Copper Electrolytic equipment Cathode copper production line High purity 99.999% copper plate industrial copper plant

- Category: >>>

- Supplier: Henan Fantianliang Machinery & Equipment Co. Ltd.

Share on (1601228476687):

Product Overview

Description

Electrolytic Copper production line

Cathode copper process plant

copper upgrading plant

copper process plant

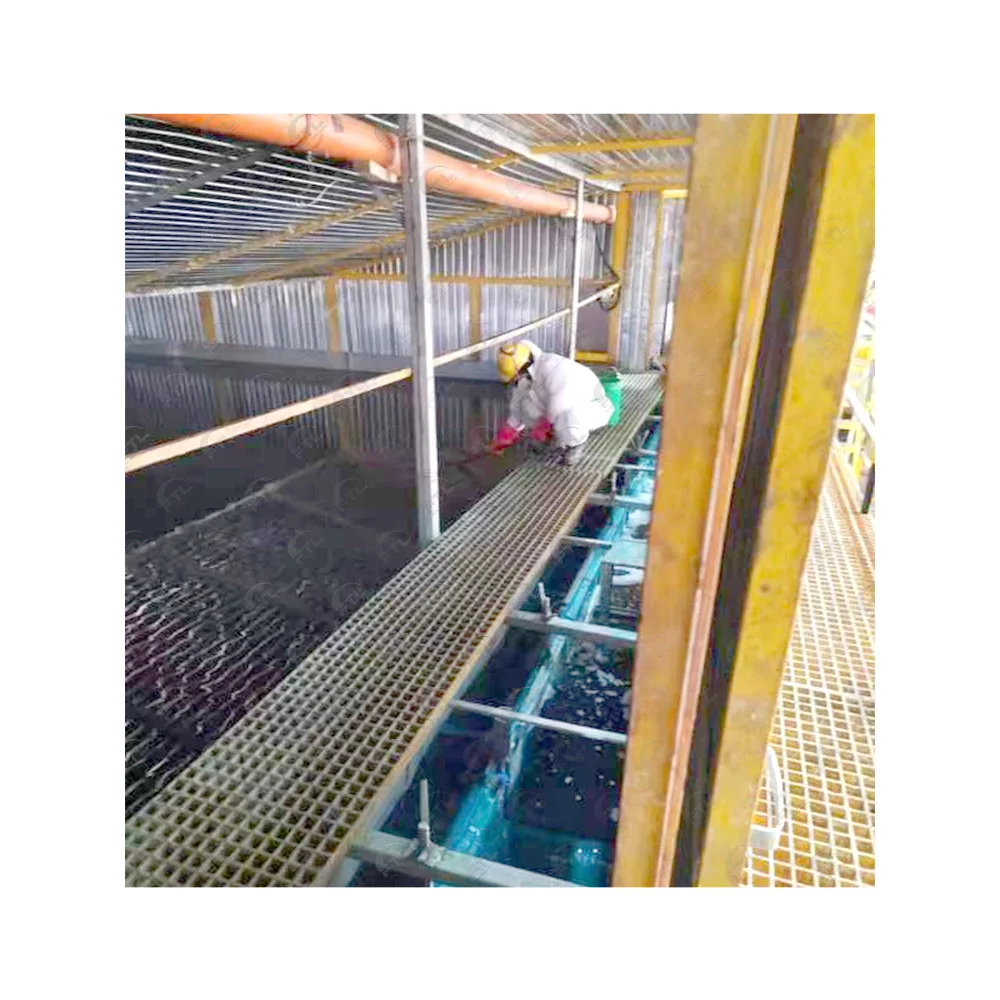

Electrolytic equipment technology is currently an internationally recognized electrochemical process method, in which crude copper electrolytic refining can reach 99.99% high-purity industrial copper. The electrolyte serves as a conductive medium, and the distiller outputs the required cell pressure for the electrolytic cell. The current is adjusted according to the actual production situation. The current is connected to the anode plate of the electrolytic cell, forming a charged positive electric field on the metal surface, and the output is passed to the mother plate. After releasing the negative electric field, copper ions are adsorbed to the negative and gradually accumulate, resulting in the precipitation of high-purity 99.995%, required electrolytic copper plates. Precious metals such as gold, silver, palladium, and platinum contained in the crude copper plate do not participate in potential electrolysis and will precipitate to form black mud at the bottom of the electrolytic cell. The so-called enriched precious metal mud is further refined through precious metal refining. The process can obtain high-quality and high-purity gold, silver, palladium, platinum, etc.

The electrolytic copper production process is a process that simplifies the operation process, improves production efficiency, and is energy-saving and environmentally friendly;

Its technical points:

1) First, add alkaline solution, flocculant, and coagulant aid to the wastewater tank containing wastewater for mixed reaction, and then enter the vortex reaction clarifier for solid-liquid separation;

2) The separated sediment is passed into the sludge tank, and the upper liquid enters the vertical flow sedimentation tank for further solid-liquid separation;

3) The separated sediment enters the sludge tank, and the upper liquid is further separated into solid-liquid or liquid-liquid by a combined gas suspension machine. The separated solid enters the sludge tank, and the upper liquid enters the clean water tank, which is filtered by activated carbon and detected before being discharged;

4) The substances collected in the sludge tank enter the filter press through the sludge screw pump, and the liquid treated by the filter press enters the waste water tank for circulation treatment, while the filter cake is transported outside;

Main Machine for Lithium Ore Processing Plant

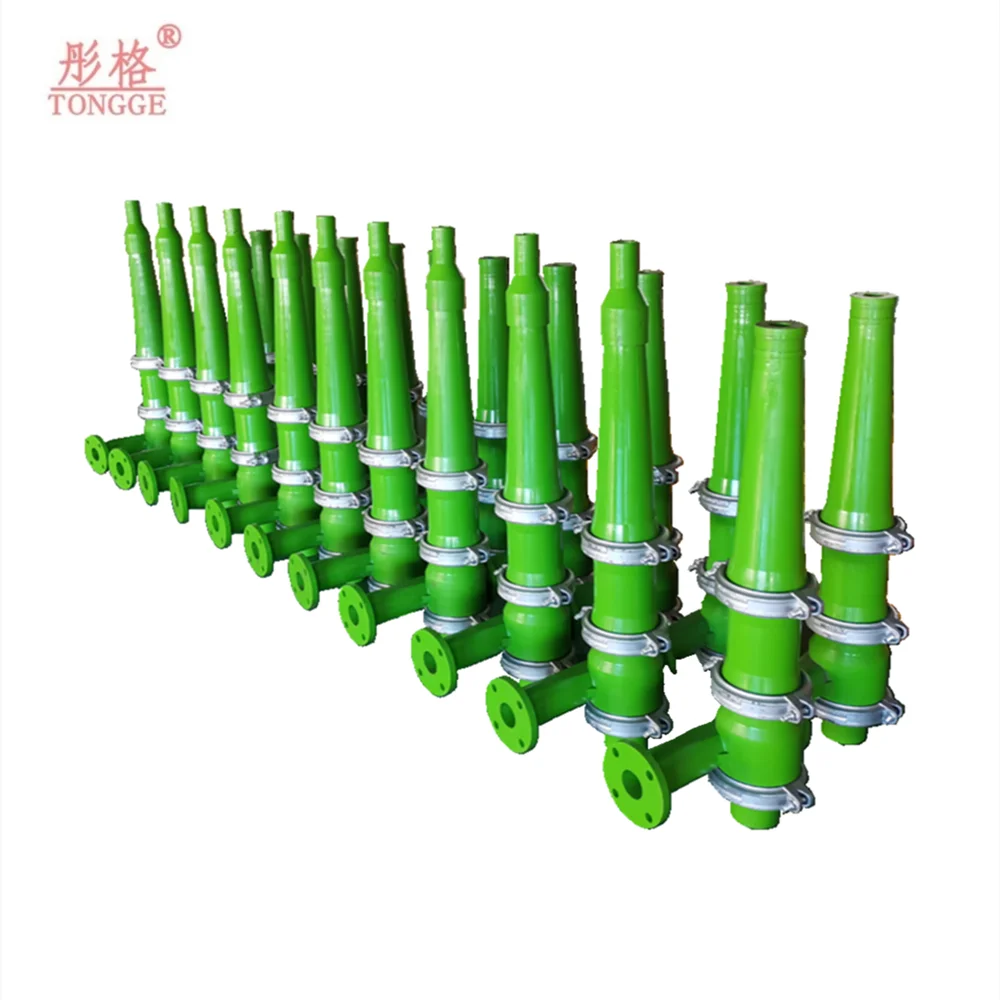

Professional equipment for lithium ore flotation technology include:

Type | Capacity | Electrolytic cell | Suggest area |

FEC100 | 100Kg/day | 2 | 15M2 |

FEC200 | 200Kg/day | 3 | 16M2 |

FEC300 | 300Kg/day | 4 | 18M2 |

FEC500 | 500Kg/day | 6 | 65M2 |

FEC800 | 800Kg/day | 8 | 200M2 |

FEC1000 | 1000Kg/day | 12 | 300M2 |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices