Automatic Vision Screen Printer YX3070 T with Machine Vision Recognition System for SMT Production Line

- Category: >>>

- Supplier: Wenzhou Yingxing Import&Export Co. Ltd.

Share on (1601228311767):

Product Overview

Description

Product Description

Introduction

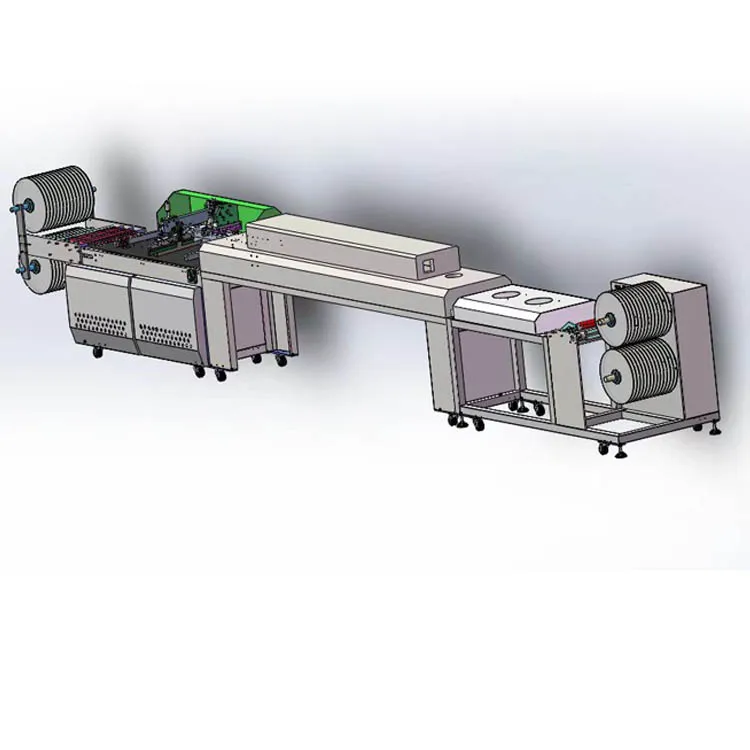

The equipment includes two sections, machinery and electric.

Mechanical section includes table alignment system, PCB transmission and its positioning system, image capture system, stencil automatic positioning system and corresponding cleaning system and solder paste removed system, etc. Electrical section includes electronic control system and control software, counter drive, stepping motor, servo motor, signal monitoring system and pneumatic system.

Feature

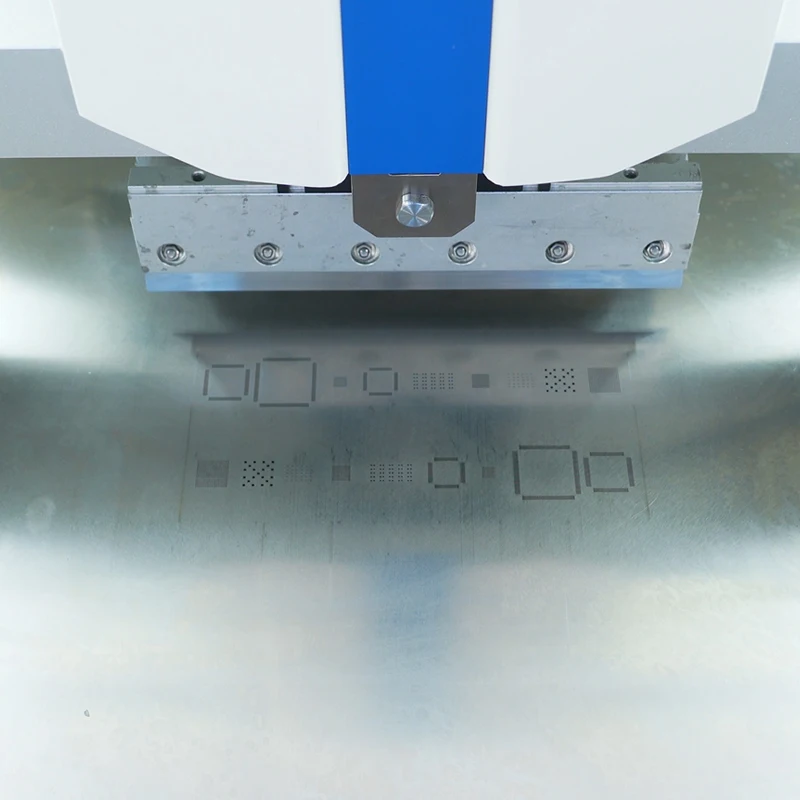

1.Advanced up/ down visual system, independent controllable and adjusted lighting, high speed mobile camera lens, precisely alignment for the PCB and template

and make sure that the printing accuracy is ±0.025mm.

2.High accurate servo motor and PC control which can insure the stability and precision of the printing. Unlimited image pattern recognition technology has the repeated positioning accuracy for ±0.01mm.

3.Suspended printing head which is designed specially in high rigid structure. The computer controls the pressure, speed and movement of the scraper, which can maintain the even and stability of the printing. The structure of scraper beam has been optimized designed. The scraper beam is light and well-formed.

3.The bottom of the board can be cleaned by manual or automatically. The clean function for the bottom of board is automatic and without assists. It can be programmed to control the dry, wet or vacuum cleaning. The cleaning time

interval can be free to choose. It can clean all the solder paste inside the board holes and insure the printing quality.

4.There is composite worktable which can set a thimble and vacuum chamber (optional) according to the size of PCB baseboard. It makes the fixture assembling more fast and easy.

5.There is a multifunctional device to deal with boards. The device can automatically positioning and pick up various size and thickness PCB boards. It has mobile magnetic thimble, vacuum platform and vacuum chamber, which can avoid board deformation effectively and insure the even of printing.

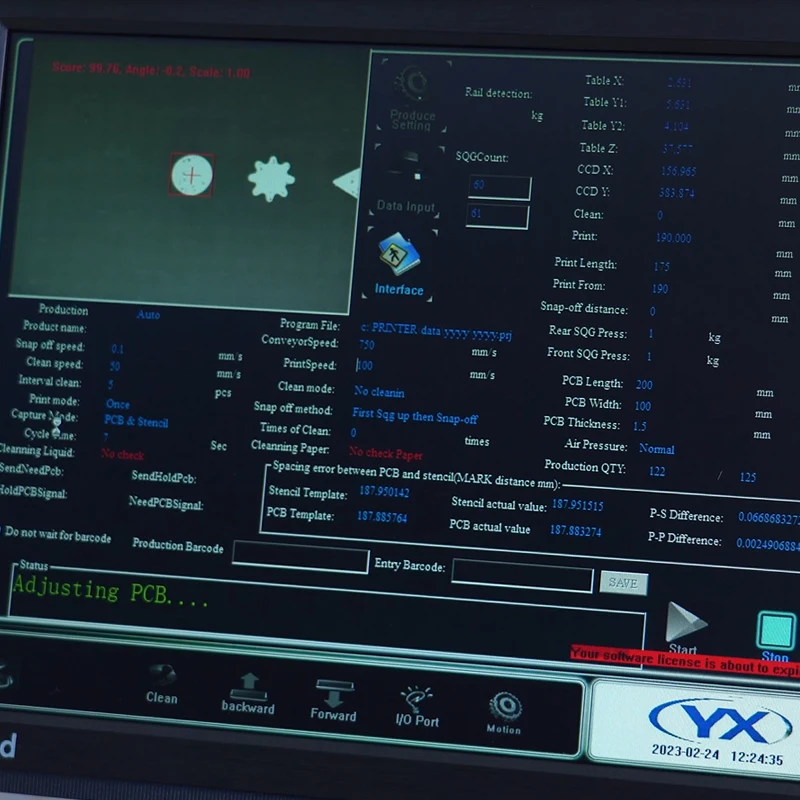

6.Windows XP operation interface and abundant software functions. Good man-machine dialogue environment, simple operation. It is easy to learn and operate.

7.Sound and light alarm function. It can indicate the reason of the fault.

8.Can deal with the PCB base board no matter it is single side or double side.

9.It can print 0.3mm spacing bonding pad perfectly.

10.2D inspection and SPC system (standard).

The YX3070-T software was developed by ourselves. The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The YX3070-T machine has one year warranty, lifetime maintenance. We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands).

The equipment includes two sections, machinery and electric.

Mechanical section includes table alignment system, PCB transmission and its positioning system, image capture system, stencil automatic positioning system and corresponding cleaning system and solder paste removed system, etc. Electrical section includes electronic control system and control software, counter drive, stepping motor, servo motor, signal monitoring system and pneumatic system.

Feature

1.Advanced up/ down visual system, independent controllable and adjusted lighting, high speed mobile camera lens, precisely alignment for the PCB and template

and make sure that the printing accuracy is ±0.025mm.

2.High accurate servo motor and PC control which can insure the stability and precision of the printing. Unlimited image pattern recognition technology has the repeated positioning accuracy for ±0.01mm.

3.Suspended printing head which is designed specially in high rigid structure. The computer controls the pressure, speed and movement of the scraper, which can maintain the even and stability of the printing. The structure of scraper beam has been optimized designed. The scraper beam is light and well-formed.

3.The bottom of the board can be cleaned by manual or automatically. The clean function for the bottom of board is automatic and without assists. It can be programmed to control the dry, wet or vacuum cleaning. The cleaning time

interval can be free to choose. It can clean all the solder paste inside the board holes and insure the printing quality.

4.There is composite worktable which can set a thimble and vacuum chamber (optional) according to the size of PCB baseboard. It makes the fixture assembling more fast and easy.

5.There is a multifunctional device to deal with boards. The device can automatically positioning and pick up various size and thickness PCB boards. It has mobile magnetic thimble, vacuum platform and vacuum chamber, which can avoid board deformation effectively and insure the even of printing.

6.Windows XP operation interface and abundant software functions. Good man-machine dialogue environment, simple operation. It is easy to learn and operate.

7.Sound and light alarm function. It can indicate the reason of the fault.

8.Can deal with the PCB base board no matter it is single side or double side.

9.It can print 0.3mm spacing bonding pad perfectly.

10.2D inspection and SPC system (standard).

The YX3070-T software was developed by ourselves. The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The YX3070-T machine has one year warranty, lifetime maintenance. We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands).

Item | Content | ||

Model | YX3070-T | ||

Screen Frames | Min Size | 370X370mm | |

Max Size | 737X737mm | ||

Thickness | 25~40mm | ||

PCB Min Size | 50X50mm | ||

PCB Max Size | 400X340mm | ||

PCB Thickness | 0.4~6mm | ||

PCB Warpage | <1% | ||

Transport Height | 900±40mm | ||

Transport Direction | Left-Right;Right-Left;Left-Left;Right-Right | ||

Transport Speed | Max 1500mm/S Programmable | ||

Board Location PCB Position | Support System | Magnetic Pin/Up-down table adjusted/supportblock by hand | |

Clamping System | Side clamping,vacuum nozzle | ||

Print Head | Two independent motorised printheads | ||

Squeegee Speed | 6~200mm/sec | ||

Squeegee Pressure | 0~15Kg | ||

Squeegee Angle | 60°/55°/45° | ||

Squeegee Type | Stainless steel(Standard), plastic | ||

Stencil Separation Speed | 0.1~20mm/sec Programmable | ||

Cleaning System | Dry、Wet、Vacuum (Programmable) | ||

Table Adjustment Ranges | X:±10mm;Y:±10mm;θ:±2° | ||

Table Adjustment Control | Table Adjustment control of linear motor | ||

Repeat Position Accuracy | ±0.01mm | ||

Printing Accuracy | ±0.025mm | ||

Cycle Time | <7s (Exclude Printing & Cleaning) | ||

Product Changeover | <5Min | ||

Air Required | 4.5~6Kg/cm2 | ||

Power Input | AC:220±10%,50/60HZ 1Φ 3KW | ||

Control Method | PC Control | ||

Machine Dimensions | 1220(L)X1355(W)X1500(H)mm | ||

Machine Weight | Approx:1000Kg | ||

Product Details

Company Information

Exhibition

Certifications

Product packaging

FAQ

Q:How is the training?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

We Recommend

New Arrivals

New products from manufacturers at wholesale prices