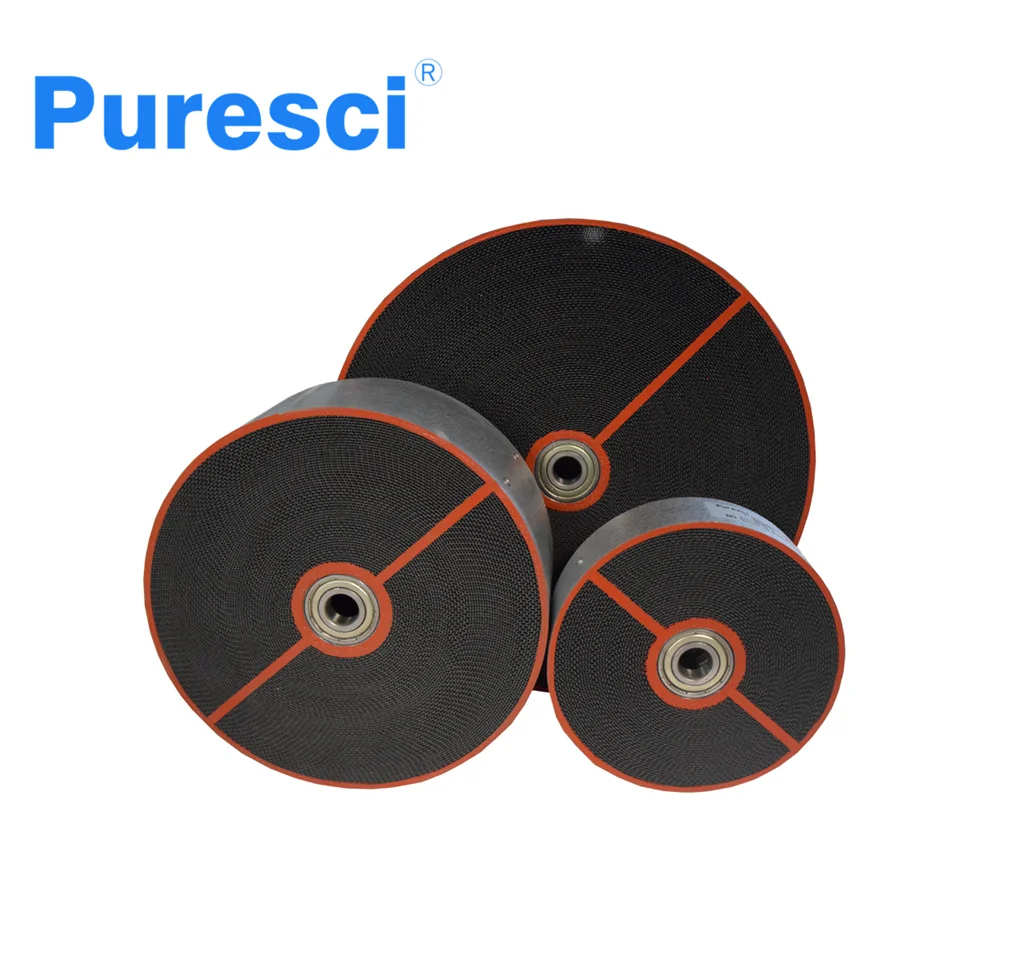

Economic Wide Range Of Specifications Silica Gel Desiccant Rotor For Dehumdifiier System

- Category: >>>

- Supplier: Puresci Environment Technology LimitedPuresci Limited

Share on (1601215683787):

Product Overview

Description

Products Description

PSS Regular Desiccant Rotor

PSS rotor is used for normal humidity and low dew point operation in high regeneration temperature (90-150℃), and suitable for most dehumidification applications.

It is cost-effective and with good dehumidification performance in wide range of applications.

General Partition 1 : 3

Features

1. Unique Moisture Adsorption

Relative humidity 10% ~ 40% or Dew point -50℃ ~ -80℃

2. Advanced Manufacturing Techniques

Axis Perpendicularity error precision ±0.1mm(Below 1500mm), ±0.2~0.3mm(1500~3000mm),

Improved tightness to reduce friction and the probability of rotor cracking.

3. Professional Surface Treatment

Adopt international standard environmental paint with water-resistance, high temperature resistance, strong weather resistance, anti-corrosion, no odor and high hardness.

4. High Surface Strength

500N/㎝²{50kgf/㎝²}

5. Water Washable

Silica gel does not dissolve in water and any solvent. Non-toxic and tasteless.

Therefore, rinse and maintain with water and organic solvent.

6. Variety Construction

It is recommended that using the split type for diameter ≥ 2200mm, due to delivery conditions.

It's easy way to assemble upper and lower parts on site.

If the space for delivery or assemble is limited, the rotor can be split into small pieces in the shape of fans.

7. Long Life Service

We made the life test and calculated service life according to Arrhenius Theoretical Formula.

As the combination of repeated experiments and accurate theoretical calculation, service life can be as long as 10 ~ 12 years in good environment.

Products Structure and Dimensions

Besides standard dimensions (Diameter and Thickness), non-standard rotors can be customized according to customers' requirements, such as 50mm, 100mm and 150mm.

The bearing can be customized according to customers' requirements if the bearings in the following picture are not your choice.

ROTOR SIZE | ||||||

Diameter(mm) | Thickness(mm) | Bearing/ Inner hole | Shaft Diameter(mm) | |||

180-400 | 50, 100, 150, 200, 300, 400 | 6204/20 | 53 | |||

440 | 300, 400 | 6204/20 | 53 | |||

500 | 200, 300 | 6204/20 | 53 | |||

450, 550 | 100, 200, 300, 400 | 6204/20 | 53 | |||

650-770 | 200, 300, 400 | 6204/20 | 70 | |||

850 | 200, 300, 400 | 6204/20 | 100 | |||

900 | 200, 300 | 6204/20 | 100 | |||

965-1050 | 200, 300, 400 | 6204/20 | 100 | |||

1220-1370 | 200, 300, 400 | 6206/30 | 150 | |||

1525-1800 | 200, 300, 400 | 6206/30 or 6208/40 | 150/240 | |||

1850 | 200, 300 | 6206/30 or 6208/40 | 240 | |||

1940-2190 | 200, 300, 400 | 6208/40 or 6206/30 | 240 | |||

2200-2400, 2550 | 200, 300 | 6208/40 | 240 | |||

2450-2600 | 200, 300, 400 | 6208/40 | 240 | |||

Accessories - Cassette, Flange, Sealing strip etc

Cassette's material

(1) Mild steel tube, high-temperature painting

(2) Stainless steel square tube

Motor

Applicable environment is -10℃ ~ 40℃, Motor can be customized.(220V/380V)

(1) Mild steel tube, high-temperature painting

(2) Stainless steel square tube

Motor

Applicable environment is -10℃ ~ 40℃, Motor can be customized.(220V/380V)

Flange

If the rotor is equipped with flange, It's available for:

(1) Galvanized steel flange: 30*30mm, 40*40mm or 50*50mm

(2) Stainless steel flange: 30*30mm, 40*40mm or 50*50mm

(2) Stainless steel flange: 30*30mm, 40*40mm or 50*50mm

Sealing Strip

When the rotor is equipped with cassette, the sealing strip is necessary to avoid air leakage.

Product Packing and Shipping

The rotor are packed with wooden case and foam of 5 cm thickness. Don't worry about the damage in delivery.

Via Sea, Air or Express such as UPS/ DHL/ FEDEX.

Tracking NO. will send to you via Email/Whatsapp/Wechat after samples or goods are shipped out.

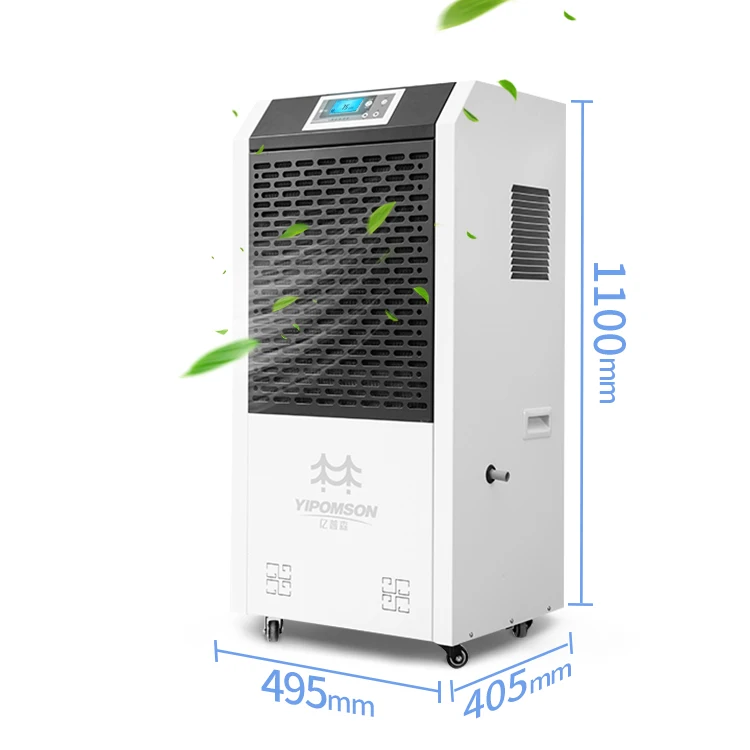

Application

Ship manufacturing and bridge corrosion resistance;

Storage and maintenance for electronic manufacturing;

Plastic products manufacturing and drying;

Food producing, processing and storing;

Our Service

1. Pre-sale Service

(1) Technical service consultation.

(2) Web and App for product selection.

( //selection.puresci.com)

(3) Support service - product test, system design, R&D technical support.

2. In-sales Service

Precision production facilities and consummate production technology is a guarantee of high quality.

3. After-sales Service

Timely delivery, quickly help customers solve technical problem and optimize equipment performance, ensure terminal customers to for dehumidification equipment efficiency.

Company Profile

FAQ

Q1: What's your temrs of trade?

EXW, FOB, CFR, CIF, DDU, DDP.

Q2: What's your terms of payment?

T/T, L/C, Western Union or Paypal.

Q3: How about your delivery time?

It is 7 days normally. The specific delivery time depends on the items and the quantity of your order.

Q4: What's your terms of packing?

The package of desiccant rotor is polyfoam and wooden case. It will be very safe for shipping.

Q5: Can you produce according to the samples?

Generally, we offer customized services.

Q6: What's your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay sample cost and courier cost.

Thanks for your attention! If you are interested in our products, please do not hesitate to contact

me. Welcome for your inquiry!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices