Dry powder mortar mixing production line putty powder mixer dcement wall putty mixer tile adhesive manufacturing

- Category: >>>

- Supplier: Henan Fair Import & Export Trading Co. Ltd.

Share on (1601237860350):

Product Overview

Description

Product Description

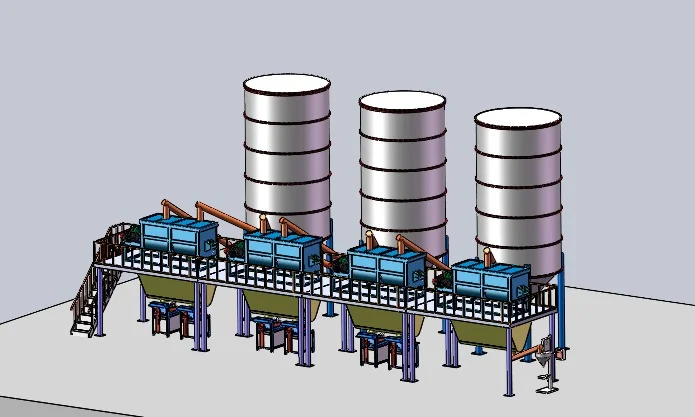

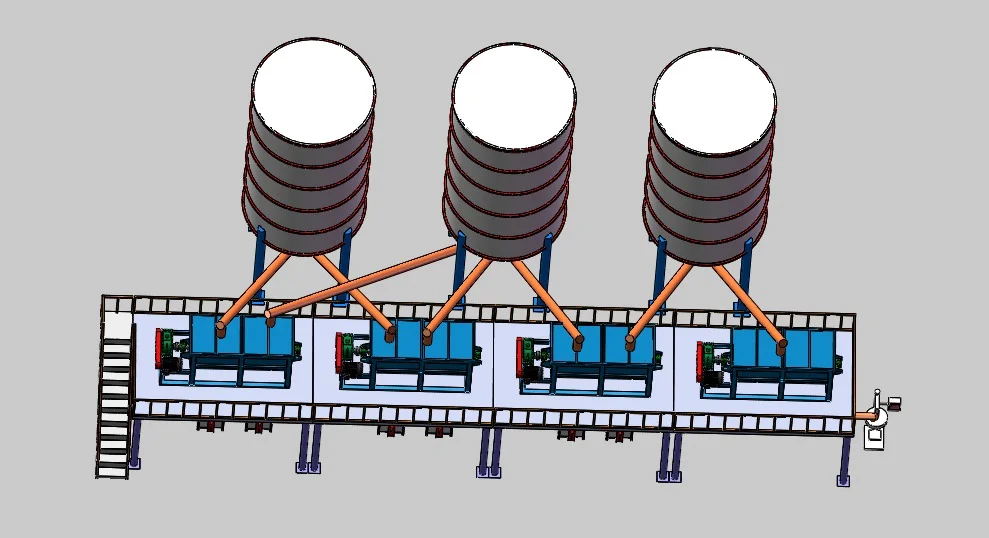

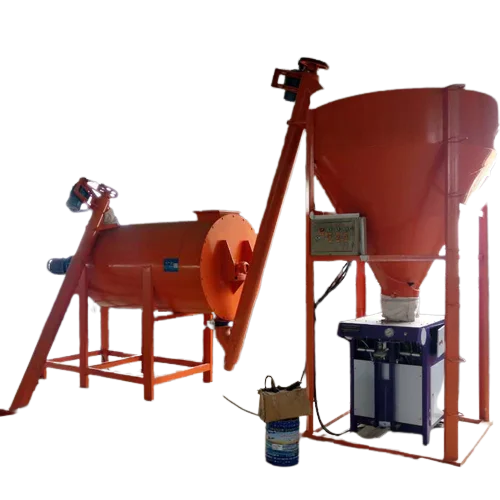

Semi-Automatic Sample Dry mortar production machinery is mainly composed of dry mortar mixer, feed screw conveyor, ribbon mixing machine, secondary hoist, a storage hopper and automatic packing machine, etc..

This system is an efficiency production system after multiple times improvement on the basis of multiple ribbons dry mortar mixer.

Mixed product will be into a storage bin through second lift machine. Then worker can carry out filing operation and not affect the next production. Matching an accurate packing machine can greatly improve production efficiency.

Mixed product will be into a storage bin through second lift machine. Then worker can carry out filing operation and not affect the next production. Matching an accurate packing machine can greatly improve production efficiency.

Application

Dry mortar mixer is able to meet the performance requirements of dry mortar, dry material, adhesive powder production needs, such as: putty powder, powder coating, masonry mortar, plaster mortar, insulation mortar, decorative mortar needed by the system and so on all kinds of dry powder mortar

Specification

Model | FM-JB-S1000 | FM-JB-S2000 | FM-JB-S3000 | FM-JB-S5000 | |||

Capacity | 1-2ton/h | 3-4ton/h | 5-6ton/h | 8-10ton/h | |||

Mixing Time | 15-20mins/batch | 15-20mins/batch | 15-20mins/batch | 15-20mins/batch | |||

Total power | 17.5kw | 22kw | 25kw | 35kw | |||

Worker required | 1-2people | 1-2people | 2-3people | 2-3people | |||

Modulation Form | Sample /Automatic /Custom | ||||||

The above data is for reference only. Please contact us for specific requirements.

Advantage:

1. Sample dry mortar plant area occupation <20 m2, height <3.5 meters,

2. worker required: 2–3-person, production capacity: 20-25 tons.

It is a reasonable and efficient simple plant with easy operation and maintenance. Its characteristic of economical becomes the top priority investment for small and medium enterprises in the limited Investment budget.

It is a reasonable and efficient simple plant with easy operation and maintenance. Its characteristic of economical becomes the top priority investment for small and medium enterprises in the limited Investment budget.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

HENAN FAIR MACHINERY CO.LTD is a leading supplier of industrial Mixing ,Packing and Crushing machinery and equipment since 1997.

FAIR MACHINERY is an ISO 9001 certified company. Our catalogue contains 20 categories of goods that can be used for both civil and industrial purposes.

Our equipment has been exported to the United States, Albania, Canada, Australia, Dominica, Switzerland, Russia ,Philippines, Mexico, Cameroon and other 162 countries and regions.

We offer custom design options, or you can provide us with your own design to meet your equipment needs in different materials and different industries that can help you improve work efficiency, save time and cost.

What we offer:

1)Best quality control

2)100% factory price

3)OEM&ODM service

4)Highly automated products

5)multiple shipping options.

6)Professional after-sales team

7) Smooth and timely communication

With us you would get The most satisfactory equipment.And we not only supply the machine but also supply you with the best turnkey solution!

FAIR MACHINERY is an ISO 9001 certified company. Our catalogue contains 20 categories of goods that can be used for both civil and industrial purposes.

Our equipment has been exported to the United States, Albania, Canada, Australia, Dominica, Switzerland, Russia ,Philippines, Mexico, Cameroon and other 162 countries and regions.

We offer custom design options, or you can provide us with your own design to meet your equipment needs in different materials and different industries that can help you improve work efficiency, save time and cost.

What we offer:

1)Best quality control

2)100% factory price

3)OEM&ODM service

4)Highly automated products

5)multiple shipping options.

6)Professional after-sales team

7) Smooth and timely communication

With us you would get The most satisfactory equipment.And we not only supply the machine but also supply you with the best turnkey solution!

FAIR Certificate

FAIR Machinery as a professional machie manufacture. And below is a certification of FAIR Machienry certification.

Customer Photos

FAQ

Q: What kind of company are you?

A:: We are a manufacturer and a trader, with more than 25 years of experience in the chemical machinery industry. We have been committed to the research and innovation of chemical machinery manufacturing to continuously follow the market demand. This is why we can provide high quality and different types of products at competitive prices.

Q: How do you ensure the normal operation of this machine?

A: Each machine is tested by our factory and other customers before shipment. We will adjust the machine to the best effect before shipment. During the warranty period, spare parts are always available and serve you free of charge.

How do we choose the machine that suits us?

A: 1. Tell us the material you want to mix and we will select the appropriate machine type for your reference

2. After selecting the appropriate machine type, please tell me the mixing and filling capacity of the machine you need

3. Finally, tell me the inner diameter of your container to help us choose the best filling head diameter for you

Q: Could you please introduce your after-sales service?

A: We can provide one-year free maintenance and auxiliary machine replacement, online video technical support, etc. All we have to do is to meet your needs and solve your problems.

Q: I'm new in our industry, but I'm planning to setup a factory, What can I do?

We offering Turnkey service from A to Z to customers, we will can suggest customer the most suitablemachines according to their Formula, Raw material. Support you Manufacturing - Installation - Training.Maintenance - Technical Support. We can introduce you supplier of raw material, bottles, labels etc.We could take you to our customer's factory to learn how they produce. We could customize machinesaccording to your real need, We could send our engineer to your factory to install machines and train yourworker of operation and maintenance.

.Q: What are your payment terms?

A: Currently, we can accept wire transfers(T/T), Western Union, Money Gram , Credit Card,

Why Choose FAIR Machinery ?

(1).Professional manufacturer with more than 25 years experience

(2).Exported to more than 97% Countries

(3).Turnkey Solution is no problem

A:: We are a manufacturer and a trader, with more than 25 years of experience in the chemical machinery industry. We have been committed to the research and innovation of chemical machinery manufacturing to continuously follow the market demand. This is why we can provide high quality and different types of products at competitive prices.

Q: How do you ensure the normal operation of this machine?

A: Each machine is tested by our factory and other customers before shipment. We will adjust the machine to the best effect before shipment. During the warranty period, spare parts are always available and serve you free of charge.

How do we choose the machine that suits us?

A: 1. Tell us the material you want to mix and we will select the appropriate machine type for your reference

2. After selecting the appropriate machine type, please tell me the mixing and filling capacity of the machine you need

3. Finally, tell me the inner diameter of your container to help us choose the best filling head diameter for you

Q: Could you please introduce your after-sales service?

A: We can provide one-year free maintenance and auxiliary machine replacement, online video technical support, etc. All we have to do is to meet your needs and solve your problems.

Q: I'm new in our industry, but I'm planning to setup a factory, What can I do?

We offering Turnkey service from A to Z to customers, we will can suggest customer the most suitablemachines according to their Formula, Raw material. Support you Manufacturing - Installation - Training.Maintenance - Technical Support. We can introduce you supplier of raw material, bottles, labels etc.We could take you to our customer's factory to learn how they produce. We could customize machinesaccording to your real need, We could send our engineer to your factory to install machines and train yourworker of operation and maintenance.

.Q: What are your payment terms?

A: Currently, we can accept wire transfers(T/T), Western Union, Money Gram , Credit Card,

Why Choose FAIR Machinery ?

(1).Professional manufacturer with more than 25 years experience

(2).Exported to more than 97% Countries

(3).Turnkey Solution is no problem

We Recommend

New Arrivals

New products from manufacturers at wholesale prices