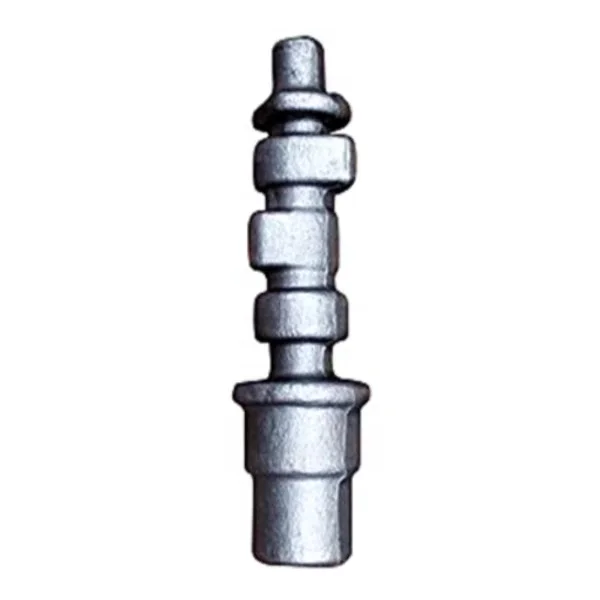

Customized Forged Alloy Steel Shaft for Compress Automobile Engine Made Durable Aluminium Carbon Steel Forging Services Included

- Category: >>>

- Supplier: Henan Forging Emperor Industry Co. Ltd.Henan Ltd.

Share on (1601220735011):

Product Overview

Description

Products Description

1 | Item Name | Custom forging parts |

2 | Size | As per approval product drawings |

3 | DRW Format | DWG, PDF, IGS, STEP, SLDPRT, SLDDRW, PRT, DRW, DXF, X_T, etc. |

4 | Weight | 0.1-200kg |

5 | Material | Different types of Steels, Carbon Steel, Stainless Steel, Alloy Steel etc; Aluminum alloy, copper alloy, titanium alloy, tungsten molybdenum alloy and other non-ferrous metals. |

6 | Application | Industry Equipments, Autos, Construction machinery Parts, Agricultural machinery, Railway relevant Parts, Petrochemical machinery, Mining machinery, The power industry. |

7 | Quality Control | 1. Raw Materials Test, include chemical composition and size; |

2. Random inspetion during production; | ||

3. Final products size test, with measurement tools, special gauges and coordinate instrument if needed; | ||

4. Final products Strenght and Hardness test, to guarantee the mechanical property; | ||

5. Assembly and Function test, with special testing gauges; | ||

6. Packing test. | ||

8 | Packing | Plastic bags, Cartons, Racks, Plywood Cases etc. |

9 | Logistics | Shipping, Air Flight, International Express etc. |

10 | Process | Die Forging, Free Forging, Hot forging, Cold forging, Heat Treatment, Machining, Surface Treatment etc. |

11 | Service | Custom OEM/ODM metal parts processing, Whole Product assembly, 2D & 3D drawings design, International Delivery Logistics, Service before & after sales etc. |

Product packaging

Packing

Plastic bags, Cartons, Racks, Plywood Cases etc.

Logistics

Shipping, Air Flight, International Express etc.

Company Profile

PROFESSIONAL FORGING SUPPLIER - FORGING EMPEROR

Henan Forging Emperor Industry Co., Ltd., headquartered in the historic city of Luoyang, China — renowned as an ancient capital and a significant industrial hub — specializes in the manufacturing of forging components. This location is not only steeped in rich cultural heritage but also serves as a vital industrial base in China, home to numerous prestigious national research institutions that contribute critical technological support and services to the evolution of our industry's value chain. Our core competencies encompass the design and production of mechanical parts through precision forging and machining processes, specializing in automotive components and custom-engineered mechanical parts. Additionally, we are dedicated to the research and development of advanced alloy forging solutions.

The factory has complete production equipment, the hot die forging pressure models are 300T, 400T, 630T, 1000T, 1600T, 2500T, 4000T and other different tonnage forging press, suitable for the production of forging parts weight from 0.05 kg to 50 kg. Equipped with over 30 units of high-precision CNC lathes and machining centers, we can guarantee the efficient post-forging machining processes required for batch production. Our capabilities extend to producing a wide array of materials, including carbon steel, alloy steel, copper, aluminum, stainless steel, titanium alloy, and tungsten-molybdenum alloys. These products find extensive application across various sectors, such as the automotive, construction machinery, railway locomotive, power generation, and mining machinery industries.

With over two decades of expertise in the forging industry, we have honed our skills and knowledge in the design and production of forging components. Our commitment to excellence extends to offering bespoke OEM services, where we undertake mapping, prototyping, and customization based on customer samples. From 3D modeling and mold design to forging, heat treatment, and precision machining, we manage the entire production lifecycle in-house, delivering end-to-end solution tailored to your specifications.

Our factory’s quality control arsenal comprises state-of-the-art equipment such as flaw detectors, hardness testers, spectrometers, metallographic analyzers, impact testing machines, tensile testers, and three-coordinate measuring instruments, ensuring the meticulous monitoring and control of product quality at every stage of production.

Forging equipment

The factory has complete production equipment, and the hot die forging press models are 300T, 400T, 630T, 1000T, 1600T, 2500T, 6300T and other different tonnage forging presses, which are suitable for the production of products from 0.1 kg to 200 kg.

Machining equipment

The company has more than 30 organic processing equipment, which can meet all kinds of metal parts turning, boring, milling, grinding and other processes. The machining accuracy can reach 0.002mm, which can provide high-volume machining of precision parts.

Quality control equipment

The quality control equipment of the company includes flaw detector, hardness tester, spectrometer, metallographic analysis, impact testing machine, tensile test, coordinate measuring instrument, etc., which can effectively control the quality of each product.

Our Advantages

Experienced

The company has been engaged in forging business for 20 years and has accumulated rich forging technology and experience.

Technical Team

The company has a large number of experienced forging engineers and technical works.

Forging Equipment

The company has a large number of experienced forging engineers and technical workers.

Professional Design

The company has a professional industrial design department, which can design products according to customers’ requirements or make secondary design improvement on old products to achieve optimal product.

Forging Die

The company has the ability to design and produce metal forging molds, which are the key tools in the manufacturing process of forging products. So we can control the product quality better.

Supporting Equipment

The company is equipped with CNC machining center and other machining equipment with excellent performance, which can meet the assembly requirements of customers’ products at alllevels.

Product Diversity

The company can design and produce forging products with complex structure, and the product surface is beautiful without defects.

Quality Control

The company implements strict ISO quality control system to effectively control the quality of each product.

Perfect Order Process

The company has a perfect order processing process to ensure the timely delivery of each order.

Service Team

The company has a professional business service team to provide customers with timely and comprehensive services.

FAQ

1.Which countries do you export to?

U.S.A, Germany, France, Italy, UK, Brazil, Swedish, Japan, Korea, Middle east of Asia, Thailand.

2.How long does it take to receive samples?

A) Pattern:30-45 days after order

B) Sample:30 days after pattern finishing.

C) The lead time is the general production period and does not include the transportation time.

3.New product development process.

Got tooling order and sample order with 50% deposit---Hold a meeting with the relation dept. To ensure the developing schedule---Design mold, fixture and gauge and making them in our house---mold steel buying---Machining---Inspection---Send out the sample with initial inspection report.

4.How long is the manufacturing lead time?

Mass Production: 90 days after sample approval by yours. The lead time is the general production period including the transportation time. We could make some special production arrangement effectively if customer has urgent need.

5 How to deal with the quality problem?

A.We perform APQP at an early stage in each project.

B.Our factory must fully understand the quality concerns from customers and implement product & process quality requirements.

C.Our quality professionals who perform patrol inspection in our factories.We perform final inspection before the goods are packed.

D.We have inspectors who perform final audit checks on the packed goods prior to dispatch from China.

6.Can you take responsibility for me?

Of course, I'm happy to help you! But I just take responsibility for my products. Please offer a test report, if it was our fault, absolutely we can make a compensation for you, my friend!

7.What are the payment terms?

Payment terms are negotiable and will improve for long term customers. During the initial stages, we request 50% of tooling fee in advance with the balance payable on acceptance of samples.Production orders can be negotiable. We prefer 50% deposit and the balance by T/T before sails. But sometimes T/T 15 days after sails would also acceptable.

8.Which currency can we buy in?

We can deal in USD / Euro currency / RMB.

9.How long does it take to ship goods from China by sea?

It takes about 5 weeks to European ports plus 1 week customs clearance, so you can get the container within 6 to 7 weeks. It takes about 2 weeks to east coast and 3 weeks to west coast US ports. All sea goods are shipped from Qingdao Port.

10.How long does it take to ship goods from China by air?

It takes about 7 days to all major destinations.

11.Can we visit the factory to conduct an audit?

Yes, you are welcome to visit our factory.

12.How do we retain client confidentiality?

We are happy to sign Confidentiality Agreements with customers and will honor them.

13.Is there a minimum volume of business required to conduct international purchasing?

There are no minimum volumes, but the prices of the goods, plus the fixed costs of importing makes it more economical to buy in high volumes. All potential customers will be assessed on an individual basis to determine if it appears a viable option for all parties to develop a relationship.

We Recommend

Forged Wheels 5x120

$10.00-30.00

Forged 20mm-150mm Steel Ball for Ball Mill

$715.00-730.00

Half Sphere Dished End for Fire Pits

$600.00-650.00

New Arrivals

New products from manufacturers at wholesale prices