2 Ton Per Hour Feed Pellet Mill For Poultry Feed Pellet Production Line

- Category: >>>

- Supplier: MIKIM TECHNIQUE LLC

Share on (1601233397332):

Product Overview

Description

Products Description

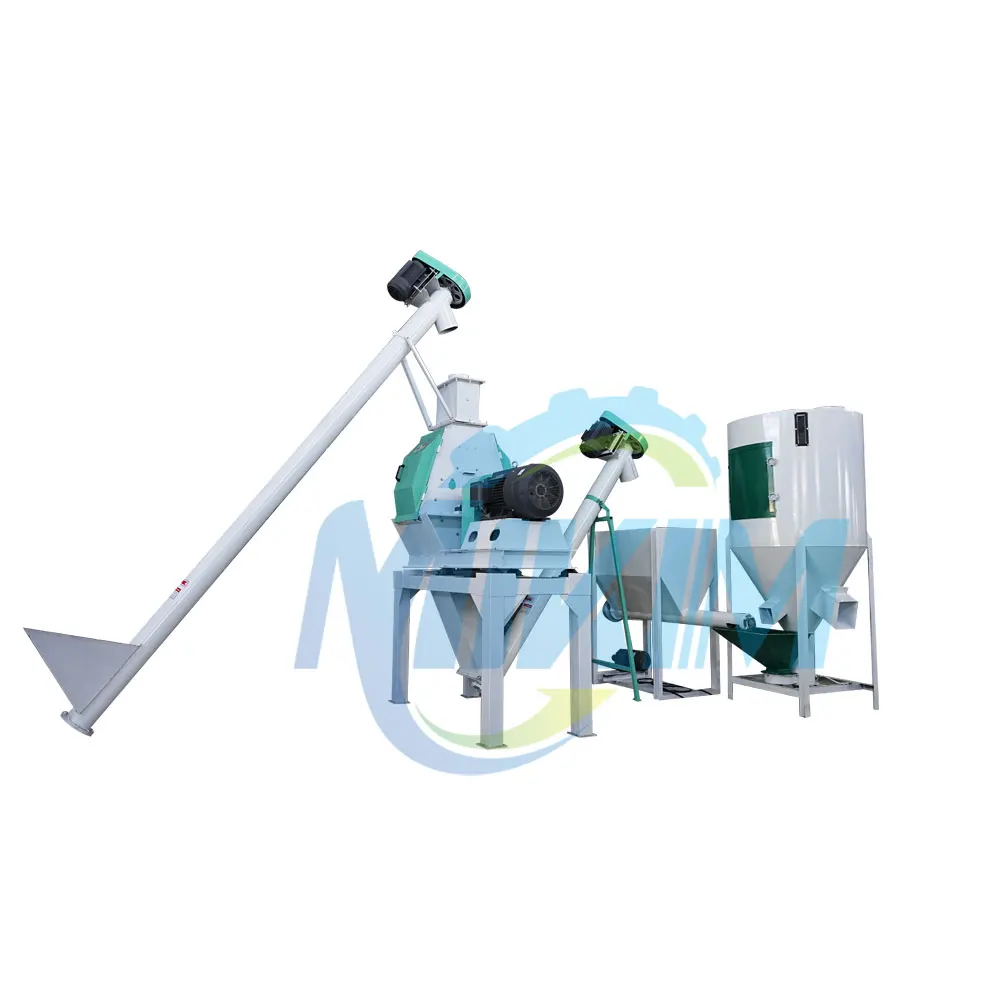

The 1-2 T/H Animal Feed Pellet Production Line produced by MIKIM Machinery has a small footprint, requires little electric power, and has low start-up costs. It is an ideal choice for newcomers to the feed production and processing industry. It covers everything from crushing and mixing of raw materials, to pelletizing, cooling and screening of feed pellets. There are even high-precision pellet packaging systems. It helps you produce high quality feed pellets at low cost.

Capacity | 1~2 Ton Per Hour |

Power(Kw) | 40~60 Kw |

Area(M2) | About 40 M2 |

High(M) | 5~11 M Customized |

Supported Feed Types | Livestock Feed, Poultry Feed, Sinking Fish and Shrimp Feed |

Supported Feed Size | 2~12 MM |

Supports Diversified Feed Formulations and Pellet Specifications:

This 1-2 T/H Animal Feed Pellet Production Line supports the production of various types of animal feed, such as livestock feed,such as cattle, sheep, horses, rabbits, camels, etc. poultry feed such as chicken, duck, geese, quail, etc. Through customization,it can also produce feed pellets containing grass such as Straw/Alfalfal for cattle, sheep and horses.

At the same time, different animals and different growth stages of animals have different pellet sizes suitable for feeding. For example, chicks need 2mm of broken feed, while laying hens need 4-5mm of feed, piglets need 3-3.5mm of feed, and growing pigs need 5-6mm of feed. Through customization, this 1-2 T/H Animal Feed Pellet Production Line can produce feed pellets of various specifications, which can expand your product types and increase market coverage.

This 1-2 T/H Animal Feed Pellet Production Line supports the production of various types of animal feed, such as livestock feed,such as cattle, sheep, horses, rabbits, camels, etc. poultry feed such as chicken, duck, geese, quail, etc. Through customization,it can also produce feed pellets containing grass such as Straw/Alfalfal for cattle, sheep and horses.

At the same time, different animals and different growth stages of animals have different pellet sizes suitable for feeding. For example, chicks need 2mm of broken feed, while laying hens need 4-5mm of feed, piglets need 3-3.5mm of feed, and growing pigs need 5-6mm of feed. Through customization, this 1-2 T/H Animal Feed Pellet Production Line can produce feed pellets of various specifications, which can expand your product types and increase market coverage.

Recommend Products

1, Grinding & Mixing Process.

Main Feed Machine: Raw Material Receiving Section → Grinding & Mixing Section.

2, Pelletizing Process.

Main Feed Machine: Bucket Elevator → Stock Bin → Pelletizing Section.

3, Cooling Process.

Main Feed Machine: Bucket Elevator → Cooling Section → Broken Section.

4, Packaging Process.

Main Feed Machine: Bucket Elevator → Screening Section → Packing Section.

Main Feed Machine: Raw Material Receiving Section → Grinding & Mixing Section.

2, Pelletizing Process.

Main Feed Machine: Bucket Elevator → Stock Bin → Pelletizing Section.

3, Cooling Process.

Main Feed Machine: Bucket Elevator → Cooling Section → Broken Section.

4, Packaging Process.

Main Feed Machine: Bucket Elevator → Screening Section → Packing Section.

Through the Hammer Mill, the granular raw material is crushed into very small granular. The hummer mill adopts a water drop shape and is equipped with a negative pressure air induction system, which improves the working efficiency of the hummer mill.

This Mixer is a single-shaft double ribbon mixer, suitable for mixing powdery materials and granular materials. It has high work efficiency and high mixing uniformity. A good mixer makes the composition of the feed pellets more uniform and the feed quality is higher.

Feed pellets are relatively hot and relatively soft just after pelleting. We can equip with cooler to reduce the temperature of pellets to room temperature to ensure the integrity of pellets.

MIKIM feed pellet mill is our main product. It can be used with flat or ring molds as required. It is also equipped with a conditioning agent that matures the raw material, making it more favorable for animal absorption and eliminating bacteria in the raw material.

The Automatic Packing System can used to package the final feed pellet. The qualified pellets are packed into plastic bag from 10

kg to 100 kg or 1 ton.Then use thermoplastic sealing machine to sew, these can make the pellets dry and water-proof. To extend the

feed pellets storage time.

kg to 100 kg or 1 ton.Then use thermoplastic sealing machine to sew, these can make the pellets dry and water-proof. To extend the

feed pellets storage time.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices