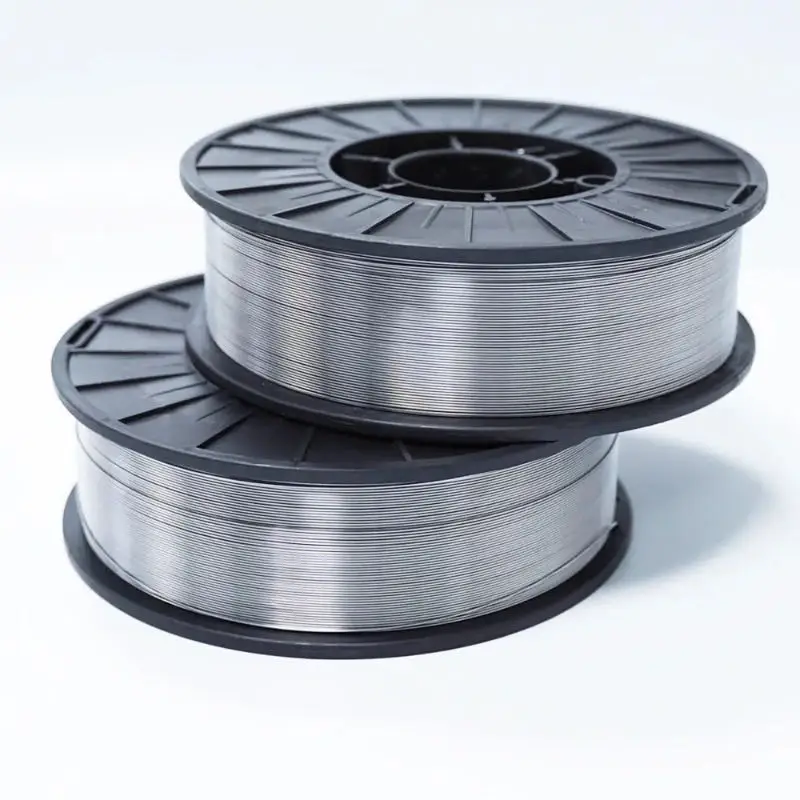

inconel 625/alloy 625/ERNiCrMo 3 Mig welding wire nickel alloy welding wire 0.5mm

- Category: >>>

- Supplier: Shanghai Tankii Alloy Material Co. Ltd.Shanghai Ltd.

Share on (1601219785770):

Product Overview

Description

inconel 625/alloy 625/ERNiCrMo-3 Mig welding wire nickel alloy welding wire 0.5mm

Weling series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Chemical Composition:

| Grade | % | Ni | Cr | Fe | Mo | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

| Alloy 625 | Min | 50 | 17 | Rest | 2.8 | 4.75 | ||||||||

| Max | 55 | 21 | 3.3 | 5.5 | 10.0 | 0.08 | 0.35 | 0.35 | 0.015 | 0.3 | 0.8 | 1.15 |

Minimum mechanical properties in the room temperature:

| Alloy | Tensile strength Rm N/mm² | Yieldstrength R P0. 2 N/mm² | Elongation(%) | Brinell hardness HB |

| 625 | 760 | 345 | 30 | ≤220 |

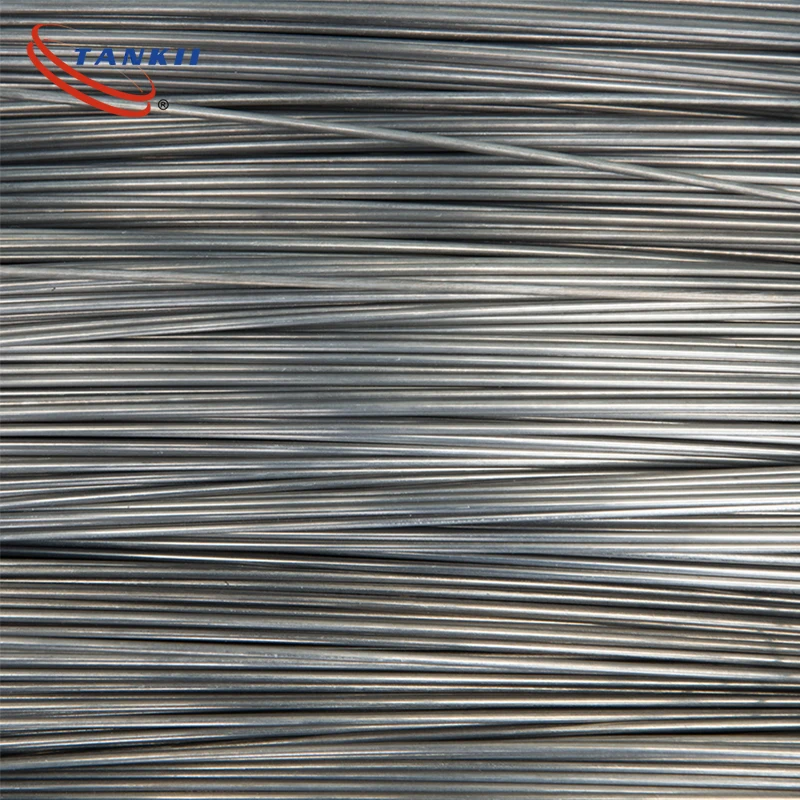

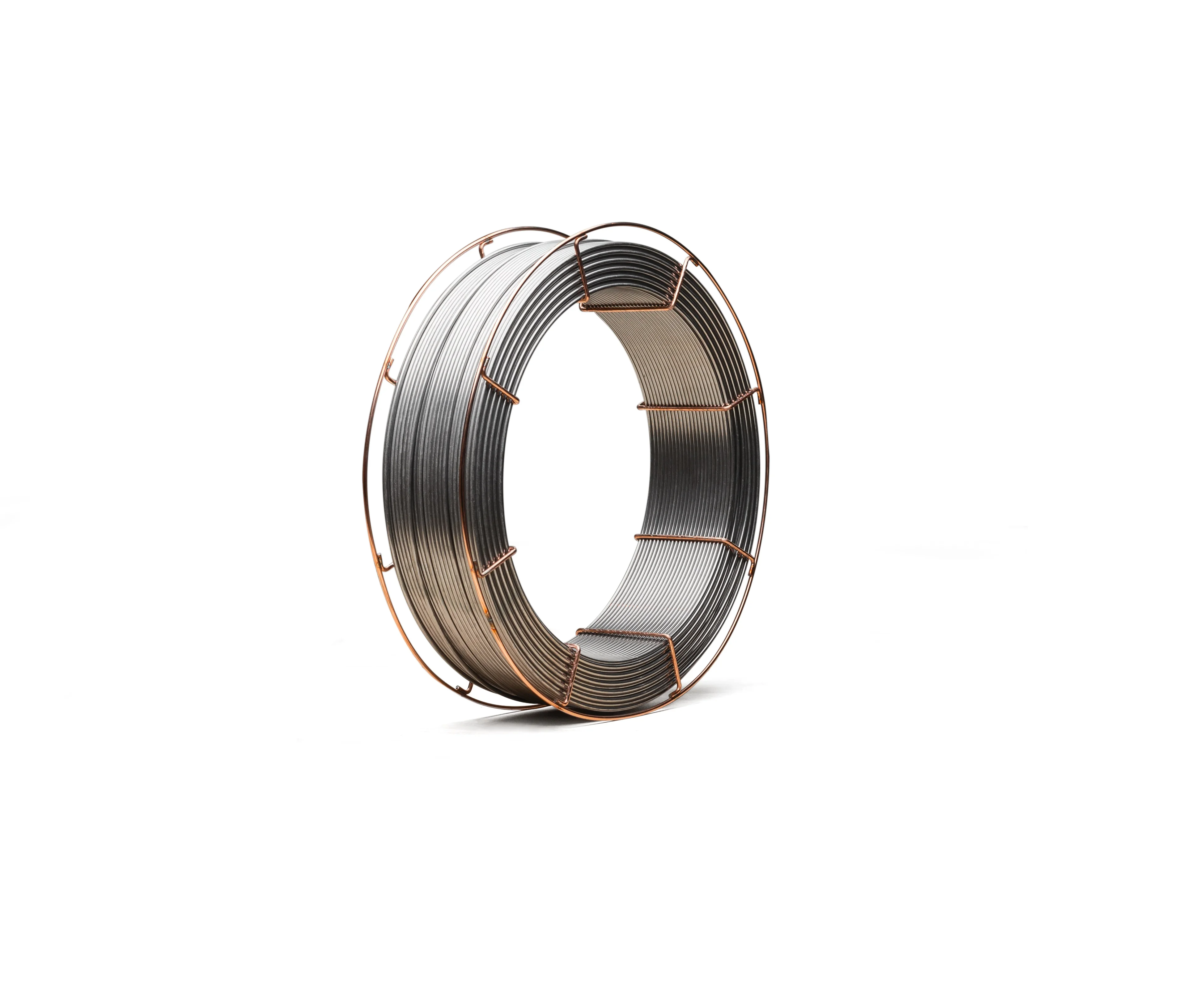

ERNiCrMo-3 is a nickel-chromium-molybdenum wire primarily utilized for welding alloys 625, 601, 802, and 9% nickel using the gas arc metal and gas tungsten arc method of welding. ERNiCrMo-3 delivers moderate strengths, good fabricability, and superior corrosion resistance from cryogenic to elevated (up to 1800°F) temperatures. It also features good oxidation resistance. Pinnacle Alloys ERNiCrMo-3 is designed for welding NiCrMo to itself, to steel, to other nickel-base alloys, and for cladding steel with NiCrMo weld metal. This wire is well suited for welding piping systems and reactor components in the power generation industry and for high temperature service in a wide variety of other engineering applications including furnace equipment and petrochemical plants and in marine and

offshore environments.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices