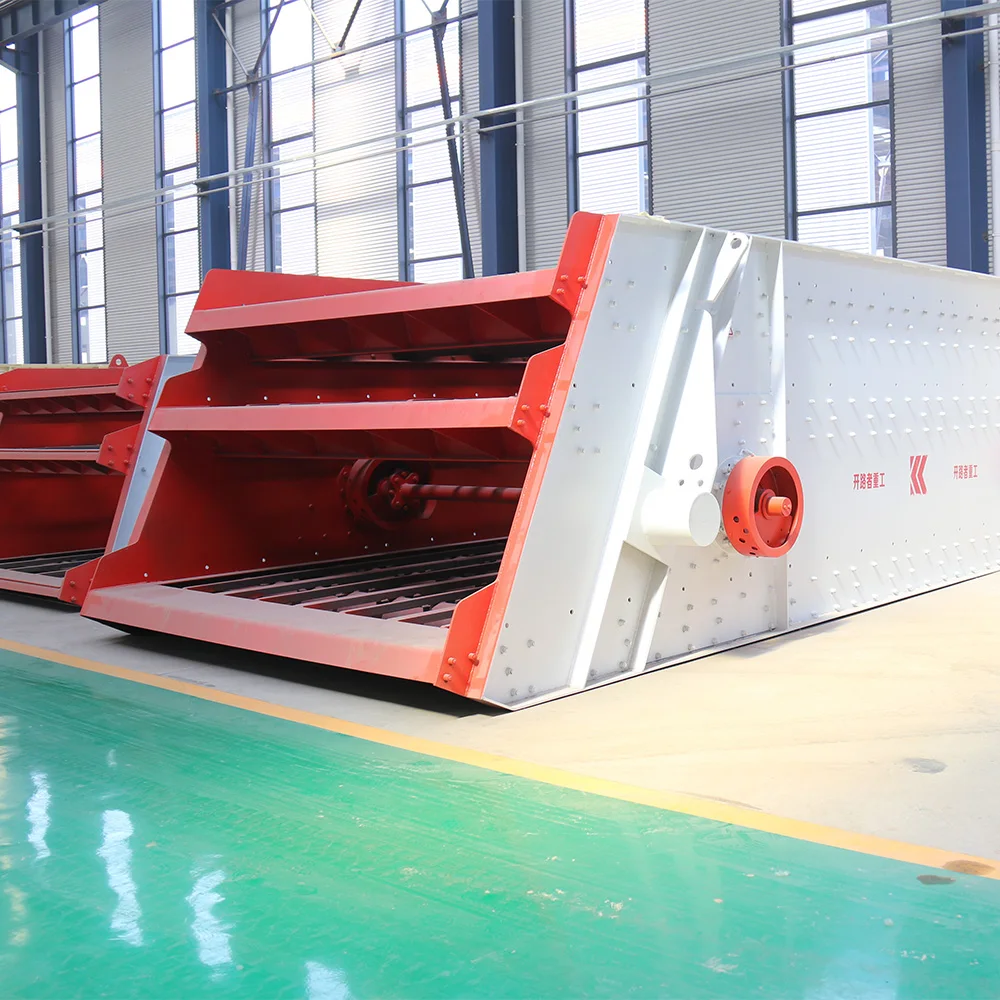

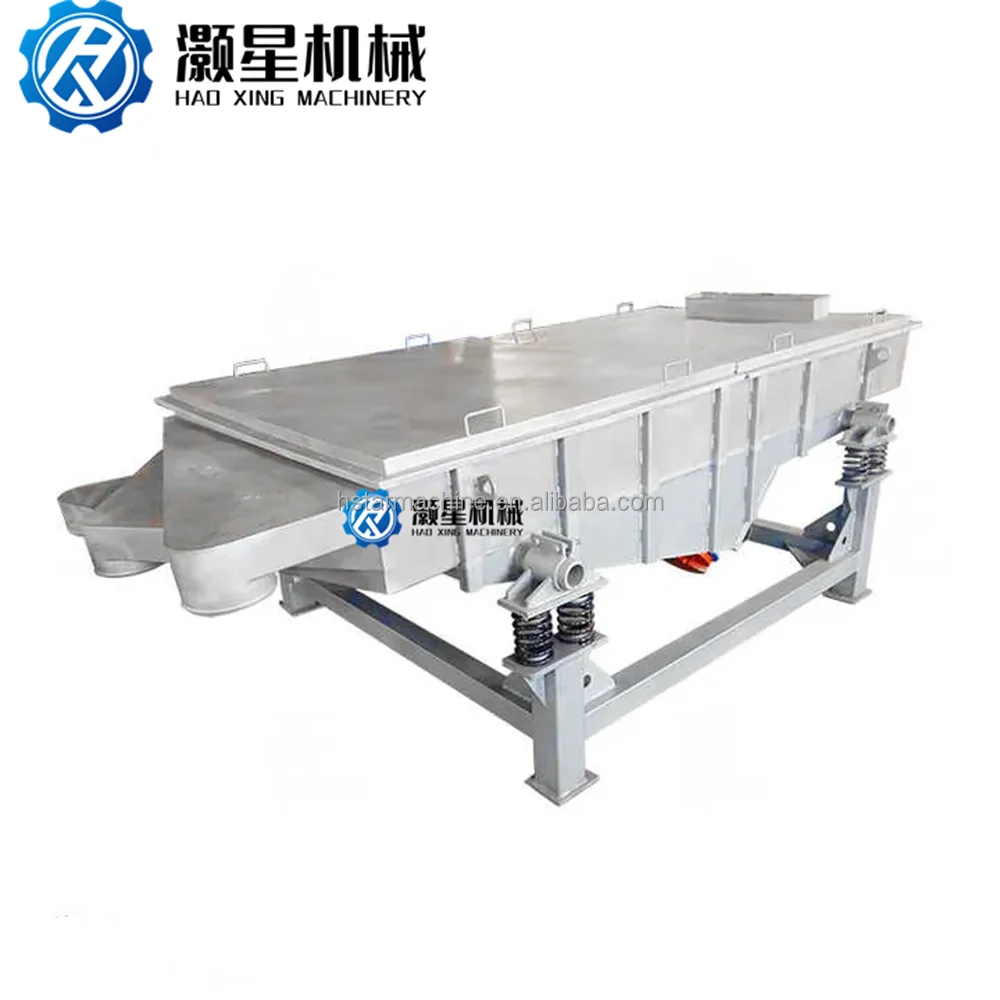

Broken Ore Vibration Screening Equipment Carborundum Sand Square Gyratory Sifter

- Category: >>>

- Supplier: Dayong Vibration Equipment Limited Liability Co

Share on (1601231487984):

Product Overview

Description

Broken Ore Vibration Screening Equipment Carborundum Sand Square Gyratory Sifter

Product Description

Product Introduction

Rectangular gyratory sifter adopts a fully enclosed structure, which is easy to install and control. The general design is 3 ~ 5 layers, and it can grade 4 ~ 6 sizes of materials in the same time. Users can install the number of screen layers as required.

Main Features

1. Whole sealing and no dust emission.

2. Low energy consumption,low noise and high efficiency.

3. High screening accuracy, large processing capacity and simple structure.

4. Firm and reliable, long service life.

5. It can be equipped with one or more layers of screen mesh.

6. The power layout can be adjusted to suit the production conditions according to the customer's needs.

2. Low energy consumption,low noise and high efficiency.

3. High screening accuracy, large processing capacity and simple structure.

4. Firm and reliable, long service life.

5. It can be equipped with one or more layers of screen mesh.

6. The power layout can be adjusted to suit the production conditions according to the customer's needs.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Using Scope

Stainless Steel Square Gyratory Vibrating Sieve is widely used in agriculture, food, medicine, mineral, chemistry, ceramics and other industries.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Specification

Model | Screen Size | Screen Area (m2) | Inclined Angle (°) | Layer (s) | Power (kw) | Allow Rotation Number | Screen Box Stroke (mm) |

DY-FY1536 | 1.5m*3.6m | 5.4-9 | 5.4±3 | 1-9 | 7.5 | 180-260 | 25-60 |

DY-FY2040 | 2m*4m | 8-9 | 5.4±3 | 1-9 | 15 | 180-260 | 25-60 |

Packing & Delivery

Company Profile

Xinxiang Dayong Vibration Equipment Co., Ltd. is a international manufacturing factory with research and development, design, production and sales services, it is committed to providing customers with reasonable and efficient screening, conveying and crushing equipment design solutions.

The company have more than 100 employers, and setted with R & D, technology and other departments, of which graduate students, college education accounted for more than 80%.

The company is located in Henan, Xinxiang province. The main products are divided into:

Fine screening equipment (lab sieve shaker; vibro screen; ultrasonic vibrating screen; flour screen; rotary sifter; liquid sifter; tumbler screener; linear vibrating screen; gyro screen, etc.);

Mining screen equipment (roller or trommel screen, circular vibrating screen; heavy linear vibrating screen; probability screen; dewatering sieve; stack sieve etc.)

Conveyor equipment (belt conveyor, screw conveyor, bucket elevator, etc.)

Crushing equipment (hammer crusher, jaw crusher, etc.)

The pruducts has passed the ISO9001 quality system and CE certification, and all the equipment fittings are famous brand in China.

The equipment is not only popular in China and have been exported to the United States; Australia; Russia; Britain; Spain; Germany; Japan; Holland; Poland; Turkey; Oman; Philippines; Thailand; Indonesia; Singapore and other countries and regions.

The company have more than 100 employers, and setted with R & D, technology and other departments, of which graduate students, college education accounted for more than 80%.

The company is located in Henan, Xinxiang province. The main products are divided into:

Fine screening equipment (lab sieve shaker; vibro screen; ultrasonic vibrating screen; flour screen; rotary sifter; liquid sifter; tumbler screener; linear vibrating screen; gyro screen, etc.);

Mining screen equipment (roller or trommel screen, circular vibrating screen; heavy linear vibrating screen; probability screen; dewatering sieve; stack sieve etc.)

Conveyor equipment (belt conveyor, screw conveyor, bucket elevator, etc.)

Crushing equipment (hammer crusher, jaw crusher, etc.)

The pruducts has passed the ISO9001 quality system and CE certification, and all the equipment fittings are famous brand in China.

The equipment is not only popular in China and have been exported to the United States; Australia; Russia; Britain; Spain; Germany; Japan; Holland; Poland; Turkey; Oman; Philippines; Thailand; Indonesia; Singapore and other countries and regions.

Customer Feedback

FAQ

Q: How to solve the problem of mixing materials?

A: Open the front door of the feed end to check the screen, re-tighten the flower nuts on both sides of the screen box.

Q:How to choose a suitable model for yourself?

1. what's the sieving material?

2. What's the material's density?

3. What's the capacity per hour of the gyratory vibrating screen you need ?

4. How many layers of the gyratory vibrating screen do you need?

5. What's the screen mesh size for each layer?

Please tell us the particle size distribution of the material more material property,such as the moisture, viscidity etc.

Q:Is it special requirement available?

A:Yes, the equipment could be designed according to customer's using aim or special requirements.

A: Open the front door of the feed end to check the screen, re-tighten the flower nuts on both sides of the screen box.

Q:How to choose a suitable model for yourself?

1. what's the sieving material?

2. What's the material's density?

3. What's the capacity per hour of the gyratory vibrating screen you need ?

4. How many layers of the gyratory vibrating screen do you need?

5. What's the screen mesh size for each layer?

Please tell us the particle size distribution of the material more material property,such as the moisture, viscidity etc.

Q:Is it special requirement available?

A:Yes, the equipment could be designed according to customer's using aim or special requirements.

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices