RW74 Stainless Steel Back Pressure Valve for Hydrogen

- Category: >>>

- Supplier: Shenzhen Wofly Technology Co. Ltd.Shenzhen Ltd.

Share on (1601241566231):

Product Overview

Description

Specification

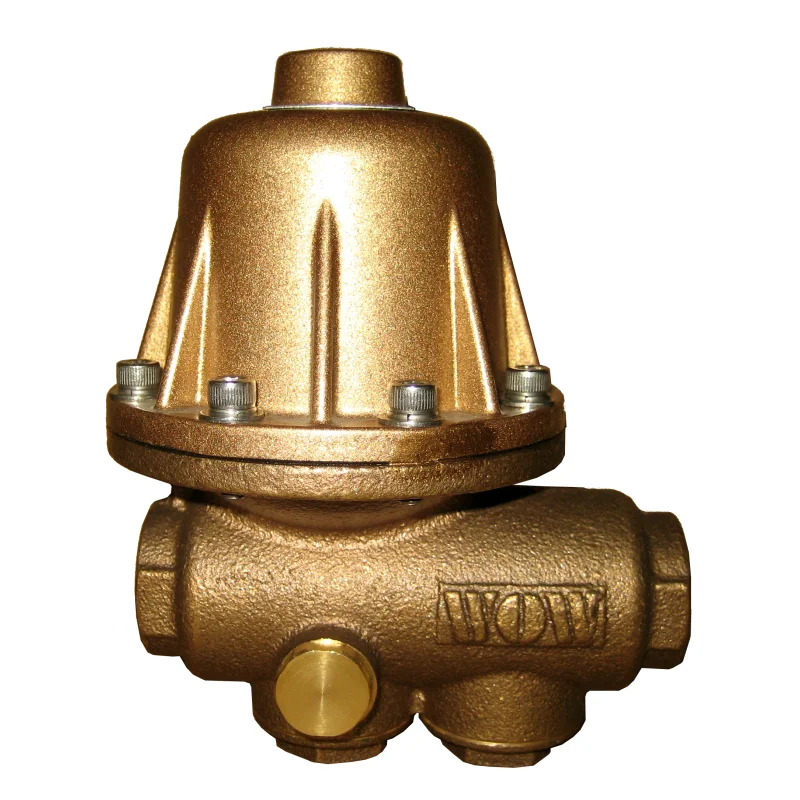

RW74 Back Pressure Valve Product Overview

RW74 back pressure valve is a high-performance valve designed for hydrogen media. The valve body is made of high quality stainless steel 316L, which has excellent corrosion resistance and can be operated stably for a long time in hydrogen environment.RW74 Back Pressure Valve Main Technical Parameters

1. Inlet pressure range: 5 - 15 bar, can meet the pressure requirements under different working conditions.

2. valve body interface: itself with a 1-inch female threaded interface, through the connection of a 2-inch female threaded connector, easy to connect with the pipeline system.

3. Pressure Gauge: Equipped with a 30psi pressure gauge, real-time monitoring of pressure changes before and after the valve.

4. Maximum flow rate: up to 210 Nm³/hour, capable of meeting the requirements of higher flow rates of hydrogen transportation.

1. Inlet pressure range: 5 - 15 bar, can meet the pressure requirements under different working conditions.

2. valve body interface: itself with a 1-inch female threaded interface, through the connection of a 2-inch female threaded connector, easy to connect with the pipeline system.

3. Pressure Gauge: Equipped with a 30psi pressure gauge, real-time monitoring of pressure changes before and after the valve.

4. Maximum flow rate: up to 210 Nm³/hour, capable of meeting the requirements of higher flow rates of hydrogen transportation.

item | value |

Application | General |

Place of Origin | China |

Guangdong | |

Power | Manual |

Structure | Pressure Reducing |

Customized support | OEM, ODM |

Port Size | 2in |

Warranty | 1 years |

Model Number | RW74 |

Temperature of Media | Normal Temperature |

Brand Name | AFKLOK |

Media | Gas |

Product name | Stainless Steel Back Pressure Valve |

Medium | Gas |

Material | SS316L |

Pressure | 0.5-1.5MPa |

Weight | 3.7kg(Without packaging) |

RW74 Back Pressure Valve Features

1. Precise control: it can accurately control the back pressure of hydrogen to ensure the stability and safety of system operation.

2. High reliability: Stainless steel 316L material ensures the strength and durability of the valve body, reducing the frequency of maintenance and replacement.

3. Convenient installation: 1-inch female threaded port and 2-inch female threaded connector are designed to make the installation process more convenient.

4. Wide range of application: suitable for various hydrogen delivery and storage systems, such as hydrogen refueling stations, chemical plants and so on.

1. Precise control: it can accurately control the back pressure of hydrogen to ensure the stability and safety of system operation.

2. High reliability: Stainless steel 316L material ensures the strength and durability of the valve body, reducing the frequency of maintenance and replacement.

3. Convenient installation: 1-inch female threaded port and 2-inch female threaded connector are designed to make the installation process more convenient.

4. Wide range of application: suitable for various hydrogen delivery and storage systems, such as hydrogen refueling stations, chemical plants and so on.

RW74 Back Pressure Valve Precautions

1. Before installation and use, please make sure the specifications and parameters of the valve match the system requirements.

2. check the sealing and working condition of the valves regularly, if there is any abnormality, it should be repaired or replaced in time.

3. Avoid external impact and damage to the valve, and keep its appearance clean.

4. operate in strict accordance with the operating procedures to ensure the safety of personnel and equipment.

1. Before installation and use, please make sure the specifications and parameters of the valve match the system requirements.

2. check the sealing and working condition of the valves regularly, if there is any abnormality, it should be repaired or replaced in time.

3. Avoid external impact and damage to the valve, and keep its appearance clean.

4. operate in strict accordance with the operating procedures to ensure the safety of personnel and equipment.

Product Description

Back Pressure Valve

The RW74 back pressure valve is primarily used for hydrogen media. The inlet pressure is in the range of 5 to 15 bar and the valve body has a 1-inch female connection. For connection requirements, a 2-inch female threaded fitting is attached to the inlet and outlet. Equipped with a pressure gauge of 30 psi, this backpressure valve has a maximum flow rate of 210 standard cubic meters per hour and is made of stainless steel 316L, which provides good corrosion resistance and is suitable for a wide range of media, including hydrogen.The applicable medium of the product is customized in accordance with customer requirements of a pressure flow medium are in line with customer requirements of one of the, if you also have the need, please provide your pressure, flow, medium and the use of the scene, so that we can give a good selection.

Project Cases

Packing & Delivery

FAQ

Q1:How stable is this backpressure valve in hydrogen medium?

A: The valve body of RW74 backpressure valve is made of stainless steel 316L, which has good corrosion resistance to hydrogen, and has been rigorously tested to operate stably in hydrogen medium.

Q2: Under what conditions is the maximum flow rate of 210Nm³/h achieved?

A: The maximum flow rate of 210Nm³/h can be achieved when the inlet pressure is within the specified range of 5 - 15bar and the system is operating normally.

Q3: Is it safe and reliable to connect the 1“ female threaded connection of the valve body to the 2” female threaded fitting?

A: This connection is safe and reliable when installed correctly and with the proper seals. Installation instructions are provided to ensure a tight and stable connection.

Q4: How do I adjust the back pressure valve to control pressure?

A: Pressure can be controlled by adjusting the regulator on the valve. Normal we are adjusted according to your use pressure, if you still need to adjust we can provide tutorials on adjusting pressure.

Q5: What happens if the actual flow rate exceeds the maximum flow rate?

A: It may lead to unstable pressure, degradation of valve performance or even damage to the valve, so you should ensure that the actual flow rate does not exceed the maximum flow rate.

Q6: What maintenance work is required on a daily basis?

A: Regularly check the sealing of the valve, whether the pressure indication is normal or not, as well as clean the surface of the valve. If any abnormality is found, it should be dealt with promptly or contact the manufacturer for maintenance.

Q7: How often do I need to perform maintenance?

A: The specific maintenance frequency depends on the use of the environment and the intensity of use, it is generally recommended to carry out inspection and maintenance every six months.

Q8:Can it be connected with pipes made of other materials?

A: It can be connected with pipes made of other materials, but the sealing and compatibility of the connection should be ensured to avoid leakage or other problems due to material mismatch.

A: The valve body of RW74 backpressure valve is made of stainless steel 316L, which has good corrosion resistance to hydrogen, and has been rigorously tested to operate stably in hydrogen medium.

Q2: Under what conditions is the maximum flow rate of 210Nm³/h achieved?

A: The maximum flow rate of 210Nm³/h can be achieved when the inlet pressure is within the specified range of 5 - 15bar and the system is operating normally.

Q3: Is it safe and reliable to connect the 1“ female threaded connection of the valve body to the 2” female threaded fitting?

A: This connection is safe and reliable when installed correctly and with the proper seals. Installation instructions are provided to ensure a tight and stable connection.

Q4: How do I adjust the back pressure valve to control pressure?

A: Pressure can be controlled by adjusting the regulator on the valve. Normal we are adjusted according to your use pressure, if you still need to adjust we can provide tutorials on adjusting pressure.

Q5: What happens if the actual flow rate exceeds the maximum flow rate?

A: It may lead to unstable pressure, degradation of valve performance or even damage to the valve, so you should ensure that the actual flow rate does not exceed the maximum flow rate.

Q6: What maintenance work is required on a daily basis?

A: Regularly check the sealing of the valve, whether the pressure indication is normal or not, as well as clean the surface of the valve. If any abnormality is found, it should be dealt with promptly or contact the manufacturer for maintenance.

Q7: How often do I need to perform maintenance?

A: The specific maintenance frequency depends on the use of the environment and the intensity of use, it is generally recommended to carry out inspection and maintenance every six months.

Q8:Can it be connected with pipes made of other materials?

A: It can be connected with pipes made of other materials, but the sealing and compatibility of the connection should be ensured to avoid leakage or other problems due to material mismatch.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices