corn flakes breakfast cereals making machine oat flaking machine make corn flakes

- Category: >>>

- Supplier: MT Machinery Inc

Share on (1601221880563):

Product Overview

Description

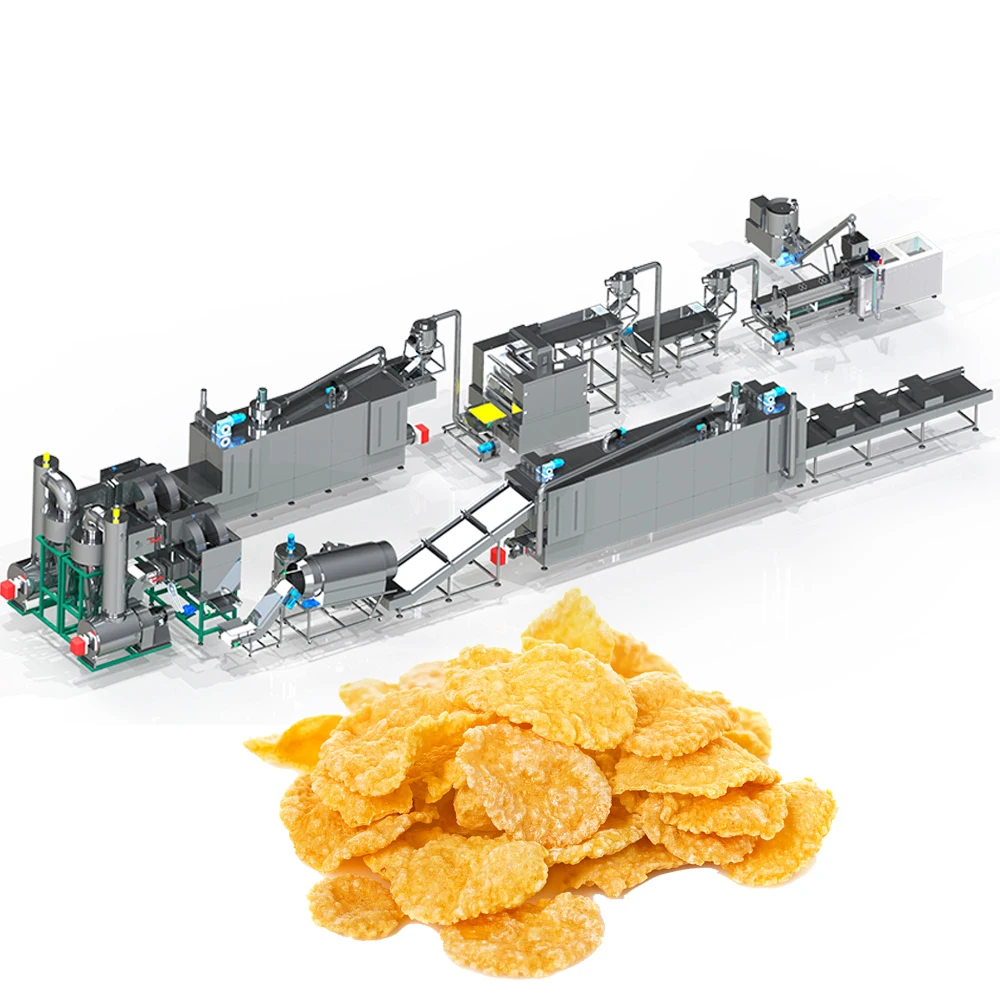

Extrusion Corn flakes Making Machine Breakfast Cereals Production Line

Products Description

Corn Flakes Making Machine

Raw materials: Usually we will offer our customers some basic formula for corn flakes, breakfast cereals snack food production.

The raw materials for corn flakes production can be corn flour, wheat flour, sugar, water, etc.

The raw materials for corn flakes production can be corn flour, wheat flour, sugar, water, etc.

Application: with strong R & D ability, our engineers offer suitable proposal as customers' requirement, factory size, and local investment. This corn flakes production line can be used to produce crispy corn flakes, coated corn flakes, natural corn flakes, fruit-oat chips, multi-grains chips and breakfast cereals with various shapes and sizes as the moulds or dies changing of Twin Screw Extruder.

Capacity: 100-500kg/hr

Capacity: 100-500kg/hr

Flow chart of corn flakes making machine

Materials preparation--Material batching--Extruding--Flaking--Pre-drying--Roasting--Coating or flavoring--Drying--Cooling--Packing--Stacking

Model | corn flakes making machine MT70 | corn flakes making machine MT75 | corn flakes machine MT80 |

Installed power | 130KW | 180KW | 220KW |

Real consumption | 95KW | 120KW | 130KW |

Capacity | 120-150KG/HR | 200-300KG/HR | 300-500KG/HR |

Details Images

Corn flakes Twin Screw Extruder.

This is the main machine of corn flakes breakfast cereals production line, which is used to extruding raw materials. It adopts

frequency speed controlling system with high automatic and stable performance.

Automatic lubricating, cooling, which guarantee machine running safely, stable and reliable.

The extruding corn grits are high quality, and good texture.

frequency speed controlling system with high automatic and stable performance.

Automatic lubricating, cooling, which guarantee machine running safely, stable and reliable.

The extruding corn grits are high quality, and good texture.

Corn flakes flatten machine

Capacity: 100-300kg/hr according to Extruder

Usage: Flaking the puffed corn granules into flatten shapes.

Advantages: PLC control system

Hydraulic system for double rollers, double motors for separate roller driving; temperature pipe is controlled evenly by infrared

sensor.

Usage: Flaking the puffed corn granules into flatten shapes.

Advantages: PLC control system

Hydraulic system for double rollers, double motors for separate roller driving; temperature pipe is controlled evenly by infrared

sensor.

Corn flakes roasting machine

The Heating source can be electric, steam and gas. All can be designed according to customer's local conditions and requirement.

Usage: drying the moisture of humid air out of extruding products, reducing the heat waste.

Drying puffed snacks after extruding or coating for next procedure.

Usage: drying the moisture of humid air out of extruding products, reducing the heat waste.

Drying puffed snacks after extruding or coating for next procedure.

Hot air roasting machine

Application: after pre-drying, the cornflakes will be roasted in this hot air roasting oven . The final corn flakes will be

crispy.

Vibrating pan with high temperature spraying tubes. The combustion chamber adopts conciliation burner.

Two separate circulating fans and cyclone dust removal device.

crispy.

Vibrating pan with high temperature spraying tubes. The combustion chamber adopts conciliation burner.

Two separate circulating fans and cyclone dust removal device.

Pet food cooling machine.

It consists of single tumbler for coating, sugar melting and spraying nozzle and elevator.

The sugar will be melted and sprayed onto the surface of hot air temperature roasted corn flakes.

Capacity is as Extruder.

Capacity is as Extruder.

Product Paramenters

Model | Pet food machine MT70 | Pet food machine MT85 | Pet food machine MT100 | Pet food machine MT135 |

Installed power | 90KW | 145KW | 170KW | 240KW |

Power consumption | 63KW | 102KW | 120KW | 165KW |

Capacity | 150-200KG/HR | 300-500KG/HR | 1000-1500KG/HR | 2000-3000KG/HR |

Production line samples

Corn Flakes Breakfast Cereals processing line produces breakfast cereals, such as O shape, ring shape, natural corn flakes and sugar coated corn flakes products with unique taste and color, which is rich in scientific nutritional ratio and digestibility.

This production line characterizes with reasonable structural design, special material, self- cleaning performance and stability. Easy operation, accurate parameter. The final corn flakes products are crispy and tasty, which is popular is market.

This production line characterizes with reasonable structural design, special material, self- cleaning performance and stability. Easy operation, accurate parameter. The final corn flakes products are crispy and tasty, which is popular is market.

Company Profile

Strict production procedure

For whole production, we take serious procedure for whole processing line after drawings are confirmed. whole production is visual, customers know each and every step of production through face talk, pictures and videos.

Our Advantages

1) 15 years of specialization in food industry.2) trust and recognition from 140 countries and regions

3) 35 patents and certificates

4) Professional technical team over 80 persons

5) large factory with over 20,000 m2

3) 35 patents and certificates

4) Professional technical team over 80 persons

5) large factory with over 20,000 m2

After everything is confirmed between customers and our engineers, production department will produce machines strictly under 6S visual management system, each step is clear with customers.After shipping, we will arrange machine installation and training service for our customers with customers' formula and local conditions.

Delivery

All machines will be wrapped by plastic bubble film on the surface first, then the spare parts will be packed in wooden case for long ship time. Everything is as request and experience.

FAQ

Q: What kinds of products can be produced by this processing line?

A: sugar coated corn flakes, natural corn flakes, breakfast cereals

Q: What's the delivery time?

A: Usually it needs 30 working days for small capacity processing line machine, for big capacity corn flakes production machinery, it gonna need around 50 working days.

Q: What about the installation service?

A: sugar coated corn flakes, natural corn flakes, breakfast cereals

Q: What's the delivery time?

A: Usually it needs 30 working days for small capacity processing line machine, for big capacity corn flakes production machinery, it gonna need around 50 working days.

Q: What about the installation service?

A: We will provide you with basic recipe for products production, engineers will visit customers' factory for machine installation, worker training.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices