Factory sale honeycomb charcoal briquette machine coal press machine equipment production fuel briquettes

- Category: >>>

- Supplier: Henan New Guoxin Machinery Manufacturing Co. Ltd.

Share on (1601240036197):

Product Overview

Description

Honeycomb charcoal briquette machine coal press machine equipment production fuel briquettes

Product Description

Guoxin Honeycomb charcoal briquette machine coal press machine can press coal/charcoal powder into fuel briquettes, which is used for BBQ,cooking fuel,industrial boiler,heating or other fuel.The briquettes can be round, square, rectangular,rod,or other shape,can be customized.

Honeycomb charcoal briquette machine coal press machine is widely used in coal industry, metallurgy industry, chemical industry etc.

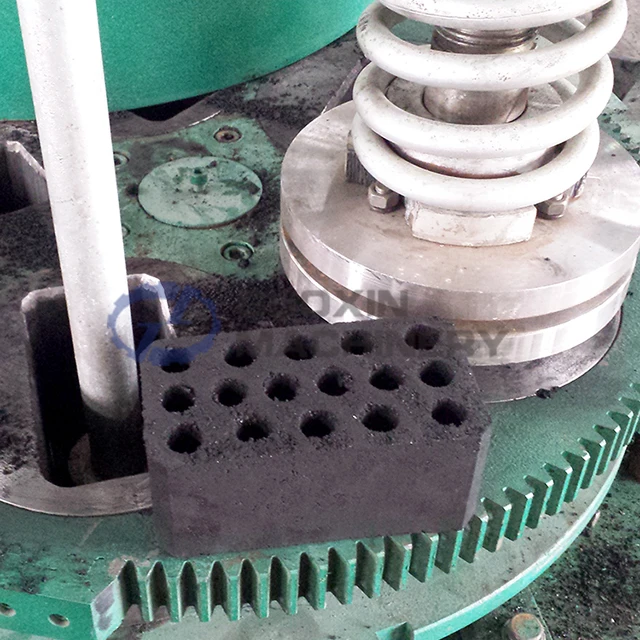

Honeycomb briquette machine

Honeycomb briquette machine

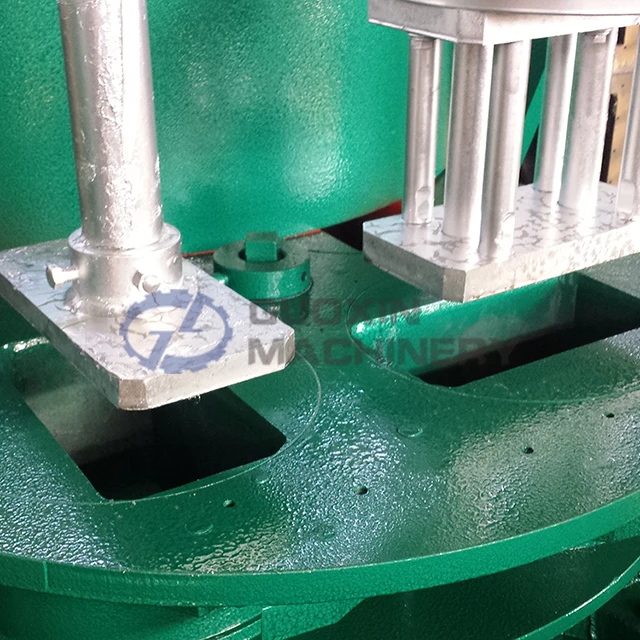

Working principle of Honeycomb charcoal briquette machine coal press machine equipment

There is a mixing feeding hopper behind the Honeycomb charcoal briquette machine coal press machine equipment,which can feed materials into the mould,then punching press material to briquettes.The briquettes are discharged onto the conveyor belt and then transported out.

According to customer different requirements,we provide different size moulds Honeycomb charcoal briquette machine coal press machine,Briquettes diameter or lenth can be 30-220mm,Height can be 50-80mm. We usually have round, square, rectangular,rod shapes, and can also customize other special shapes.

Honeycomb charcoal briquette machine coal press machine pressing holes on the briquettes that make them look like honeycomb. These holes expand the briquettes' surface, so that briquettes burn fully and reduce the waste of resources.

Product Parameters

Model | Capacity | Power | Machine size | Weight |

GX-140 | 1000KG | 7.5kw | 1.35*1.2*1.76m | 1500kg |

GX-160 | 1000KG | 7.5kw | 1.55*1.4*1.9m | 2200kg |

GX-220 | 1500KG | 15kw | 1.95*1.65*2.05m | 3000kg |

GX-260 | 2000kg | 15kw | 2*1.7*2.15m | 4300kg |

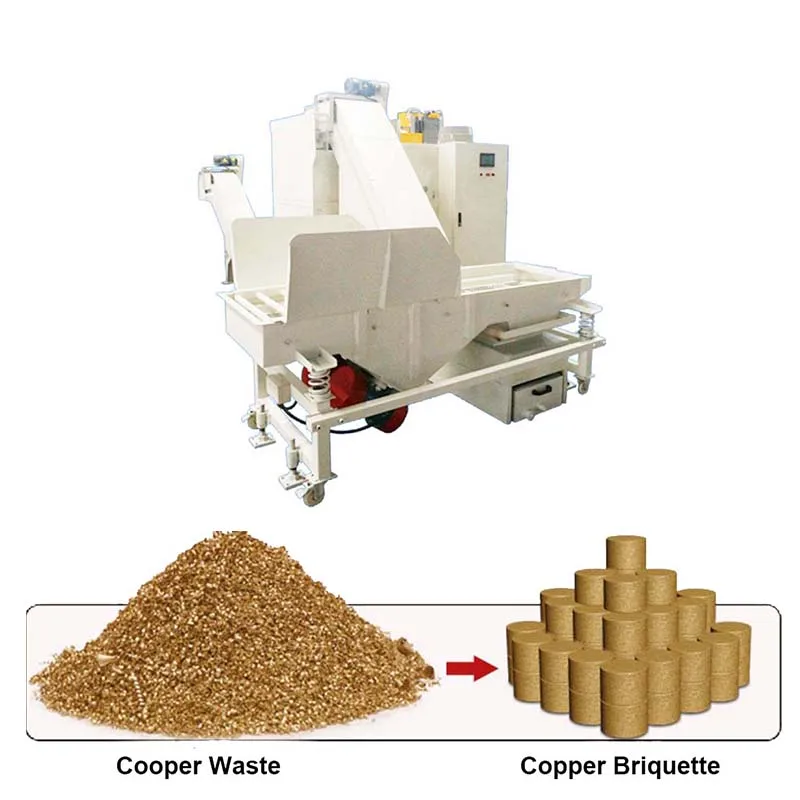

Production Line

We provide the whole automatic honeycomb briquettes productiong line,such as crusher,Chain plate feeder, conveyor,etc.we also can do charcoal making machine.turn agricultural waste and forestry waste into charcoal.then through honeycomb briquettes press machine or other briquette machine to make fuel briquettes.

Related products:

Customer Photos

Honeycomb charcoal briquette machine coal press machine equipment production fuel briquettes

Packing & Delivery

Packing:We will wrap the machine with film to avoid damp and scattered during transportation,and thicken the export wooden box to surround the machine to protect the machine from impact and friction.The size depends on the machine We can provide multiple channels of transportation.

Delivery:We guarantee that the freight forwarders we use have more than 5 years of cooperation history, provide you with fast timeliness and economic prices, and ensure the safety and integrity of your machines.

Delivery:We guarantee that the freight forwarders we use have more than 5 years of cooperation history, provide you with fast timeliness and economic prices, and ensure the safety and integrity of your machines.

Company Profile

As a professional manufacturer of charcoal briquette making machine,GUOXIN have research and development a complete set of charcoal making machine carbonization furnace,charcoal briquette machine,coal press machine and a series of related products.Each set of charcoal machine is mature and successful.Choose us and believe in us.

FAQ

1. What is your Business Model? Trading company or factory?

We are a 25 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

2. What is the Installation of your Honeycomb charcoal briquette machine coal press machine?

2. What is the Installation of your Honeycomb charcoal briquette machine coal press machine?

One machine usually no need to install, We have operation explanation video. The whole charcoal briquettes production line we provide installation service, Guoxin company has several experienced technicians with passports ready to go for installation.

3.what can you buy from us?

Wood Charcoal Making Machine, Coal Briquette Machine, Shisha Briquette Press Machine, Hydraulic Shisha Briquette Press Machine, Coconut Charcoal Briquette Machine.etc.

4. What should I provide to get the suitable quotation?

3.what can you buy from us?

Wood Charcoal Making Machine, Coal Briquette Machine, Shisha Briquette Press Machine, Hydraulic Shisha Briquette Press Machine, Coconut Charcoal Briquette Machine.etc.

4. What should I provide to get the suitable quotation?

①What is your raw material?

②What is the capacity per hour you required?

③What is the final product use?

We Recommend

New Arrivals

New products from manufacturers at wholesale prices