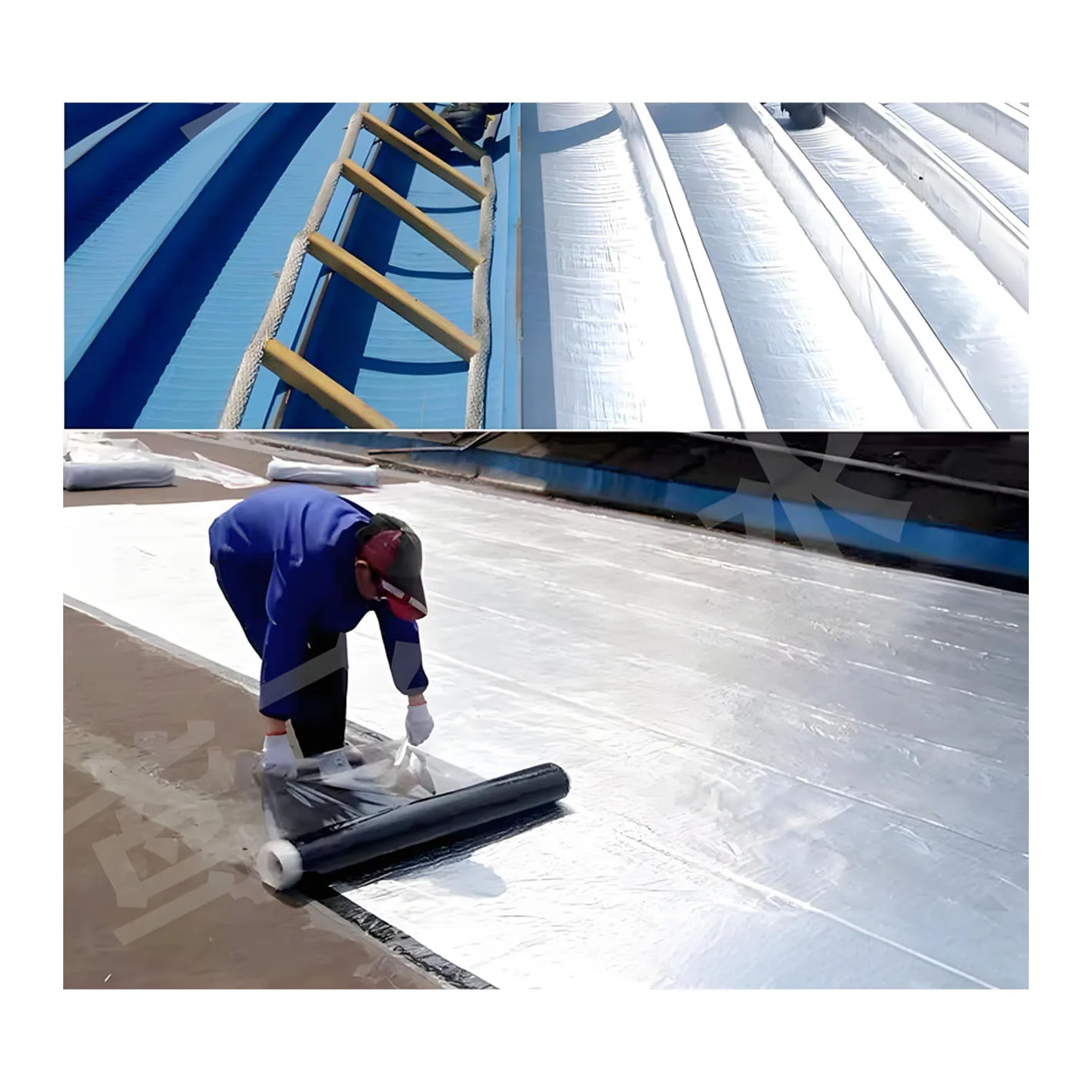

Epdm Rubber Roofing Waterproof Sheet Membrane Roll 3 8 Meters Wide

- Category: >>>

- Supplier: Qingdao Cairun Material Technology Co. Ltd.Qingdao Ltd.

Share on (1601231479472):

Product Overview

Description

ethylene propylene diene monomer (EPDM) rubber waterproof sheet membrane

Application:

1.mainly used in waterproof areas: roof,bridge,basement, toilet, underground, tunnel and dam,seal of alcohol in chemical industry.

2.Geo-synthetic liner for swimming pool, channels, irrigation system

3.Usually black, can be customized white, maximum reflection of light, forming a "cold roof"

choose us:

1.We are professional manufacturer of rubber and silicone products,270 workers, 40000 square meters non-dust workshop, over 17 years experience in the rubber industry.

2.While ensuring quality,we will give you the most appropriate price. no middleman.

3.Professional technical development team and production department.

4.Model and color can be totally customized

Feature:

Excellent anti-aging performance, service life up to 50 years

high extension rate, high tensile strength, small size changes at heat treatment

Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

Convenient application , solid joint, no environment pollution

chemical corrosion Resistance, can be used for special occasions

Convenient maitenance, low cost.

Convenient for dealing with details.

Good Anti-perforated

width 10 meters without joint

FAQ:

payment terms: T/T 30% deposit before producing, 70% balance before loading.

delivery time: within 7 days after deposit

How to get samples:We are pleased to offer you free samples.New clients are expected to pay for the sample freight,the cost will be deducted from the formal order

The packaging:

The packing is safety and waterproofing, which conforms with the export standard package;

or as your require

Products photo:

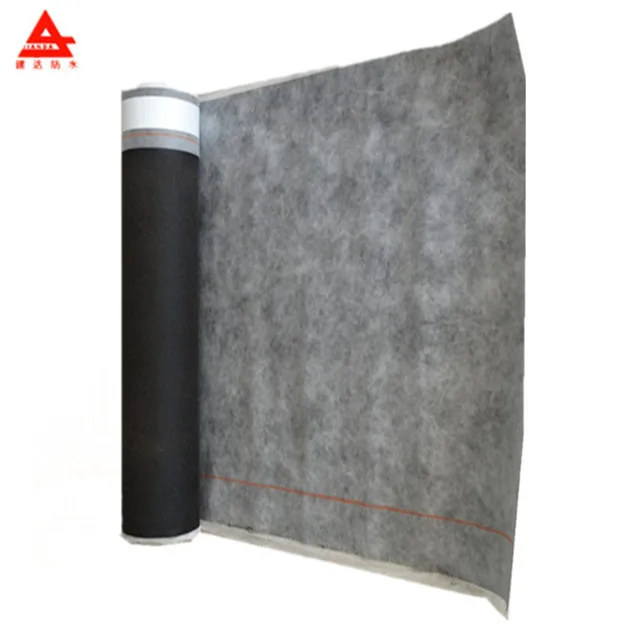

Epdm (OP) rubber waterproof membrane

Product Introduction

Epdm (OP)rubber waterproof membrane is a new type of high elasticity waterproof membrane that uses synthetic rubber, synthetic tire co-mixing system, adding reinforcement agent, softener, anti-aging agent, vulcanization promoter and other processing additives that are airtight and mixed, extruded, crushed and vulcanized, shaped and other processes.

Features

1.The special modified molecular structure effectively solves the deficiencies of ethylene propylene propylene glue joining at home and abroad;

2, long service life, anti-aging, roof materials can be used20More than years, can be reached Underground50The long time of the year;

3, high elongation, relatively high tensile strength, and small changes in heat treatment size;

4, it is resistant to plant roots and puncture, and can be used as a waterproof layer on the planting roof;

5The low temperature has good flexibility-35 No cracking, adapt to environmental temperature changes;

6, convenient construction, can be welded with hot air, firm and reliable construction, no environmental pollution;

Product types and specifications

Variety: homogenization, composite and internal enhancement

Thickness:1.2mm 1.5mm 2.0mm

Width:1-2m

Length:10-50m

Product Performance

Epdm (OP) rubber waterproof coiled material Performance Index

Item name

Indicators

Applicable test conditions

Tensile strength (N/cm)

Room temperature

7.5

GB6.3.2

60

2.3

Break the elongation rate%

Room temperature

450

20

200

Tear strengthN

N

25

GB6.3.3

Impermeability (0.3Mpa.30 min)

No leakage

GB6.3.4

Low temperature bending ( ) ≤

40

GB6.3.5

Heating telescopic amount (mm)

Extend ≤

2

GB6.3.6

Shrinkage ≤

4

Hot air aging

(80 168h)

Breaking tensile strength retention rate,%

80

GB6.3.7

Breaking the elongation retention rate,%

70

Alkaline resistant 10%Ca(OH)2

Room temperature 168h]

Breaking tensile strength retention rate,%

80

GB6.3.8

Breaking the elongation retention rate,%

80

Ozone aging (40 168h),200 10-8

GB6.3.9

Artificial atmosphere aging

Breaking tensile strength retention rate,%

80

GB6.3.10

Breaking the elongation retention rate,%

Breaking the elongation retention rate%

70

Adhesive peeling strength

(sheets and sheets)

N/mmStandard test conditions

1.5

GB6.3.11

Water immersion hold rate

(Room temperature 168h)%

70

Product application scope

It is applied to various anti-seepage and waterproof projects such as roofs, office buildings, large supermarkets, roofing of steel structure, basements, tunnels, bridges and so on of various types of industrial and civil buildings.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices