Laser Cutting and Sheet Metal Fabrication with AISI 304 Stainless Steel for Medical Devices

- Category: >>>

- Supplier: Shenzhen Rollyu Precision Machining Co. Ltd.

Share on (1601229660747):

Product Overview

Description

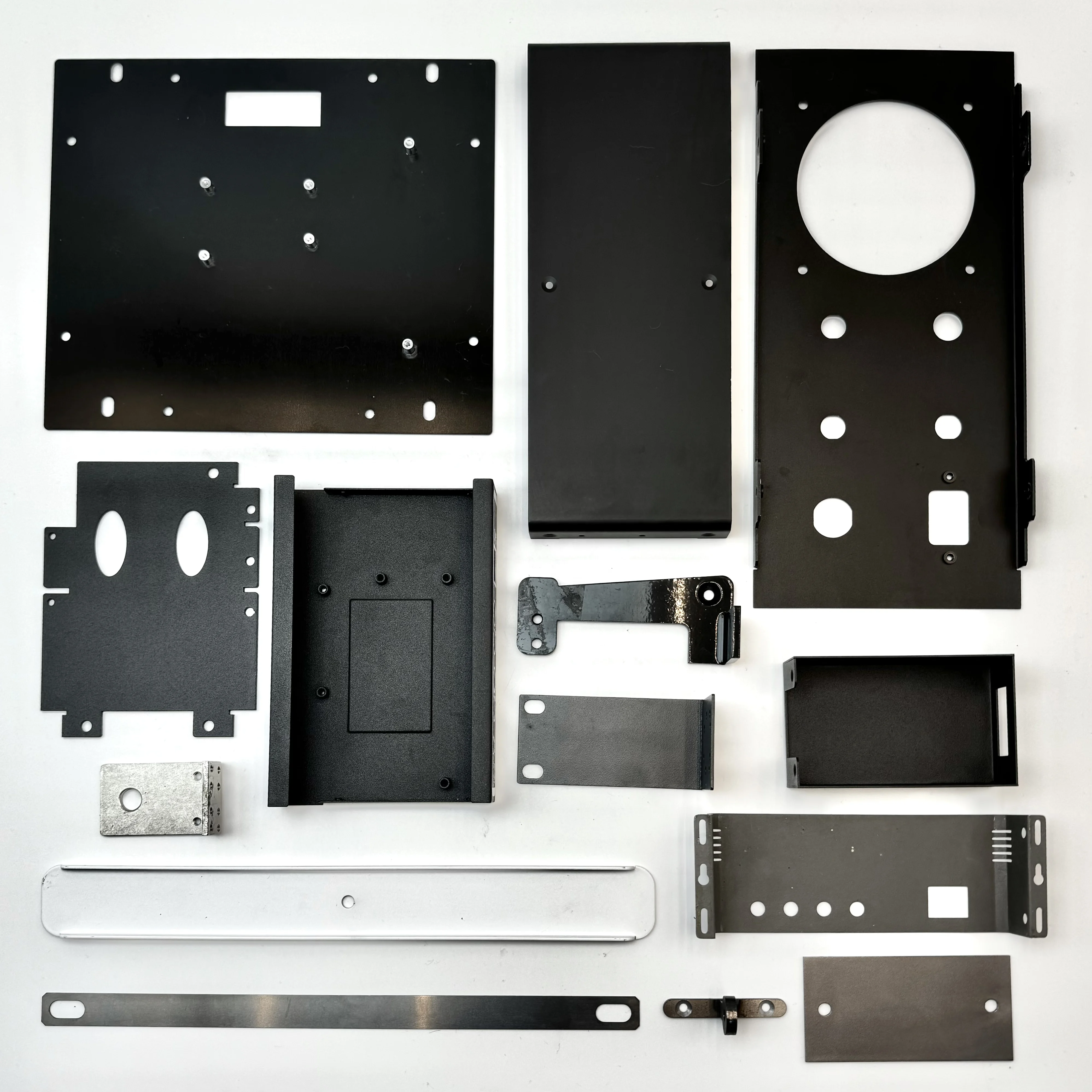

Title: Custom High Precision AISI 304 Stainless Steel Laser Cut Parts for Medical and Dental Industries

Overview: Elevate the sophistication of your industrial applications with our custom laser cutting service, specially designed for the medical and dental industries. Utilizing top-grade AISI 304 stainless steel, we offer precision-engineered components including metal brackets, clamping brackets, label tubing, and more, tailored exactly to your specifications.

Features:

* Material Excellence: We use AISI 304 stainless steel renowned for its corrosion resistance and durability, ensuring that our components meet the highest standards required for medical environments.

* High Precision Laser Cutting: Our state-of-the-art laser cutting technology enables us to achieve precision down to micrometer accuracy, suitable for the most demanding applications in medical and dental equipment manufacturing.

* Custom Fabrication: From conceptualization to final product, we tailor every part to fit your specific requirements. Whether it’s custom-sized clamping brackets or intricately designed metal parts, our products are designed to integrate seamlessly with your existing systems.

* Wide Application Scope: Ideal for a variety of uses within the medical and dental fields, including surgical instruments,

orthodontic devices, and customized dental equipment frameworks.

* Robust Quality Control: Each product undergoes rigorous testing and quality assurance processes to ensure performance and reliability under the stringent conditions of medical use.

Specifications:

* Material: AISI 304 Stainless Steel

* Cutting Accuracy: Up to ±0.005 mm

* Available Products: Laser cutting parts, clamping brackets, metal brackets, label tubing, etc.

* Industries Served: Medical, dental, instrumentation

Why Choose Us? Our facility is equipped with advanced laser-cutting machinery operated by skilled technicians who have extensive experience in handling complex designs and high-precision requirements. We collaborate closely with you to understand your needs and deliver exactly what you envision, ensuring each product is crafted with the utmost care and precision.

Ordering Information:

* Custom orders are welcome; please provide detailed drawings or specifications.

* Small to large batch production capabilities to suit your business scale and needs.

* Fast lead times and competitive pricing without compromising quality.

Contact Us: Start a conversation today to see how we can assist in developing and supplying top-tier stainless steel components for your specialized medical or dental equipment needs. We are here to provide comprehensive support and look forward to becoming your trusted partner in precision manufacturing.

Secure your supply of high-precision, stainless steel components tailored to the rigorous demands of the medical and dental industries by contacting us now!

Overview: Elevate the sophistication of your industrial applications with our custom laser cutting service, specially designed for the medical and dental industries. Utilizing top-grade AISI 304 stainless steel, we offer precision-engineered components including metal brackets, clamping brackets, label tubing, and more, tailored exactly to your specifications.

Features:

* Material Excellence: We use AISI 304 stainless steel renowned for its corrosion resistance and durability, ensuring that our components meet the highest standards required for medical environments.

* High Precision Laser Cutting: Our state-of-the-art laser cutting technology enables us to achieve precision down to micrometer accuracy, suitable for the most demanding applications in medical and dental equipment manufacturing.

* Custom Fabrication: From conceptualization to final product, we tailor every part to fit your specific requirements. Whether it’s custom-sized clamping brackets or intricately designed metal parts, our products are designed to integrate seamlessly with your existing systems.

* Wide Application Scope: Ideal for a variety of uses within the medical and dental fields, including surgical instruments,

orthodontic devices, and customized dental equipment frameworks.

* Robust Quality Control: Each product undergoes rigorous testing and quality assurance processes to ensure performance and reliability under the stringent conditions of medical use.

Specifications:

* Material: AISI 304 Stainless Steel

* Cutting Accuracy: Up to ±0.005 mm

* Available Products: Laser cutting parts, clamping brackets, metal brackets, label tubing, etc.

* Industries Served: Medical, dental, instrumentation

Why Choose Us? Our facility is equipped with advanced laser-cutting machinery operated by skilled technicians who have extensive experience in handling complex designs and high-precision requirements. We collaborate closely with you to understand your needs and deliver exactly what you envision, ensuring each product is crafted with the utmost care and precision.

Ordering Information:

* Custom orders are welcome; please provide detailed drawings or specifications.

* Small to large batch production capabilities to suit your business scale and needs.

* Fast lead times and competitive pricing without compromising quality.

Contact Us: Start a conversation today to see how we can assist in developing and supplying top-tier stainless steel components for your specialized medical or dental equipment needs. We are here to provide comprehensive support and look forward to becoming your trusted partner in precision manufacturing.

Secure your supply of high-precision, stainless steel components tailored to the rigorous demands of the medical and dental industries by contacting us now!

Shenzhen Rollyu Precision Machining Co., Ltd is an ISO 9001:2015 certified leading provider of high-precision CNC machining services, sheet metal fabrication, and die-casting parts for medical devices, oil and gas, automation, robotics, automotive, and aerospace industries. Since 2016, our relentless commitment to quality, precision, and innovation has positioned us as a trusted partner for organizations seeking reliable and efficient positioned us as a trusted partner for organizations seeking reliable and efficient mechanical components. With our state-of-the-art facilities and talented workforce, we specialize in custom manufacturing intricate parts that meet stringent industry standards and demanding customer requirements.

CAPABILITIES

Our comprehensive range of services includes multi-axis CNC milling, turning, grinding, wire EDM, gear hobbing, die-casting, sheet metal fabrication, finish services, and advanced inspection capabilities. By leveraging cutting-edge technology and equipment, such as 5-axis CNC machines, laser-cutting machines, and die-casting machines, we can produce complex geometric components with, tight tolerances and exceptional surface finishes. We work with a variety of materials, including titanium, stainless steel, aluminum, copper, brass, and an array of engineering plastics. The surface finish includes anodizing, passivation, black oxide, electroplating, polishing, heat treatment, powder coating, laser marking, silk-printing, oil spraying and so on.

QMS

Quality Management System (QMS) to ensure the highest level of quality and customer satisfaction. Our QMS incorporates ISO9001 certifications, ensuring strict adherence to global standards. Our sophisticated inspection processes utilize advanced metrology equipment, such as coordinate measuring machines (CMM), optical comparators, profile projectors, digital micro-dials, height gauges, ID &OD micrometers, thread gauges, hardness testers, and surface roughness testers, to verify that every part meets the specified requirements, we guarantee the highest levels of quality and traceability.

ENGINEERING EXPERTISE

Backed by a skilled team of engineers and machinists, we have the expertise to provide design-for-manufacturing support and seamless execution of complex projects. Our dedicated engineering staff collaborates with clients throughout each stage, from concept development to final product rigorous quality control processes ensure that every part meets the highest validation, to ensure the highest level of customer satisfaction.

CUSTOMER FOCUS

Customer Focus: Rollyu Precision Machining is committed to providing exceptional customer service and fostering long-lasting partnerships. Our experienced team works closely with clients to understand their unique needs, offering tailored solutions with fast turnaround times and competitive pricing. We also offer supply chain management services to streamline procurement, inventory management, and just-in-time delivery.

With our extensive experience, cutting-edge technology, and unwavering focus on quality, Rollyu Precision Machining has become a trusted partner for organizations in the medical device and aerospace sectors. We are proud to contribute to these industries' advancements by manufacturing essential components that facilitate improved health and safety, enhanced mobility, and next-generation innovations. Partner with us to ensure your project's success which includes engine components, structural elements, and avionic parts. By adhering to experience the difference in precision, performance, and partnership.

Frequently Asked Questions At Rollyu Precision

1. What materials do you use for sheet metal parts fabrication?

Answer: We utilize a variety of materials to meet the diverse needs of our clients, including but not limited to stainless steel, aluminum, copper, brass, and various alloys. Each material offers unique benefits, ranging from corrosion resistance to ease of machining.

2. Can you provide custom finishes on sheet metal parts?

Answer: Yes, we offer several finishing options to enhance the appearance and functionality of your parts. Options include powder coating, anodizing, painting, plating, silk printing, laser marking, and brushing. We can match any finish to your specific requirements for aesthetics or performance.

3. What are your capabilities concerning precision and tolerances in sheet metal fabrication?

Answer: Our state-of-the-art equipment allows us to work with precision up to ±0.005 inches. This capability ensures high

precision for complex designs and tight tolerances, necessary for many advanced applications.

4. How do you ensure the quality of your sheet metal parts?

Answer: Quality is our top priority. We employ rigorous quality control processes including material certifications, in-process inspections, and final visual and dimensional checks. Additionally, we are ISO 9001 certified, which underscores our commitment to maintaining the highest quality standards.

5. What is your lead time for producing custom sheet metal parts?

Answer: The lead time varies depending on the complexity and quantity of the parts. Typically, it ranges from 2 to 6 weeks. We offer expedited services for urgent projects, and we always work closely with you to meet your deadlines without compromising quality.

6. Are there any size limitations for the sheet metal parts you can fabricate?

Answer: We can fabricate sheet metal parts in sizes ranging from small, intricate components to large industrial pieces. Please contact us with specific dimensions, and our engineering team will review the feasibility based on our machinery capacity.

7. Can you assist with the design of custom sheet metal parts?

Answer: Absolutely! Our experienced engineering team can help refine your designs or create new ones from scratch. We use the latest CAD and CAM software and are happy to collaborate at any stage of the design process.

8. What is the minimum order quantity for sheet metal parts?

Answer: We strive to be flexible with order quantities and can handle everything from prototype fabrication to large-scale

production runs. We do not strictly enforce a minimum order quantity, but order volume can impact pricing.

9. What types of industries do you typically serve with your sheet metal parts?

Answer: We serve a diverse range of industries including aerospace, automotive, construction, electronics, and custom machinery among others. Our services are tailored to meet the stringent requirements and unique needs of each industry we work with.

10. How is pricing determined for custom sheet metal fabrication?

Answer: Pricing is based on several factors including material selection, production time, finish, and complexity of the part. We offer competitive pricing and provide detailed quotes to ensure transparency. To get a specific estimate, please send us your project details and we will provide a comprehensive pricing breakdown.

Answer: We utilize a variety of materials to meet the diverse needs of our clients, including but not limited to stainless steel, aluminum, copper, brass, and various alloys. Each material offers unique benefits, ranging from corrosion resistance to ease of machining.

2. Can you provide custom finishes on sheet metal parts?

Answer: Yes, we offer several finishing options to enhance the appearance and functionality of your parts. Options include powder coating, anodizing, painting, plating, silk printing, laser marking, and brushing. We can match any finish to your specific requirements for aesthetics or performance.

3. What are your capabilities concerning precision and tolerances in sheet metal fabrication?

Answer: Our state-of-the-art equipment allows us to work with precision up to ±0.005 inches. This capability ensures high

precision for complex designs and tight tolerances, necessary for many advanced applications.

4. How do you ensure the quality of your sheet metal parts?

Answer: Quality is our top priority. We employ rigorous quality control processes including material certifications, in-process inspections, and final visual and dimensional checks. Additionally, we are ISO 9001 certified, which underscores our commitment to maintaining the highest quality standards.

5. What is your lead time for producing custom sheet metal parts?

Answer: The lead time varies depending on the complexity and quantity of the parts. Typically, it ranges from 2 to 6 weeks. We offer expedited services for urgent projects, and we always work closely with you to meet your deadlines without compromising quality.

6. Are there any size limitations for the sheet metal parts you can fabricate?

Answer: We can fabricate sheet metal parts in sizes ranging from small, intricate components to large industrial pieces. Please contact us with specific dimensions, and our engineering team will review the feasibility based on our machinery capacity.

7. Can you assist with the design of custom sheet metal parts?

Answer: Absolutely! Our experienced engineering team can help refine your designs or create new ones from scratch. We use the latest CAD and CAM software and are happy to collaborate at any stage of the design process.

8. What is the minimum order quantity for sheet metal parts?

Answer: We strive to be flexible with order quantities and can handle everything from prototype fabrication to large-scale

production runs. We do not strictly enforce a minimum order quantity, but order volume can impact pricing.

9. What types of industries do you typically serve with your sheet metal parts?

Answer: We serve a diverse range of industries including aerospace, automotive, construction, electronics, and custom machinery among others. Our services are tailored to meet the stringent requirements and unique needs of each industry we work with.

10. How is pricing determined for custom sheet metal fabrication?

Answer: Pricing is based on several factors including material selection, production time, finish, and complexity of the part. We offer competitive pricing and provide detailed quotes to ensure transparency. To get a specific estimate, please send us your project details and we will provide a comprehensive pricing breakdown.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices