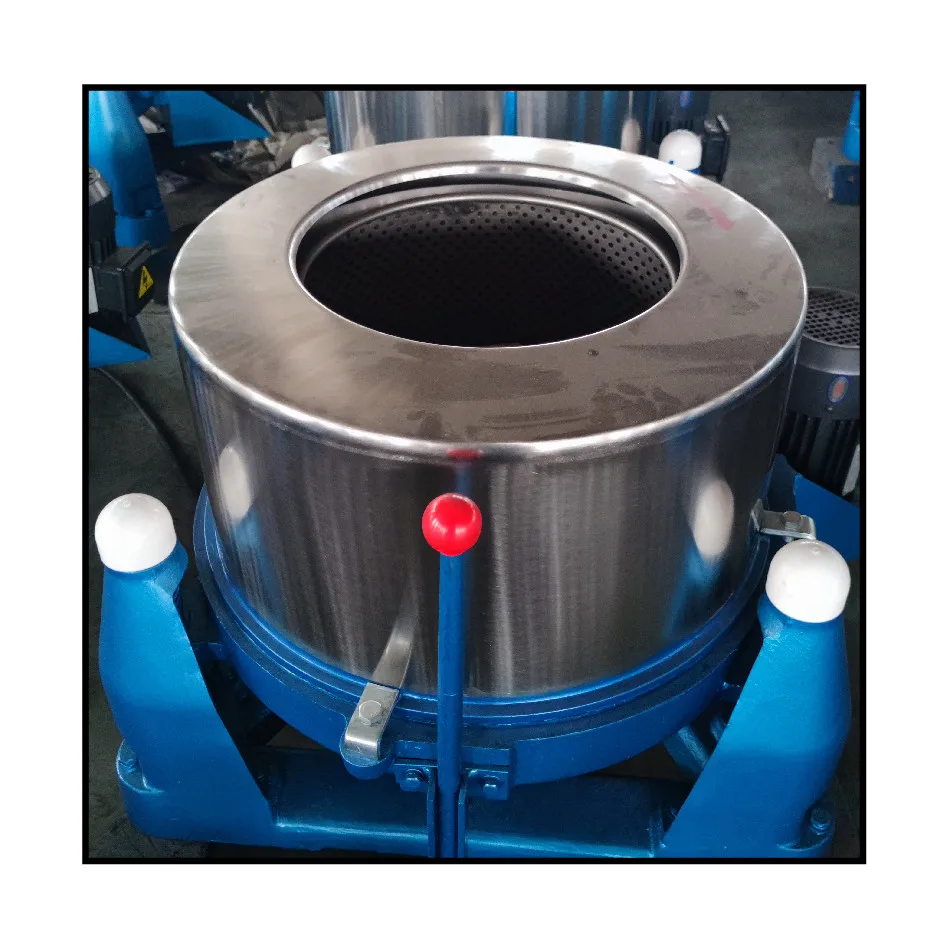

Stainless steel dehydrator, food dewaterer, textile spin drier

- Category: >>>

- Supplier: Taizhou Elige dyeing and Washing Equipment Co. Ltd.Taizhou Ltd.

Share on (1601209831314):

Product Overview

Description

Type | SS752-500 | SS752-600 | SS753-800 | SS751-1000 | SS754-1200 | SWE301-150 |

Drum diameter(mm) | 500 | 600 | 800 | 1000 | 1200 | 1500 |

Drum height(mm) | 300 | 300 | 340 | 380 | 480 | 600 |

Spindle Speed (r/min) | 960 | 960 | 910 | 900 | 700 | 750 |

Motor Power (kw) | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 11 |

Maximum capacity (kg) | 25 | 50 | 80 | 130 | 220 | 500 |

External dimension (mm) | 1000*1000*650 | 1250*1250*700 | 1500*1500*800 | 1800*1800*900 | 2000*2000*1020 | 2550*1950*1400 |

machine weight (kg) | 250 | 450 | 760 | 1100 | 1600 | 2400 |

Application Scope and structure characteristics of dehydrator

dehydrator also called centrifuge, centrifugal dehydrator, drying machine. Because of its use of high-speed operation of the huge centrifugal force and named the centrifuge, centrifugal dehydrator. The inner liner and outer shell are made of stainless steel with excellent performance. SS series dehydrator (centrifuge, centrifugal dehydrator,drying machine) simple structure, easy maintenance and low noise, brake flexible, reliable. Sme301-150 large capacity dehydrator is controlled by imported frequency conversion, equipped with in-out device, with large capacity, small energy consumption and perfect anti-vibration, timing, automatic and safety control system.

A, The working principle of the dehydrator, the main component of the dehydrator is the liner, liner around the cloth with small holes, clothes to be dehydrated on the liner. The motor drives the tank to rotate at high speed through the belt. A large centrifugal force is generated, and the water is thrown out through a small hole in the liner and collected for uniform discharge. In general, for wet clothes, the dryer work for two minutes to achieve almost the same effect as the dryer work for 20 minutes to achieve the same effect, but the dryer can not completely dry clothes. So, a way to save time and energy is to dehydrate wet clothes first, and then dry them.

B, The use of dehydration machine, industrial dehydration machine is mainly used for all kinds of textile (needle) fabrics,

clothing, chemical raw materials, latex products, etc. , it is widely used in textile, printing and dyeing, clothing, hotels,

hospitals, chemical and latex products and other enterprises and institutions.

C, The dehydration machine structure characteristic

A, The working principle of the dehydrator, the main component of the dehydrator is the liner, liner around the cloth with small holes, clothes to be dehydrated on the liner. The motor drives the tank to rotate at high speed through the belt. A large centrifugal force is generated, and the water is thrown out through a small hole in the liner and collected for uniform discharge. In general, for wet clothes, the dryer work for two minutes to achieve almost the same effect as the dryer work for 20 minutes to achieve the same effect, but the dryer can not completely dry clothes. So, a way to save time and energy is to dehydrate wet clothes first, and then dry them.

B, The use of dehydration machine, industrial dehydration machine is mainly used for all kinds of textile (needle) fabrics,

clothing, chemical raw materials, latex products, etc. , it is widely used in textile, printing and dyeing, clothing, hotels,

hospitals, chemical and latex products and other enterprises and institutions.

C, The dehydration machine structure characteristic

1, The industrial dehydration machine all is the three feet suspension type structure, may avoid in the rotation lobster sauce internal load unbalance produces the foundation vibration in the movement.

2.The shell and the rotating lobster sauce are made of stainless steel plate, the cage base and the chassis are made of cast iron material, and the water outlet pipe is under the chassis.

3.The spindle is made of high quality steel after heat treatment.

4.The transmission part is driven by triangle tape, and the centrifugal starting wheel is driven directly by the motor, which can make the machine start slowly and reach the designed speed step by step, so as to ensure the smooth running of the machine.

5, The machine has brake open and close arm, brake performance is good. It can stop the machine quickly.

Q: Why choose Us?

A: First of all, we are a professional factory with rich experience in production and export. Make sure you buy from a real professional manufacturer, where you can get competitive prices. We ensure that all qualified products meet high quality international standards. Second, as experienced exporters, we can provide professional advice on transportation methods to reduce your costs.

Q: How Do I Know My Order status?

A: After receiving the down payment, we will send you a financial confirmation letter of payment. If necessary, you will receive letters and photos from the production, quality and packaging departments so that you know about your order.

Q: How Do I get urgent feedback?

A: If you need to contact us urgently, please call us at + 86-18921744020. You can also send email and wechat to our business specialist, we will provide 24-hour online service.

Q: What is your sample policy?

A: As our products are large-scale goods, we regret that we can not provide you with samples free of charge, but we will have flexible first order discount prices. In addition, if you need to customize the product or new product development proofing, you need to pay additional proofing fee and freight.

Q: What is the sampling time?

A: According to the samples, we will confirm the length of the production cycle according to your requirements, and communicate with you as soon as possible, but if we have samples on hand, we can send it to you as soon as we receive the payment.

Q: Can I print my logo on the package?

A: Of course. Customizable packaging and OEM printing.

A: First of all, we are a professional factory with rich experience in production and export. Make sure you buy from a real professional manufacturer, where you can get competitive prices. We ensure that all qualified products meet high quality international standards. Second, as experienced exporters, we can provide professional advice on transportation methods to reduce your costs.

Q: How Do I Know My Order status?

A: After receiving the down payment, we will send you a financial confirmation letter of payment. If necessary, you will receive letters and photos from the production, quality and packaging departments so that you know about your order.

Q: How Do I get urgent feedback?

A: If you need to contact us urgently, please call us at + 86-18921744020. You can also send email and wechat to our business specialist, we will provide 24-hour online service.

Q: What is your sample policy?

A: As our products are large-scale goods, we regret that we can not provide you with samples free of charge, but we will have flexible first order discount prices. In addition, if you need to customize the product or new product development proofing, you need to pay additional proofing fee and freight.

Q: What is the sampling time?

A: According to the samples, we will confirm the length of the production cycle according to your requirements, and communicate with you as soon as possible, but if we have samples on hand, we can send it to you as soon as we receive the payment.

Q: Can I print my logo on the package?

A: Of course. Customizable packaging and OEM printing.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices