MD 1000 Pro limited on sale fast 1000*1000*1000mm full scale life size car plastic portable car battery chargers 3d printer

- Category: >>>

- Supplier: Shenzhen Mingda Technology Co. Ltd.Shenzhen Ltd.

Share on (1601236121593):

Product Overview

Description

Continuous Innovation, High Quality INDUSTRIAL 3D PRINTER

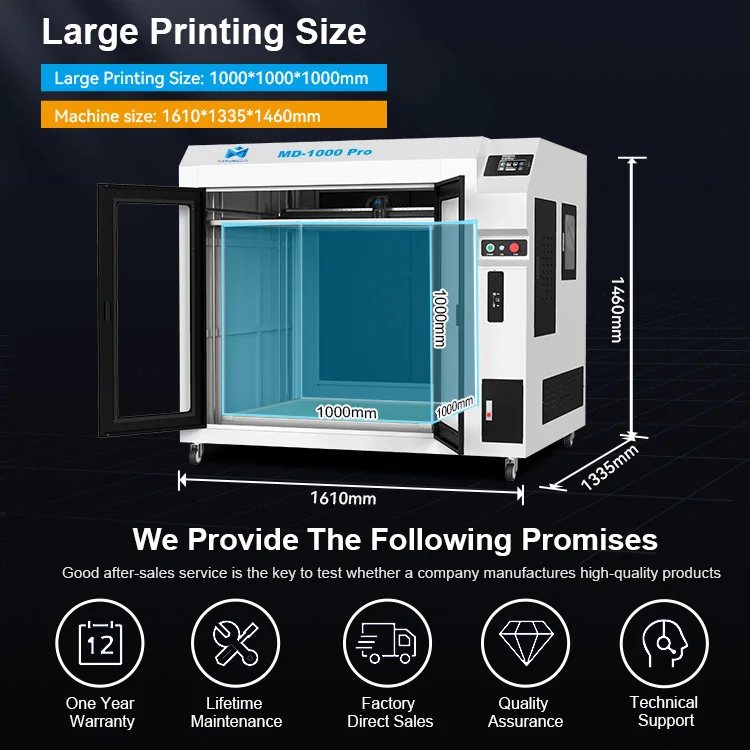

With a 1 cubic meter build volume, the MINGDA PRO is a fully enclosed industrial 3D printer for producing fullscale, large parts including functional prototypes, factory tooling, patterns and molds, and end-use parts. Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

Supported In its XY axis module structure, high precision and fast speed; Z axis four-screw, smooth and stable, MD-1000 Pro consistently provides speed, precision and quality. A new MINGDA hybrid hardware and software solution that lets you skip the hassle and start printing, the MD-1000Pro is easier than ever to use.

Details Images

Product Parameters

Printing | ||||

Model Name | ||||

Build Volume | 1000x1000x1000mm | |||

Weight | N.W.380KG/ G.W. 480KG | |||

Machine Size | 1612*1332*1465mm | |||

Print Technology | Fused Deposition Modeling | |||

Number of Nozzle | Single | |||

Layer Resolution | 0.05 mm-0.3mm | |||

Filament Diameter | 1.75 mm | |||

Filament Compatibility | PA12 PA-CF PA-GF PET-CF PET-GF Ht-ABS PETG-ESD Nylon PLA TPU etc. | |||

Nozzle Diameter | 0.4mm ( 0.6, 0.8, 1.0mm) | |||

Sample | ||||

Temperature | ||||

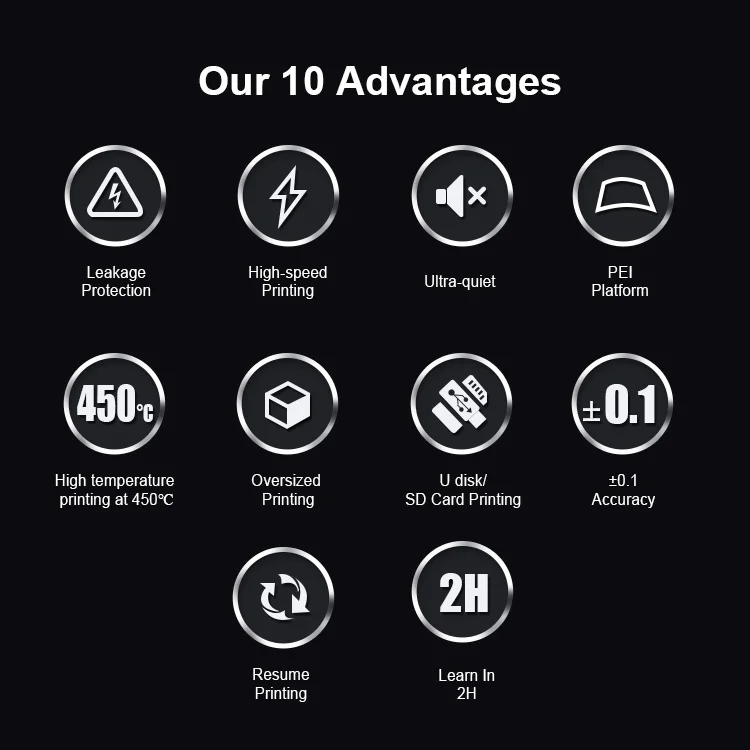

Max. Nozzle Temp. | 450℃ | |||

Max. Bed Temp. | 110℃ | |||

Speed | ||||

Best Printing Speed | 90mm/s-150mm/s | 150-200mm/s | ||

Max Printing Speed | 200mm/s | 200mm/s+ | ||

Platform | 10mm thickness aluminum hot bed | |||

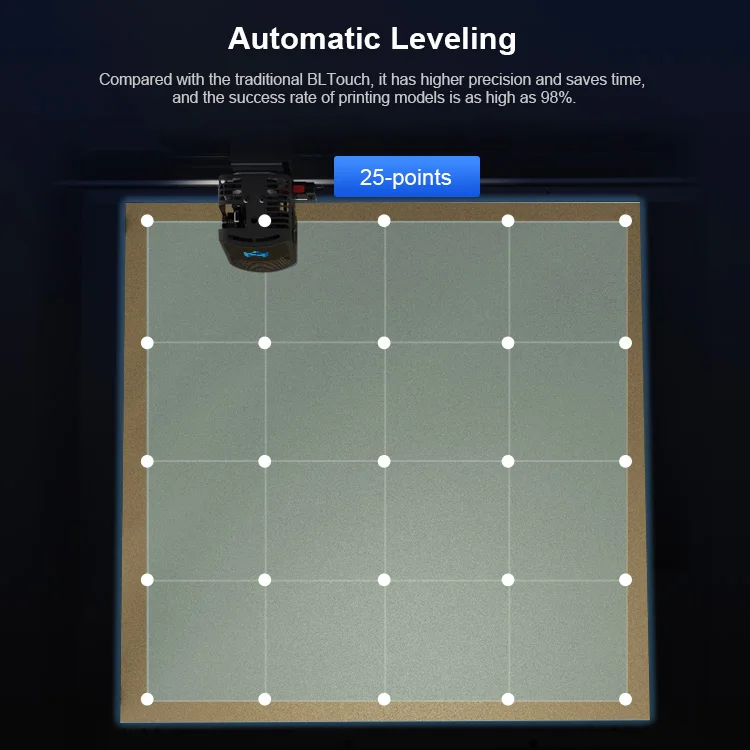

Levelling | Auto Leveling and Babystep | |||

Eletrical | ||||

Power Requirements | 110V/220V | |||

Max. Power | 780W | |||

Screen | 5.0 inch Color Touch Screen | |||

Connectivity | USB,SD card | |||

Software | ||||

Uninterruptible Power System | Save data when power is off | |||

Filament Detection | Pause printing when filament run out | |||

Automatic Shutdown | Turn off the power automatically when printing is complete | |||

Application Situation

PROTOTYPES

● Produce full-scale, functional parts from the alpha phase to zero series

● Learn faster and iterate designs in hours and days, not weeks and months

● Avoid expensive, outsourced, and traditional slow production

● Learn faster and iterate designs in hours and days, not weeks and months

● Avoid expensive, outsourced, and traditional slow production

TOOLING, JIGS, FIXTURES

● Customize tools for perfect fit, reduced weight, and ergonomic design● Slash lead times with on-demand production and avoid outsourcing logistics

● Reduce production and material costs of optimized tooling

PATTERNS AND MOLDS

● Replace high-cost patterns and molds made from expensive materials● Speed up design iteration, product testing, and production

● Minimize outsourcing, external logistics, and supply chain dependence

END-USE PARTS

● From small-series production to unique parts without added costs● Produce on-demand to reduce inventory and warehousing

● Reduce lead times and get to market fast to stay ahead of the competition

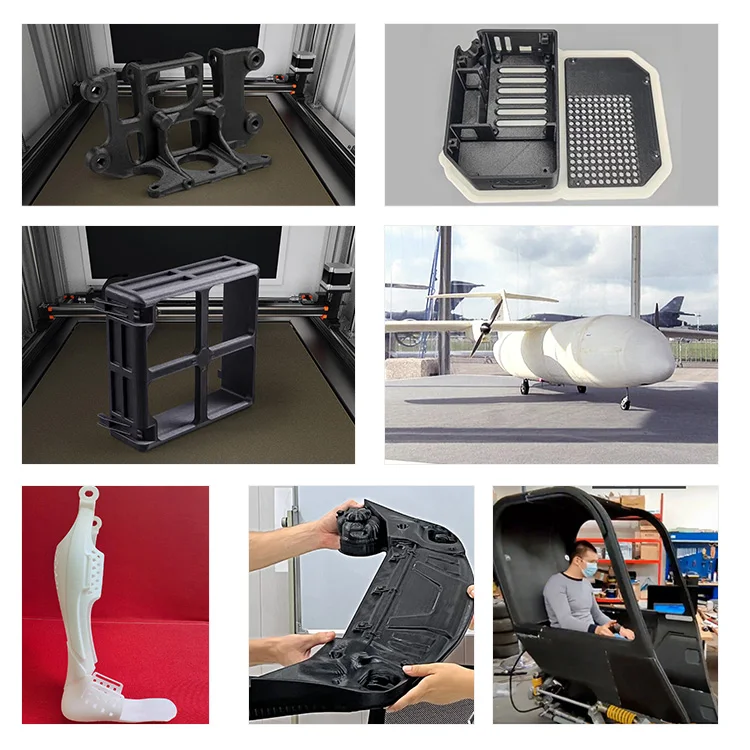

Customer model display

The following are customer case studies in the different industry, including aircraft design, automotive

design,portrait design,shoes design,automotive modification,architectural model,seat design,factory jig etc. If you want to get more information, send inquiry at the upper right !

Clients' Feedback

Here are some feedback and reviews from customers. I would like to showcase all of them if possible, but the space is limited. If you want to see more,send inquiry at the upper right !

Inventory and delivery display.

At present, we have enough inventory of MD-600 Pro to support fast delivery. Before placing an order, remember to contact my product consultant, because we sometimes have preferential prices.If you want to know more preferential prices ,send inquiry at the upper right !

Online&Offline Technical Training

We have a complete online and offline training system. The training content includes software and equipment training. When your goods arrive at your home, we will have technical contacts with you.If you want to know more,Send inquiry at the upper right !

Regarding after-sales service

Explanation of the after-sales service system for industrial 3D printers

1. Before you receive the product, we will send you an email to inform you of the precautions.

2. After you receive the machine:Email,instant message to follow up with you and train you on how to use the machine.

3. While you are using the machine, the

2. After you receive the machine:Email,instant message to follow up with you and train you on how to use the machine.

3. While you are using the machine, the

professional training team will reply to you within 24 hours and solve the problem within 3 days.

4. Visit customers regularly to check on usage status.

5. 3D printers usually have a one-year quality warranty, printhead parts have a three-month warranty, tools and PEI plates are not warranted.

4. Visit customers regularly to check on usage status.

5. 3D printers usually have a one-year quality warranty, printhead parts have a three-month warranty, tools and PEI plates are not warranted.

About our company

If you want to know more about cooperation matters, please send an inquiry at the upper right corner. Our professional team will answer your questions.

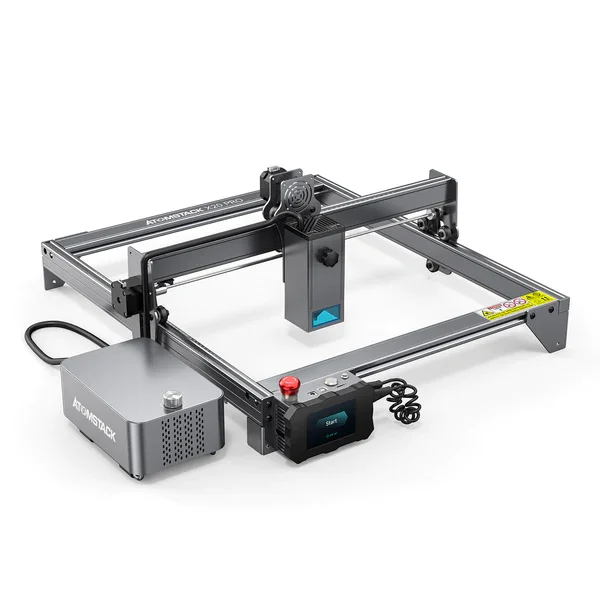

We Recommend

New Arrivals

New products from manufacturers at wholesale prices