30 40kg/h Puffing Corn Rice Millet Grain Snack Food Making Extruder Machine

- Category: >>>

- Supplier: Lerford Machine LLC

Share on (1601229346628):

Product Overview

Description

Product Overview

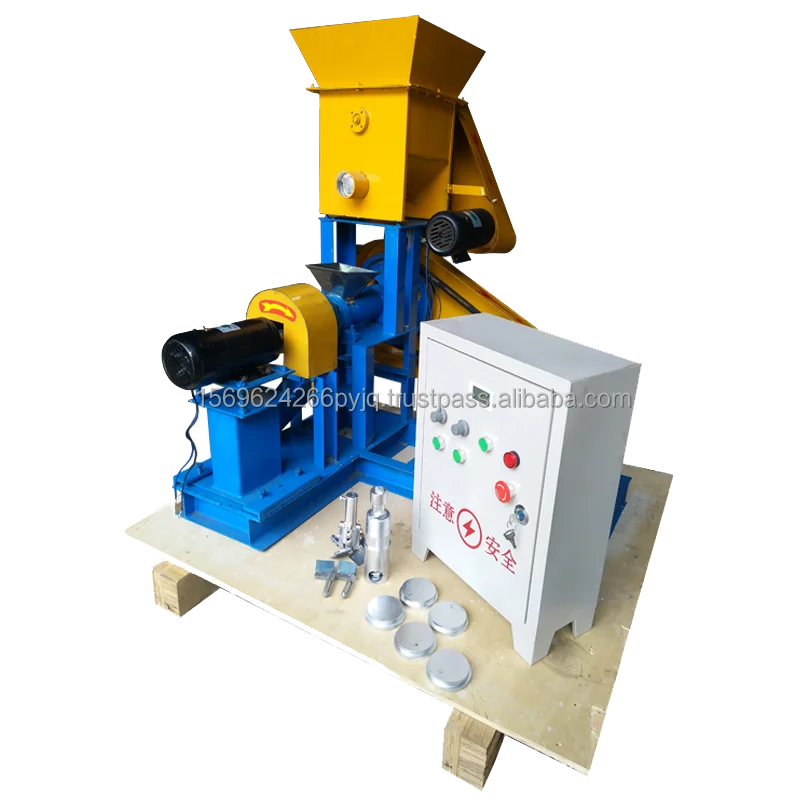

Puffing Snack Food Extruder Machine

Application:

This puffing snack food machine is used to make different kinds of puffed food snacks,the shapes can be customized.We can make many kinds shapes of final products,also accept customize.We will send 3 kinds of mould for free with our machines.

This puffing snack food machine is used to make different kinds of puffed food snacks,the shapes can be customized.We can make many kinds shapes of final products,also accept customize.We will send 3 kinds of mould for free with our machines.

FEATURES AT A GLANCE

Raw material can be :

Corn, rice,millets,wheat,oat,barley etc as ingredients.The effect will be much better if the materials in powder(flour) or grits

form.

Corn, rice,millets,wheat,oat,barley etc as ingredients.The effect will be much better if the materials in powder(flour) or grits

form.

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

Model | WSSH-40 | WSSH-50 | WSSH-60 | WSSH-70 | WSSH-80 |

Motor power | 4kw | 11kw | 15kw | 18.5kw | 22kw |

Output | 30-40kg/h | 60-100kg/h | 110-120kg/h | 150-180kg/h | 200kg/h |

Rotated speed | 500-600rp/min | 500-600rp/min | 440-550r/min | 440-550r/min | 440-550r/min |

Weight | 220kg | 280kg | 300kg | 420kg | 510kg |

Size | 1100*1080*1250mm | 1150*1100*1250mm | 1180*1120*1250mm | 1500*1400*1250mm | 1500*1450*1300mm |

PRODUCT CONFIGURATION

Working Principle of Snack Food Extruder Machine:

The working principle of a food puffing machine is to use a high-temperature and high-pressure environment to rapidly expand food ingredients in a short period of time, forming puffed food with a crispy texture. This device converts mechanical energy into thermal energy and uses the heat generated by the rotation of the machine to squeeze and cook food, thereby increasing its volume. The main working principle of a food puffing machine can be summarized as follows:

1.Conversion of mechanical energy into thermal energy: Food puffing machines generate heat through the rotation of the machine, which is used to extrude and heat food ingredients, causing them to rapidly expand in a short period of time.

2.High temperature and high pressure environment: By controlling the high temperature and high pressure environment, food raw materials undergo physical and chemical changes inside the extruder, thereby achieving the effect of expansion.

3.Forming puffed foods with a crispy texture: Foods that have undergone puffing treatment have a crispy texture because the gas inside the food rapidly expands under high temperature and pressure, making the structure of the food porous and crispy.

4.When selecting equipment, entrepreneurs need to consider factors such as production capacity, energy consumption, automation level, and adaptability. They should choose the appropriate puffing machine model based on the target market demand and product positioning to improve production efficiency, reduce costs, and stand out in market competition. In addition, optimization of production processes and quality control are also key factors in ensuring product quality

1.Conversion of mechanical energy into thermal energy: Food puffing machines generate heat through the rotation of the machine, which is used to extrude and heat food ingredients, causing them to rapidly expand in a short period of time.

2.High temperature and high pressure environment: By controlling the high temperature and high pressure environment, food raw materials undergo physical and chemical changes inside the extruder, thereby achieving the effect of expansion.

3.Forming puffed foods with a crispy texture: Foods that have undergone puffing treatment have a crispy texture because the gas inside the food rapidly expands under high temperature and pressure, making the structure of the food porous and crispy.

4.When selecting equipment, entrepreneurs need to consider factors such as production capacity, energy consumption, automation level, and adaptability. They should choose the appropriate puffing machine model based on the target market demand and product positioning to improve production efficiency, reduce costs, and stand out in market competition. In addition, optimization of production processes and quality control are also key factors in ensuring product quality

Structure of food puffing machine:

The food puffing machine mainly consists of a feeding system, a screw extrusion system, a heating system, and a cutting system.

1.The feeding system is responsible for feeding raw materials into the extruder through the feeding port. The raw materials can be in granular or powdered form.

2.The screw extrusion system is the core component of the extruder, ensuring uniform material transfer.

3.The heating system is used to heat materials and promote their expansion, and can be heated by electricity, steam, or other methods.

4.In some applications, the cutting system needs to cut the puffed material into the desired shape and size, so it may include a cutting device.

3.The heating system is used to heat materials and promote their expansion, and can be heated by electricity, steam, or other methods.

4.In some applications, the cutting system needs to cut the puffed material into the desired shape and size, so it may include a cutting device.

Successful Project

Project in Thailand

Project in India

Project in Russia

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

Q1:How about the guarantee?

A1:How to order?

How about the guarantee?

The food puffing machine produced by Lerford Machine has a 2-year warranty, but customers need to operate the machine correctly according to our instructions and maintain it regularly.

About The Service:

Pre-sale Service

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the client’s special requirement,offering the reasonable plan and free design helping to select the equipment

4) Welcome to visit our factory or the domestic clients’ factory

Services during the sales

1) Provide factory layout according to your factory size in advance

2) Inspect the machine before leaving the factory

3) Oversea installation and commissoning the equipment

4) Technician will work with your workers together and teach your workers how to install machines,how to operate machines,how to maintain machines during daily working

5) Provide English Version of installation/Operation/Service/Maintenance Manual

After sale services

1) Provide 1 year complete warranty and life-time maintenance service

2) Provide the spare parts at preferential price for an extended long time

3) Provide technical exchanging.

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the client’s special requirement,offering the reasonable plan and free design helping to select the equipment

4) Welcome to visit our factory or the domestic clients’ factory

Services during the sales

1) Provide factory layout according to your factory size in advance

2) Inspect the machine before leaving the factory

3) Oversea installation and commissoning the equipment

4) Technician will work with your workers together and teach your workers how to install machines,how to operate machines,how to maintain machines during daily working

5) Provide English Version of installation/Operation/Service/Maintenance Manual

After sale services

1) Provide 1 year complete warranty and life-time maintenance service

2) Provide the spare parts at preferential price for an extended long time

3) Provide technical exchanging.

How to make the order?

The purchasing process of a food puffing machine can be carried out through the following steps:

1.Determine requirements: Firstly, clarify your needs, such as whether you need a puffing machine specifically for raw materials such as rice, corn, sorghum, and yellow rice, or a multifunctional puffing machine that can handle multiple raw materials. Understanding this information will help you choose the appropriate machine.

2.Search and comparison: Search different food puffer suppliers through the Internet to compare their product characteristics, prices, technical parameters, etc. You can view puffing machines from brands such as Qufu Ruidong Machinery Manufacturing Factory and Jinan Langzheng Machinery, which offer a variety of models and functions to meet the needs of different users.

3.Contact supplier: Once you find a puffing machine that meets your needs, you can contact the supplier by phone, email, or online chat to inquire about detailed information such as machine specifications, prices, shipping methods, etc.

4.Order purchase: After confirming all details, you can complete the purchase through online payment or offline transfer. Remember to request purchase vouchers, such as invoices or receipts, for possible maintenance or warranty needs in the future.

5.Follow up services: Understand whether the supplier provides installation, debugging, training, and other services. Some suppliers may also provide warranty services for a certain period of time to ensure the normal operation and use of the machine.

6.By following the above steps, you can smoothly place an order to purchase a food puffing machine, ensuring that the purchased machine meets your needs and receives good service support during use.

1.Determine requirements: Firstly, clarify your needs, such as whether you need a puffing machine specifically for raw materials such as rice, corn, sorghum, and yellow rice, or a multifunctional puffing machine that can handle multiple raw materials. Understanding this information will help you choose the appropriate machine.

2.Search and comparison: Search different food puffer suppliers through the Internet to compare their product characteristics, prices, technical parameters, etc. You can view puffing machines from brands such as Qufu Ruidong Machinery Manufacturing Factory and Jinan Langzheng Machinery, which offer a variety of models and functions to meet the needs of different users.

3.Contact supplier: Once you find a puffing machine that meets your needs, you can contact the supplier by phone, email, or online chat to inquire about detailed information such as machine specifications, prices, shipping methods, etc.

4.Order purchase: After confirming all details, you can complete the purchase through online payment or offline transfer. Remember to request purchase vouchers, such as invoices or receipts, for possible maintenance or warranty needs in the future.

5.Follow up services: Understand whether the supplier provides installation, debugging, training, and other services. Some suppliers may also provide warranty services for a certain period of time to ensure the normal operation and use of the machine.

6.By following the above steps, you can smoothly place an order to purchase a food puffing machine, ensuring that the purchased machine meets your needs and receives good service support during use.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices