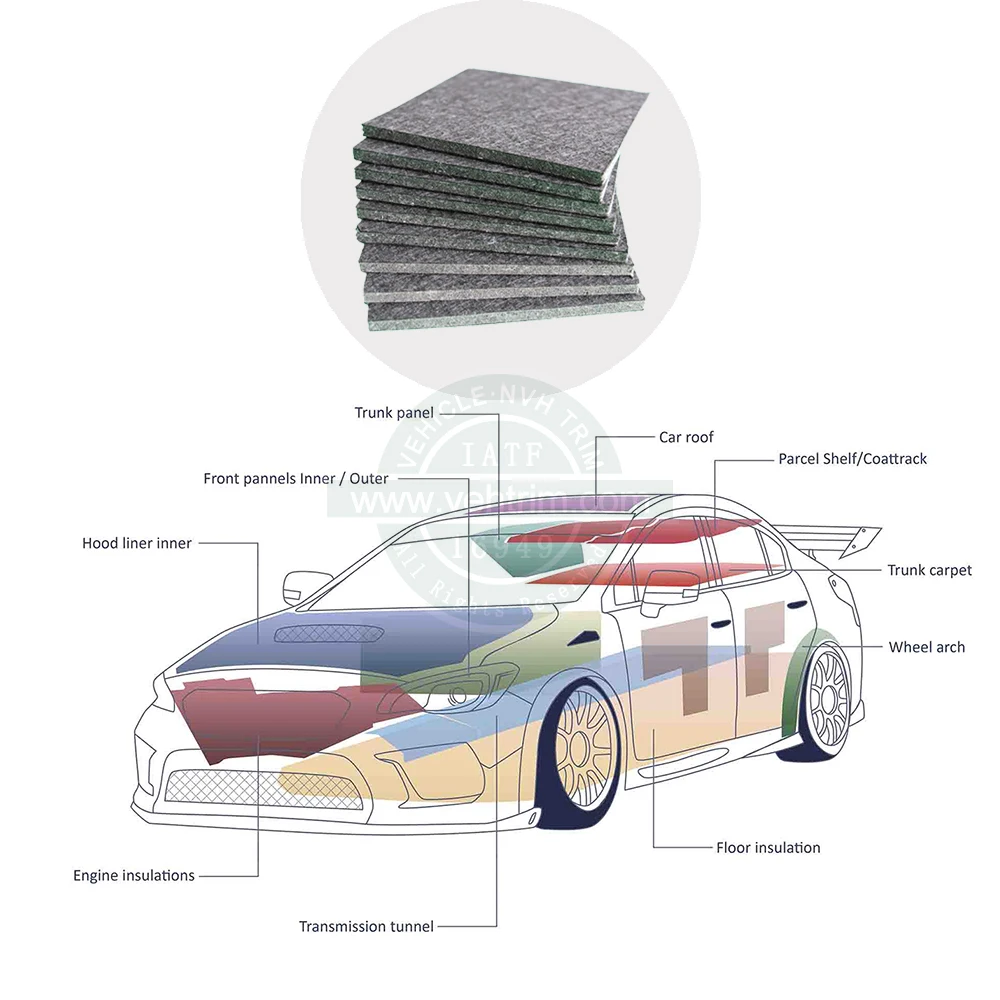

Best Felt car Insulation Car Sound Deadening Felt Glass Fiber Sheet For Chassis Protect Panel

- Category: >>>

- Supplier: Hainan Jinpeng Auto Trim Co. Ltd.

Share on (1601236182129):

Product Overview

Description

Products Description

Desc | Production | Recommend | Processing | Applications | Cases |

Nonwoven + PP Fiberglass + Nonwoven | Carding Web + Oven Combined Shaping | GSM: 1200-1800 g/㎡ Nonwoven 100 g/㎡ + PP Fiberglass + Nonwoven 100 g/㎡ | Moulded after Heating | Chassis Protect Panel, Parcel Shelf Body, Trunk Trim Panel, … | Chassis Protect Panel of HongQi E001, HongQi HS5, Geely SX11, … |

Samples | 3-5 days for stocked samples |

Production | Usually in 7-30 days, depending on order quantity |

Packing | Pallets, PE Film, PP Bag, Woven Bag, Carton Box or Customized |

Supply | Make-to-Order, OEM & ODM Available |

Origin | Hebei, China |

DownLoad | Contact us for E-catalog, DataSheet, etc. |

Note | We are B2B wholesale type and most of the Felt Products are customized, so we can't list all the specifications and styles, please just contact us for more details. |

Production Process

NVH Trim Materials Sumary

No. | Materials | Desc | Production | Recommend | Processing | Applications |

1 | LWRT / GMT / GPF | Nonwoven + PP Fiberglass + Nonwoven | Carding Web | GSM: 1200-1800 g/㎡ | Moulded after Heating | Chassis Protect Panel, Parcel Shelf Body, … |

2 | POE / EPDM / TPE / EVA | POE Granules + Calcium Powder | Heating Extrusion | Thick: 1-5 mm | Moulded after Heating | Insulator of Dashinner, Tunnel, Carpet Pad … |

3 | PET Nonwoven Microfiber Felt | Microfiber + PET Fiber + Low Melting Fiber | Carding Web | GSM: 300-1500 g/㎡ Microfiber: 0.5d-2.5d | Die-Cutting, Moulded after Heating | Dashinner, Roof, Door … |

PET Nonwoven Fiber Felt | PET Fiber + Low Melting Fiber | Carding Web | GSM: 200-3500 g/㎡ Fiber: 4d-16d | Die-Cutting, Moulded after Heating | Carpet Pad, Dashinner, NVH Acoustic Pack, Roof, Door ... | |

4 | PET Needling Felt | PET fiber + Low Melting Fiber / PP Fiber | Needle Punched | GSM: 500-1800 g/㎡ Minimum: 150g /㎡ | Die-Cutting, Moulded after Heating | Wheel House Cover and Other Hard Layer Felt |

5 | Semi Cured Resin Felt | Recycled Cotton Fiber + Phenolic Resin Powder | Air Laid | Thick: 15-25 mm GSM: 800-1400 g/㎡ | Moulding | Engine Compartment Insulator |

6 | Recycled Cotton Felt | Low Melting Fiber + Recycled Cotton Fiber + PET Fiber | Air Laid | PET Soft Cotton Felt Thick: 8-60 mm GSM: 300-3500 g/㎡ | Die-Cutting, Moulded after Heating | Insulation of Roof, Carpet Pad, Dashinner, Door Panel, Trunk Trim and Pad ... |

Carding Web | PET Hard Cotton Felt Thick: 5-12 mm GSM: 800-2000 g/㎡ | Die-Cutting, Moulded after Heating | Insulation of Dashinner, Wheel House Inner Cover, ... | |||

7 | V-lap 3D Cotton Felt | PET Fiber + Low Melting Fiber | Vertical Laying | GSM: 800-2500 g/㎡ | Die-Cutting, Moulded after Heating | Carpet Padding, Dashinner, Roof, Door Panel Space, NVH Acoustic Pack ... |

8 | Combined Sandwich Felt | PP Fiber + PET Fiber + GF Fiber + PE Film | Carding Web + Laminating | GSM: 800-1800 g/㎡ | Moulded after Heating | Wheel House Outer Assembly |

PP GF Felt + Gigging PET Carpet | Carding Web + Laminating | GSM: 800-1800 g/㎡ | Moulded after Heating | Trunk Trim System, Gate Trim Panel ... |

Material Production Lines

No. | Production Lines | Function | Capability | Qty | Workshop |

1 | Extrusion Line | Production | Max Width: 2200 mm Thickness: 1-5 mm | 1 | Laminating Workshop |

2 | Extrusion Laminating Machine (Lamination) | Production | Max Width: 2000 mm | 1 | Laminating Workshop |

3 | Non-woven PET Felt Line - 1, 2 | Air Laying Carding | Max Width - Air Laid: 2500 mm Max Width - Carding: 2700 mm | 2 | NonWoven Workshop |

Web and Shaping | Soft Cotton Felt: Thick:8-60 mm GSM:200-3500 g/㎡ Hard Cotton Felt: Thick:5-12 mm GSM:800-2000 g/㎡ | ||||

4 | Non-woven PET Felt Line - 3, 4, 5, 6 | Carding | Max Width: 2600 mm GSM:100-3500 g/㎡ | 4 | NonWoven Workshop |

Needle Punching | Max Width: 2800 mm GSM: 100-1800 g/㎡ |

Apps

Trunk Lid

Chassis Protect Panel

Wheel House Outer Cover

Wheel House Inner Cover

Engine Compartment Insulator

Carpet Assembly and Pad

Tunnel Insulator

Parcel Shelf

Trunk Carpet

Dashinner Insulation Pad

Trunk Side Lid

Trunk Storage

Space Acoustic Pack

Motor Cover

Seats Ventilation Panel

AC Compressor Sound Blanke

Processing Methods Summary

Work | No. | Processing Methods | Introduction | Equipment |

Materials processed to Finished Parts | 1 | Die-Cutting | Products are only flat, do not require molding | Rolling / Punching cutting machine |

2 | Laminating | Coat the back of the material with PE film | Laminating Machine | |

3 | Moulding - Heats Mold | Heating the Mold through an oil temp machine, Room temperature material | Hydraulic Machine | |

4 | Oil Temp Machine | |||

5 | Moulding - Heats Material | Oven Heats Materials, Mold the softened material | Hydraulic Machine | |

6 | Oven | |||

7 | Moulding - Heats Material | Platform Heats Materials, Mold the softened material | Hydraulic Machine | |

8 | Heating Platform | |||

9 | Thermal Bonding | Materials are thermally bonded together, through high-frequency electric current | High-frequency Thermal Bonding Machine | |

10 | Water-Jet Cutting | Use the water-jet cut robot to remove excess material from the part | Water-jet Cut Robot | |

11 | Bonding | Use hot melt glue to bond the two materials together | Hot Melt Glue Machine |

FAQ

Do you produce Materials or Ready Parts?

We can produce both Materials and Ready Parts, working in OEM / ODM / OBM.

What types of Non-woven Felt materials do you mainly produce?

1. Needle punched Felt (Mechanical Bonding)

2. Thermal bonded Felt (Heat Bonding)

3. Resinated Felt (Chemical Bonding)

2. Thermal bonded Felt (Heat Bonding)

3. Resinated Felt (Chemical Bonding)

Do you also produce hard layer materials like EVA?

Yes, we have our own production lines for Extrusion Lamination and Coating.

For models already on the market, can you produce ready parts?

We manufacture to order, but recommend that you do a good market research in advance,

as these sound insulation parts usually have a long replacement cycle.

as these sound insulation parts usually have a long replacement cycle.

Can we use your existing molds to custom produce ready parts?

No, because we have a strict confidentiality agreement with the customer,

the existing molds cannot be used by any third party, so you have to redevelop the molds.

the existing molds cannot be used by any third party, so you have to redevelop the molds.

Can we come and visit your factory?

Of course, we warmly welcome you to visit at any time,

we will pick you up at the airport or station and arrange all subsequent activities.

we will pick you up at the airport or station and arrange all subsequent activities.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices