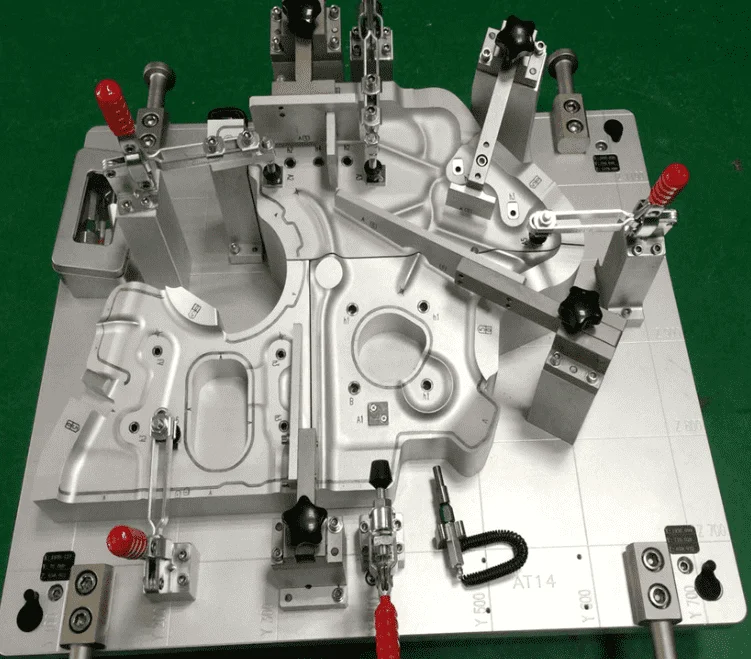

Design and customize automotive parts testing and inspection tools

- Category: >>>

- Supplier: Wuhan Shoujia Industrial Development Co. Ltd.Wuhan Ltd.

Share on (1601230019972):

Product Overview

Description

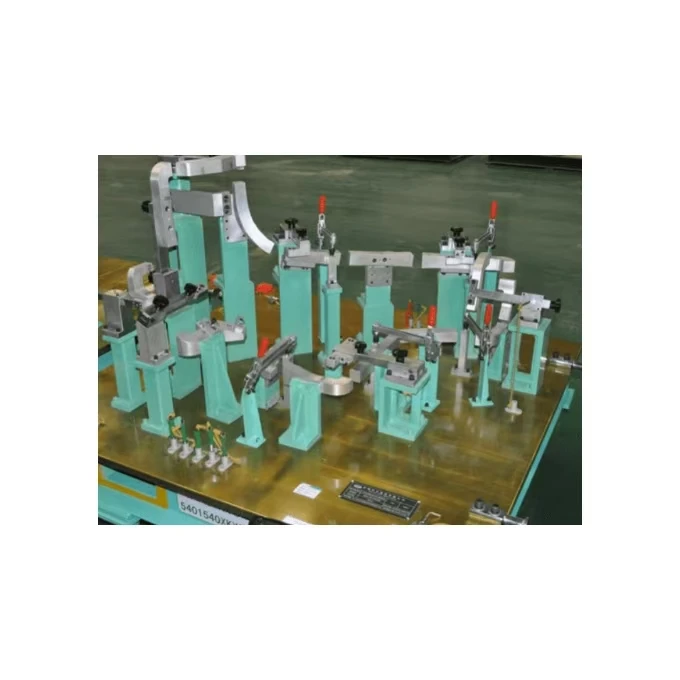

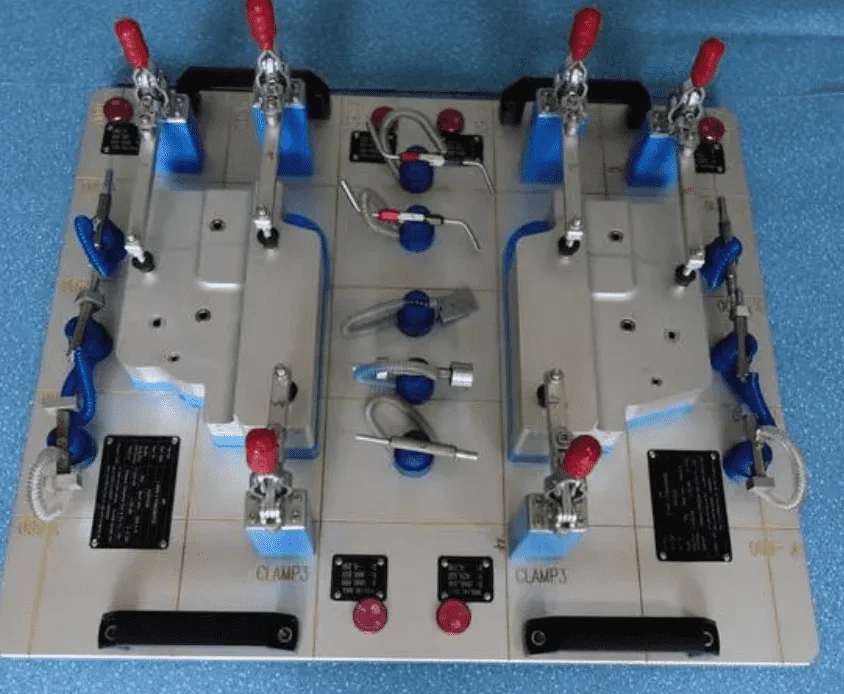

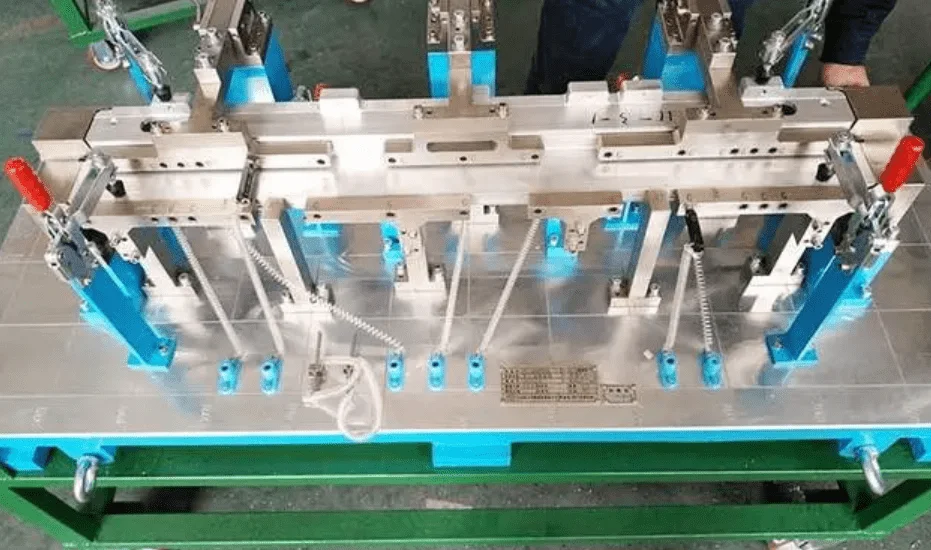

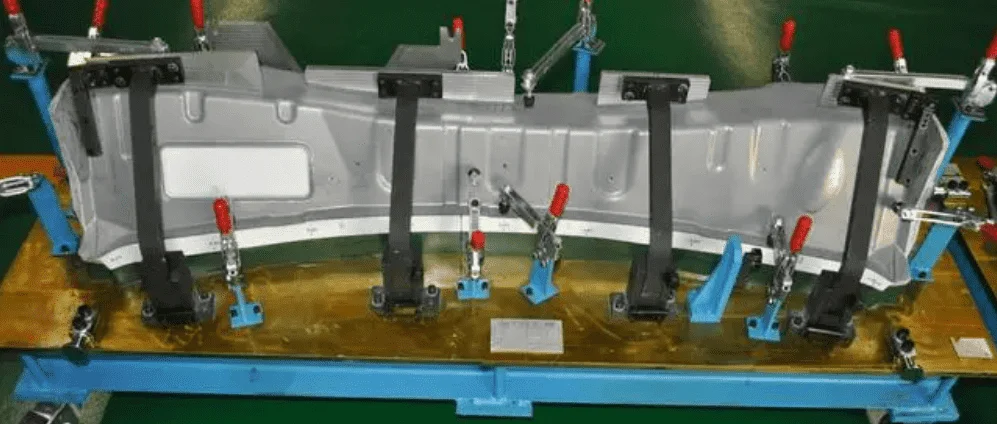

Product Name | Inspection tool |

material | mild steel |

color | silver grey |

shape | customized |

characteristic | Mechanical Inspection tool |

MQQ | 10 |

Q:What are molds, gauges, and frame products?

A : The molds, gauges, and frames for automotive metal structures are indispensable tools in the automotive manufacturing process, playing an important role in the production and quality control of automobiles.

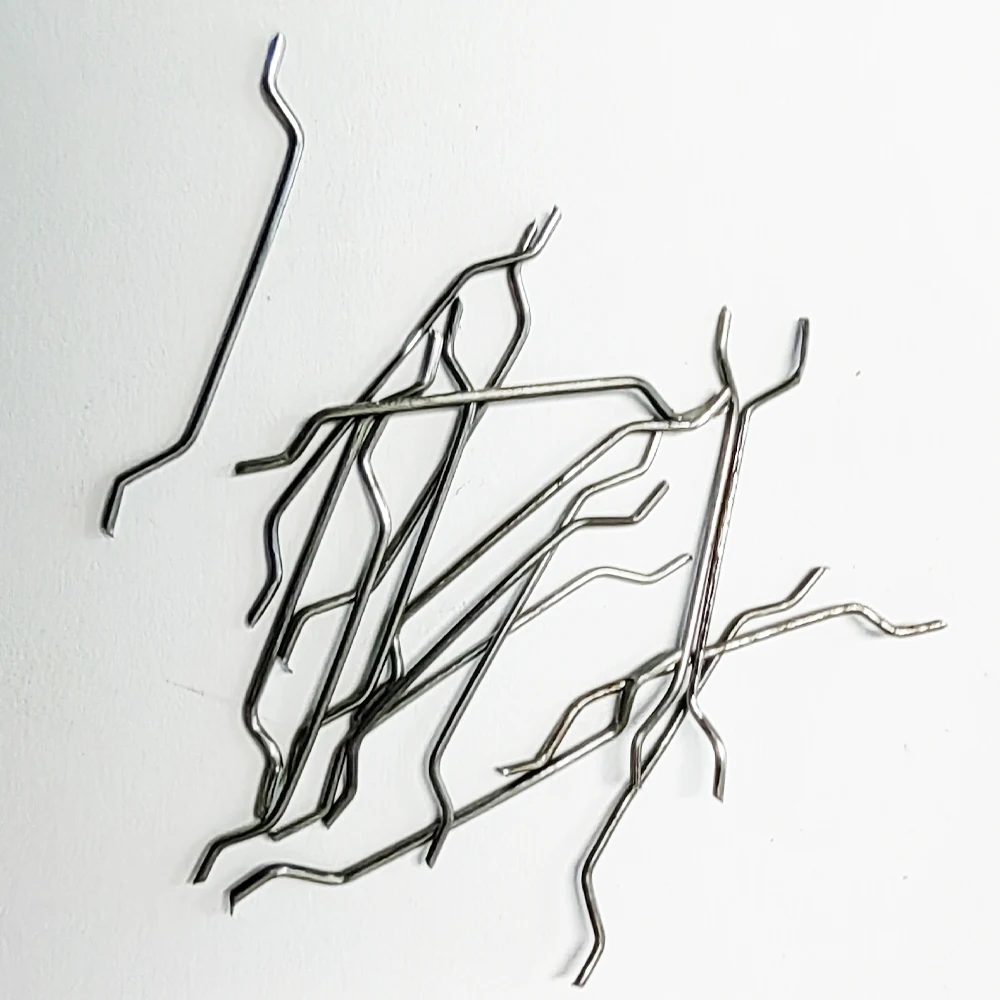

Mold: Mold is the foundation for manufacturing all parts of a car, especially the body parts. The production of molds is precise and complex, used for punching all stamping parts on automobile bodies, such as top cover flanging molds, crossbeam reinforcement plate pressing molds, etc. The general term for these molds is automotive molds, which are one of the most important tools in automotive production and directly determine the shape and structure of the car

Inspection tool: Inspection tools are mainly used to check whether the quality and size of automotive components meet the design requirements. In the process of automobile production, the role of gauges is to ensure that every produced component meets the design specifications, thereby ensuring the quality and performance of the entire vehicle.

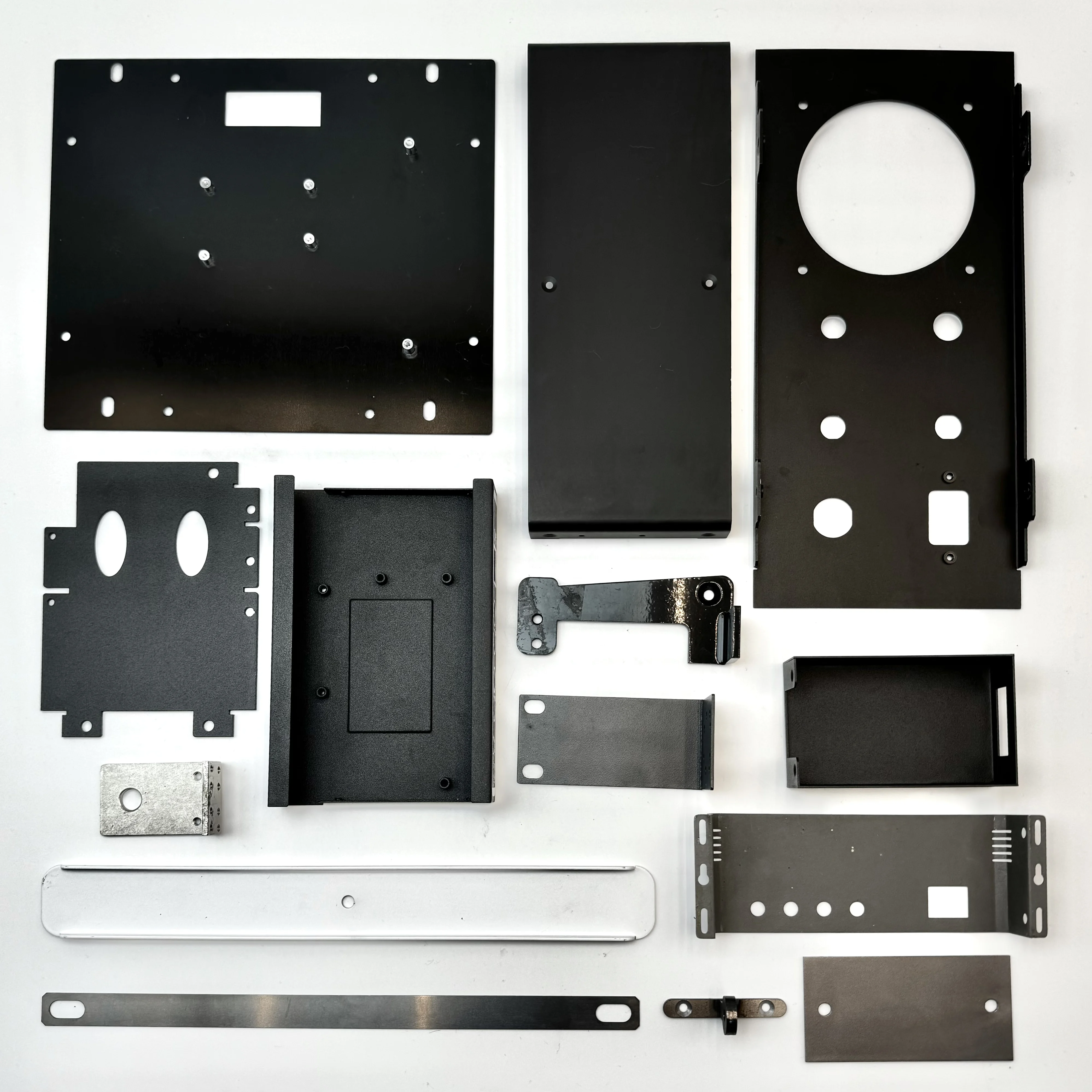

Frame: Frame is mainly used in automobile production to support and fix components, ensuring the correct position of components during production and assembly. The design and manufacturing of scaffolding need to take into account the complex structure of the car and the precise positioning of various components to ensure the overall structure and functionality of the car

A : The molds, gauges, and frames for automotive metal structures are indispensable tools in the automotive manufacturing process, playing an important role in the production and quality control of automobiles.

Mold: Mold is the foundation for manufacturing all parts of a car, especially the body parts. The production of molds is precise and complex, used for punching all stamping parts on automobile bodies, such as top cover flanging molds, crossbeam reinforcement plate pressing molds, etc. The general term for these molds is automotive molds, which are one of the most important tools in automotive production and directly determine the shape and structure of the car

Inspection tool: Inspection tools are mainly used to check whether the quality and size of automotive components meet the design requirements. In the process of automobile production, the role of gauges is to ensure that every produced component meets the design specifications, thereby ensuring the quality and performance of the entire vehicle.

Frame: Frame is mainly used in automobile production to support and fix components, ensuring the correct position of components during production and assembly. The design and manufacturing of scaffolding need to take into account the complex structure of the car and the precise positioning of various components to ensure the overall structure and functionality of the car

Q: Our equipment and production capacity?

A: Equipment tonnage 63T-2000T

The maximum area of the device platform is 5000 * 2500

Q: What is ISO9001?

A: ISO9001 is a globally recognized quality management system standard that provides a framework for various organizations to achieve success through improving customer satisfaction, enhancing employee motivation, and continuous improvement.

Q: What is IATF 16949:2016?

A: ATF 16949:2016 is a quality management system standard specifically designed for the automotive industry. It is based on the ISO 9001 standard, combined with specific requirements for the automotive industry such as QS9001, VDA6.1, EAQF, and AVSQ. This standard was developed by the International Automotive Task Force (IATF) with the aim of improving quality control and quality management in the automotive production process. The release of IATF 16949:2016 was in response to the requirements of ISO9001:2015 quality management system and was updated in 2016.

Q:What are OEM and ODM?

A: OEM (Original Equipment Manufacturer) refers to brand producers who do not directly produce products, but use their key core technologies to design and develop new products, control sales channels, and delegate specific processing tasks to other manufacturers through contract purchases.

ODM (Original Design Manufacturer) refers to a manufacturer who, after designing a certain product, may be noticed by other companies in certain situations, requiring them to use the latter's brand name for production or make slight modifications to the design for production.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices