New Automatic Puffed Core Filling Snack Food Extruder Machine PLC & Motor Powered Puff Filling for Food Shops

- Category: >>>

- Supplier: Himax Machinery Inc

Share on (1601240792313):

Product Overview

Description

Products Description

Puff snack food processing line ,We can generalize the puff snack foods production with "Low cost, high profits". This processing line can be used for the production all kinds of puff snacks, we will design the moulds with novel shapes according to customers'specific requirement on the shapes of their aimed products. The production line is from feeding materials, extruding,Forming,Filling and cutting, drying, oil spraying to finished productsare done once time fully automatically.

Our processing line capacity:100-150kg/h;200-260kg/h;300-500kg/h;1000kg/h

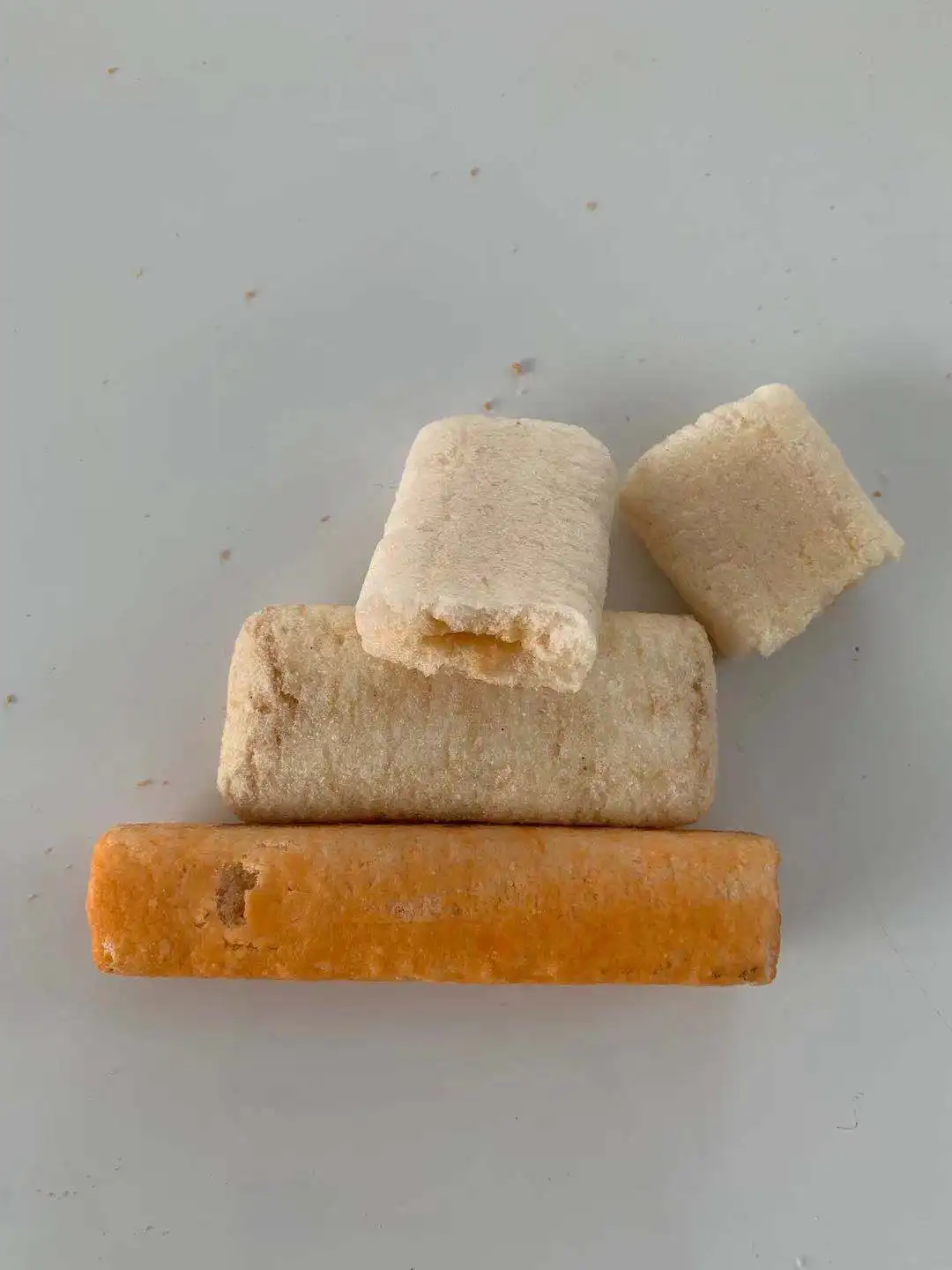

Sample

Raw material: corn flour, wheat flour, rice flour, and other grains flour etc.

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder.

we could design the molds with novel shapes according to customers'specific requirement on the shapes of their aimed products.

we could design the molds with novel shapes according to customers'specific requirement on the shapes of their aimed products.

Product Parameters

PARAMETER INTERPRETATION

Model | Installed Power(kw) | Output(kg/h) | Size/mm |

HM65 | 140 | 100-150 | 28000*1200*2200 |

HM70 | 194 | 200-260 | 32000*1500*2200 |

HM85 | 245 | 300-500 | 35000*1500*3500 |

Details Images

Mixer

mixer makes the raw material adding to water and liquid chemical additive fully mixed

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Screw Conveyor

The mixed materials can be conveyed in the stainless steel roller to the feeding machine (feeder) of extruder without any leaking,

dusting and pollution; Feed quantity and speed is even and stable.

dusting and pollution; Feed quantity and speed is even and stable.

Twin Screw Extruder

The twin -screw extruder is made of the feeding system, extruding system, cutting system, heating system, conditioner and

controlling system.

1. The screws are made of the alloy steel;

2. The forced lubrication system ;

3. Auto-temperature control system;

4, Auto-speed control system

5. Self-cleaning.

6.With the bearing is NSK which made from japan.

controlling system.

1. The screws are made of the alloy steel;

2. The forced lubrication system ;

3. Auto-temperature control system;

4, Auto-speed control system

5. Self-cleaning.

6.With the bearing is NSK which made from japan.

Air Conveyor

1. Air conveyor conveys the food relying on the wind-force from the blower.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

Dryer

The heating way is gas/furel oil heating.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

Product packaging

Company Profile

1.Q:what's the shape you can make?

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mold in the extruder.

.2 Q:What is your delivery time?

30 days after down payment.We have our own forwarder and we have long term cooperation with each customers and have closely relationship with each other,so there is no problem.

3. Q:Payment Way?

T/T /Alibaba Trade Assurance/ L/C or other ways.

4.Q:What's the shipping way?

According to YOUR demands to decide ship by sea or air

.2 Q:What is your delivery time?

30 days after down payment.We have our own forwarder and we have long term cooperation with each customers and have closely relationship with each other,so there is no problem.

3. Q:Payment Way?

T/T /Alibaba Trade Assurance/ L/C or other ways.

4.Q:What's the shipping way?

According to YOUR demands to decide ship by sea or air

5.Q:Can you accept OEM or ODM?

Yes, of course. logo is also acceptable. ODM is also welcome

5.Q:How is Warranty?

1)One years guarantee from the delivery date of this machine under the normal operation of one shift per day!

2)We will be responsible for maintenance of damaged part which is under normal situation during warranty period,and all the round-trip courier transportation cost of damaged /repaired replacement parts in warranty period should be borne by the buyer.Wearing parts are not included.

3)24 hour technical support by email or calling.

4)User-friendly English manual for machine using and maintaining.

6.Q:Our service?

1)One-stop service,meet needs of the customers from individuals to international companies.

2)Separate trading office: Himax machinery with 14 years experienced sales offering full scale service.

3)After sale service:experienced and knowledgeable team of technical support,provide engineer oversea service.

Yes, of course. logo is also acceptable. ODM is also welcome

5.Q:How is Warranty?

1)One years guarantee from the delivery date of this machine under the normal operation of one shift per day!

2)We will be responsible for maintenance of damaged part which is under normal situation during warranty period,and all the round-trip courier transportation cost of damaged /repaired replacement parts in warranty period should be borne by the buyer.Wearing parts are not included.

3)24 hour technical support by email or calling.

4)User-friendly English manual for machine using and maintaining.

6.Q:Our service?

1)One-stop service,meet needs of the customers from individuals to international companies.

2)Separate trading office: Himax machinery with 14 years experienced sales offering full scale service.

3)After sale service:experienced and knowledgeable team of technical support,provide engineer oversea service.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices