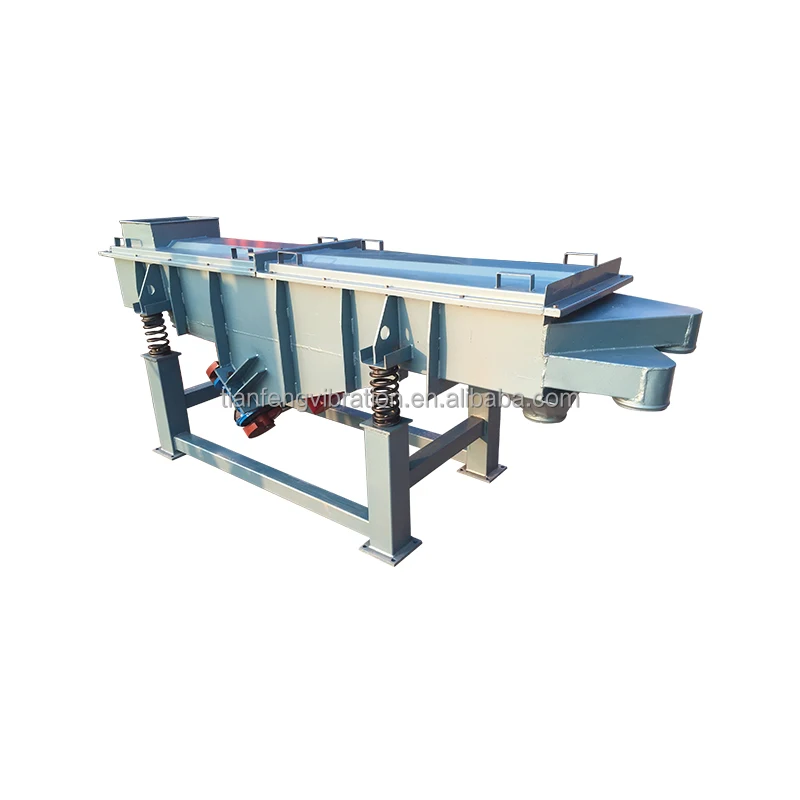

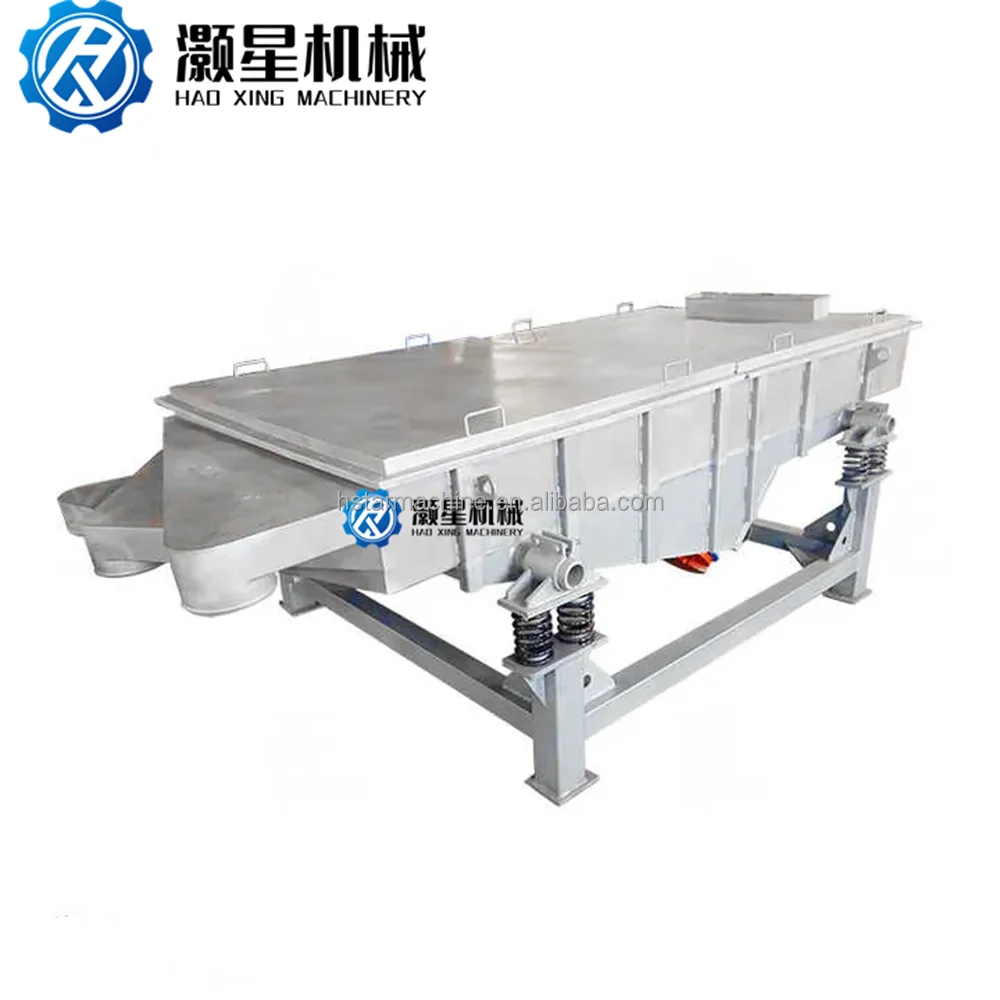

Stainless steel type industrial sifters rock salt linear vibrating screen separator

- Category: >>>

- Supplier: Xinxiang Tianfeng Vibration Machinery Co. Ltd.Xinxiang Ltd.

Share on (1601212988906):

Product Overview

Description

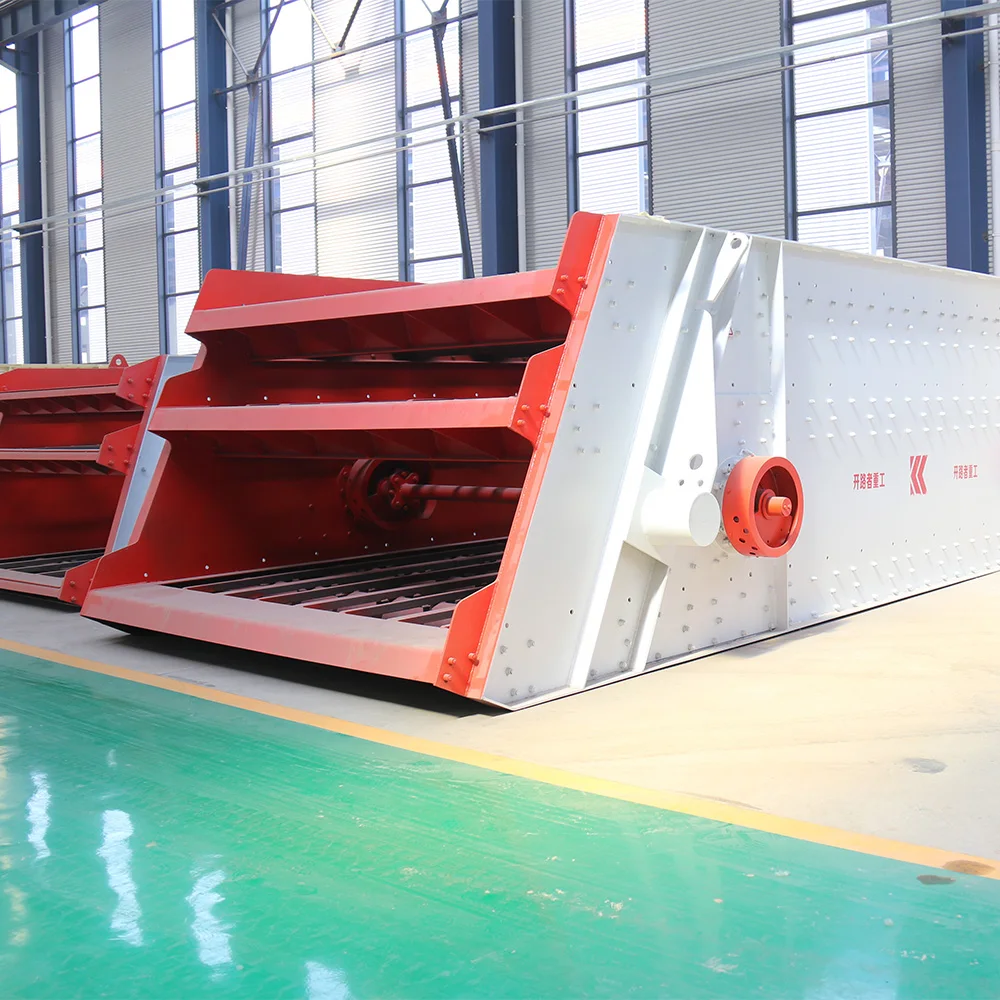

Small Scale Hard Stone Limestone Silica Sand Gold Mining Coal Linear Vibrating Screen Machine With Good Price

Product Parameters

Model | Screen surface area (㎡) | Screen surface inclination (°) | Mesh size (mm) | Processing capacity (t/h) | Vibration times | Double amplitude (mm) | Power (kw) | Weight (kg) |

T LZS 924 | 2.16 | 0-10 | ~50 | ~130 | 960 | 4 ~7 | 2x0.75 | 1500 |

2TLZS 924 | 2.16 | 0-10 | ~50 ~60 | ~100 | 960 | 4 ~8 | 2x1.5 | 1700 |

T LZS 1230 | 3.6 | 0-10 | ~50 | ~180 | 960 | 4 ~8 | 2x2.2 | 2300 |

2TLZS 1230 | 3.6 | 0-10 | ~50 ~30 | ~150 | 960 | 4 ~7 | 2x2.2 | 2650 |

T LZS 1536 | 5.4 | 0-10 | ~80 | ~380 | 960 | 4 ~8 | 2x3.0 | 3400 |

2TLZS 1536 | 5.4 | 0-10 | ~80 ~50 | ~300 | 960 | 4 ~8 | 2x3.0 | 4000 |

T LZS 1540 | 6 | 0-10 | ~120 | ~400 | 960 | 4 ~9 | 2x3.7 | 4200 |

2TLZS 1540 | 6 | 0-10 | -120 ~80 | ~350 | 960 | 4 ~9 | 2x3.7 | 5100 |

2TLZS 1860 | 10.8 | 0-10 | ~120 | ~600 | 960 | 4 ~9 | 2x5.5 | 5210 |

Company Profile

About us

Xinxiang Tianfeng Vibration Machinery Co., Ltd. is a professional enterprise that produces and develops vibration, screening, and conveying equipment. The screening equipment produced by our company has advantages such as high screening efficiency, large processing capacity, and low noise. The company mainly focuses on three series of fine screening, conveying and feeding, and large screening machines, including the TS series three-dimensional rotary vibration screen, FYB series square swing screen, YBS series circular swing screen TLZS series linear vibrating screen, TS series vibrating straight row screen, ZKS series vacuum feeding machine, and other products are widely used in the building m aterials, chemical, medical, food, and mining industries, achieving rapid separation and filtration of various materials.

We constantly improve product quality and cost-effectiveness, obtaining many honors and patent certificates. Our professional production and sales team always prioritize customer needs and provide them with customized solutions.

We constantly improve product quality and cost-effectiveness, obtaining many honors and patent certificates. Our professional production and sales team always prioritize customer needs and provide them with customized solutions.

Order receiving process

Step 1--- Placing order& Paying deposit ( before production)

Step 2--- Arranging production& Contact freight forwarder to book space

Step 3--- Completing the final payment (two days before the end of the production)

Step 4--- Informing the transportation company to transport goods to the port

Step 5--- Marking the corresponding English name for each product and product parts with marker

Step 6--- English version of the product instructions will be put in the cargo box.

Step 7--- Sending videos and pictures of factory to customers

Step 2--- Arranging production& Contact freight forwarder to book space

Step 3--- Completing the final payment (two days before the end of the production)

Step 4--- Informing the transportation company to transport goods to the port

Step 5--- Marking the corresponding English name for each product and product parts with marker

Step 6--- English version of the product instructions will be put in the cargo box.

Step 7--- Sending videos and pictures of factory to customers

FAQ

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union

remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union

remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices