Large capacity purple potato flakes production machine potato powder flour granule making machine line

- Category: >>>

- Supplier: Shandong Sensitar Industrial Equipment Co. Ltd.

Share on (1601238422052):

Product Overview

Description

Product Description

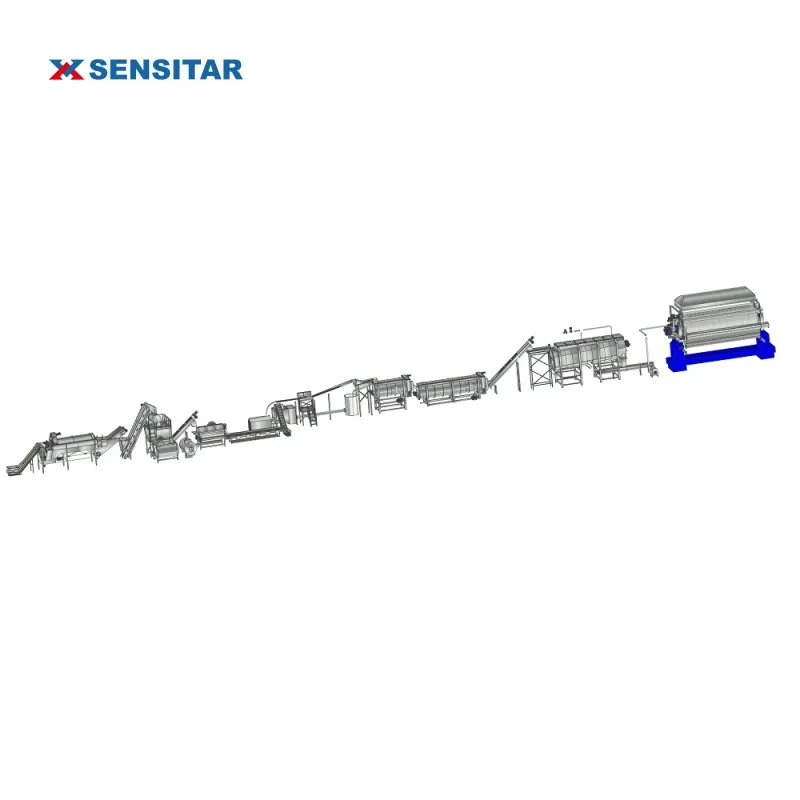

Large capacity purple potato flakes production machine potato powder flour granule making machine line

Continuously producing high-quality potato flakes and occupying a favorable position in the market depends on the ability of the management and production team, but also requires stable and reliable equipment systems, as well as the application of advanced process technology. The design concept of our Potato RF Line is completely based on the production experience and process technology of Europe, and fully meets European process requirements and quality standards.

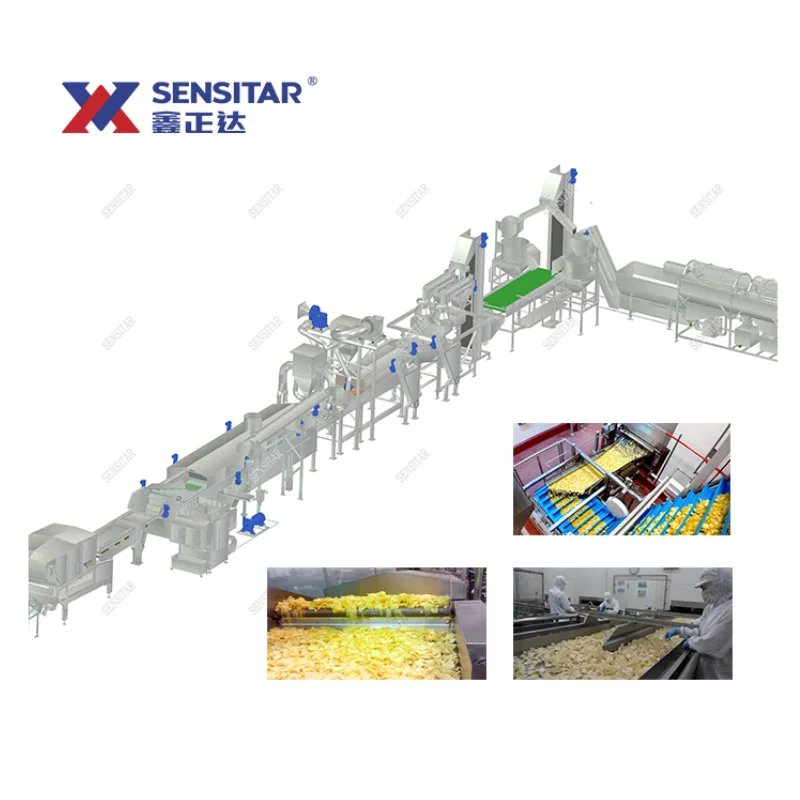

Potato Flakes Process Flow

Regular Model

The Model showed on the following table is our regular machine.

We also support machine customization service.

Type | Capacity | Heating Method | Control Type | Material |

XZDP-500 | 500kg/h | Steam heating | Automatic | SUS 304 |

XZDP-800 | 800kg/h | Steam heating | Automatic | SUS 304 |

XZDP-1000 | 1000kg/h | Steam heating | Automatic | SUS 304 |

XZDP-1600 | 1600kg/h | Steam heating | Automatic | SUS 304 |

XZDP-2000 | 2000kg/h | Steam heating | Automatic | SUS 304 |

Function:Receive the raw material and hoist the them up to the destoner and washer machine.

Dimension:4000*600 mm

Power:1.5KW

Steam peeling machine is doing peel work with hot steam, compare with traditional brushing peeling, steam peeling has higher treating capacity and peeled more thoroughed.

Capacity:3-15 tons/h

Power:4.5KW

Cut way: Using a pump to drive water, using hydraulic power to quickly transport potatoes through a horizontally fixed knife block and cutting them into thick slices in an instant and rinse the slices.

Advantages: Compared with traditional mechanical cutting method, ensure the even cutting thickness and even quality, no scrap, bring highest output rate, and higher yield.

Capacity: 3-10 tons/h

Power: 30KW

Adjusting the internal structure of potato cells, adjusting the ratio of amylose to amylopectin, and creating a texture and texture with a grainy texture. To reduce enzyme activity and sugar content to prevent discoloration, and keep best taste and color.

Spiral design ensures even temperature between top and low parts and ensure optimal blanching effect and consistent quality.

Power:7KW

Screw Cooler

By rapid cooling, the expanded starch during blanching is gelatinized on the cell structure and forms a gel layer on the cell surface.

Spiral design ensures even temperature between top and low parts and ensure optimal cooling effect and consistent quality.

Automatic temperature control, variable frequency speed regulation

Dimension:6900*1970*2200 mm

Power: 7 KW

Cooker

By rapid cooling, the expanded starch during blanching is gelatinized on the cell structure and forms a gel layer on the cell surface.

Spiral design ensures even temperature between top and low parts and ensure optimal cooling effect and consistent quality.

Automatic temperature control, variable frequency speed regulation

Dimension:Φ800×6000 mm

Power:3KW

Application scope

We will get potato flakes after the whole line.

Packing & Delivery

We usually pack our products by standard export cartons as master carton. We always choose the best and safe packaging material to make sure your orders won't be damaged during delivery.

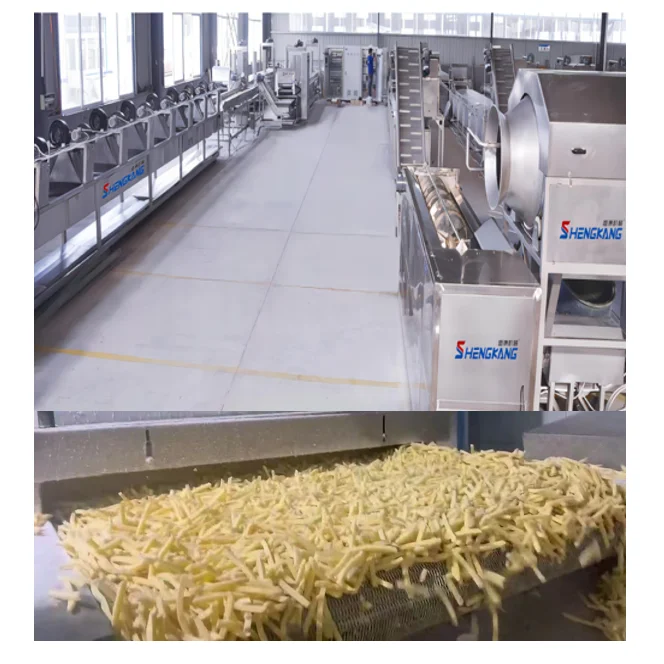

OUR WORKSHOP

Customer's site

Company Profile

Certificate ASME & CE is Available

Shandong Sensitar Industrial Equipment Co., Ltd. is a professional manufacture of food processing machine.

Include all kinds of sterilization retort, jacketed kettle , steam peeling machine, tunnel steam baking ovens, vacuum cooling machine, bone meat separator, french fries production line etc.

We have many years manufacturing experience in this industry. We also support customized equipment according to customer's requirements.

Welcome to visit our company at any time and thanks for visiting our website!

Sincerely Looking for Partner Agents!

FAQ

PAYMENT TERMS

T/T, L/C and trade assurance are acceptable, T/T will be more appreciated, 30% deposit before

production, 70% balance before shipment.

DELIVERY TIME

At least 30 days after the deposit.

PACKAGE

Standard packaging

INSTALLATION

Our engineer will go to customers site if you need, installation fee should be paid according to the contract.

WARRANTY

production, 70% balance before shipment.

DELIVERY TIME

At least 30 days after the deposit.

PACKAGE

Standard packaging

INSTALLATION

Our engineer will go to customers site if you need, installation fee should be paid according to the contract.

WARRANTY

One year warranty period and lifetime service.

Contact

We Recommend

New Arrivals

New products from manufacturers at wholesale prices