Powder Briquette Machine/briquetting Machine For Aluminium/metal Powder

- Category: >>>

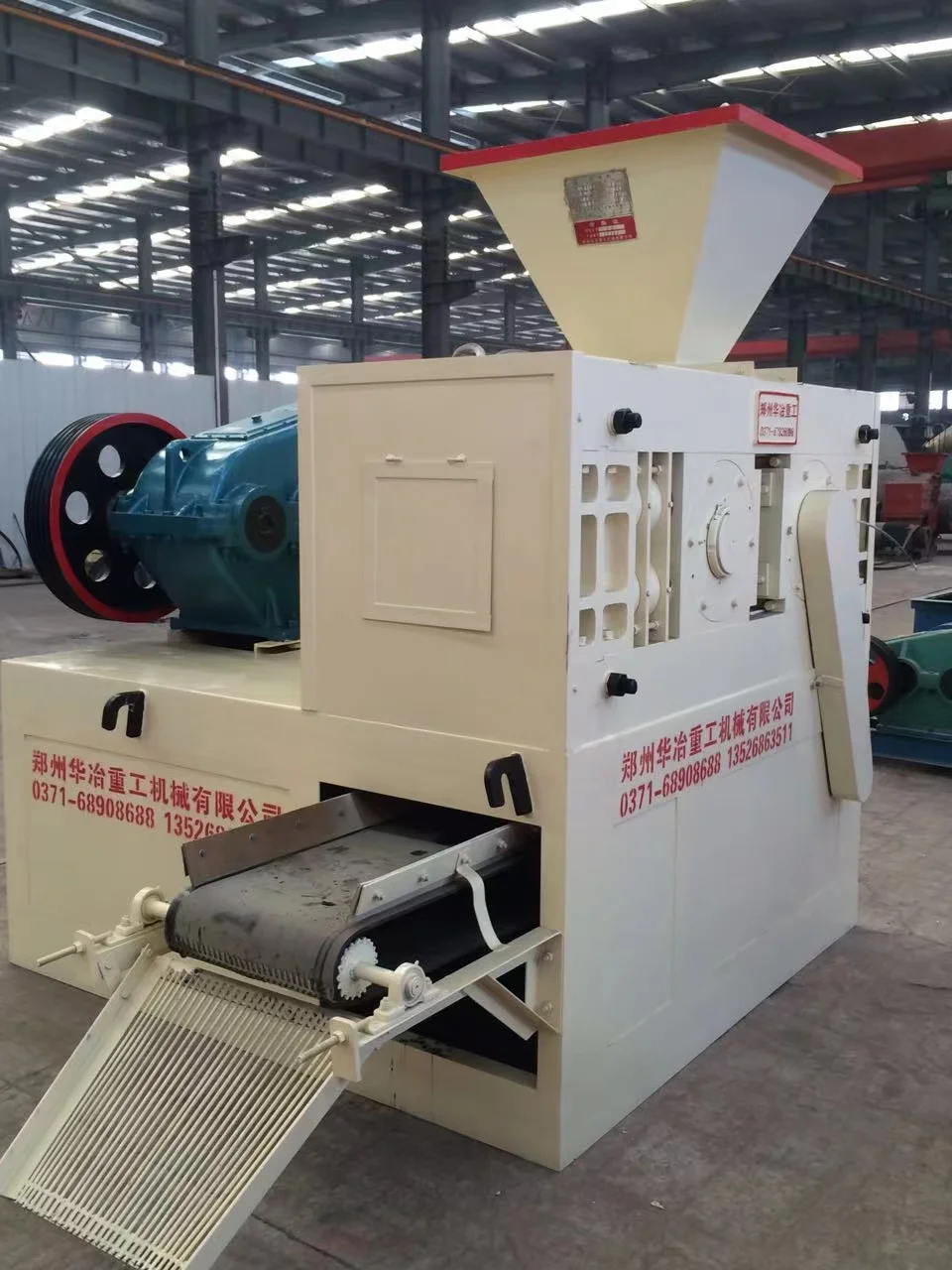

- Supplier: Zhengzhou Huaye Heavy Industry & Machinery Co. Ltd.

Share on (1601241662072):

Product Overview

Description

High Density Roll Type Briquetting Machine Strong Briquette Ball Press Machine

Coal dust briquette machine , mainly used to suppress difficult molding powder materials ,characterized by forming pressure , the host rpm adjustable, with a spiral feeding device.

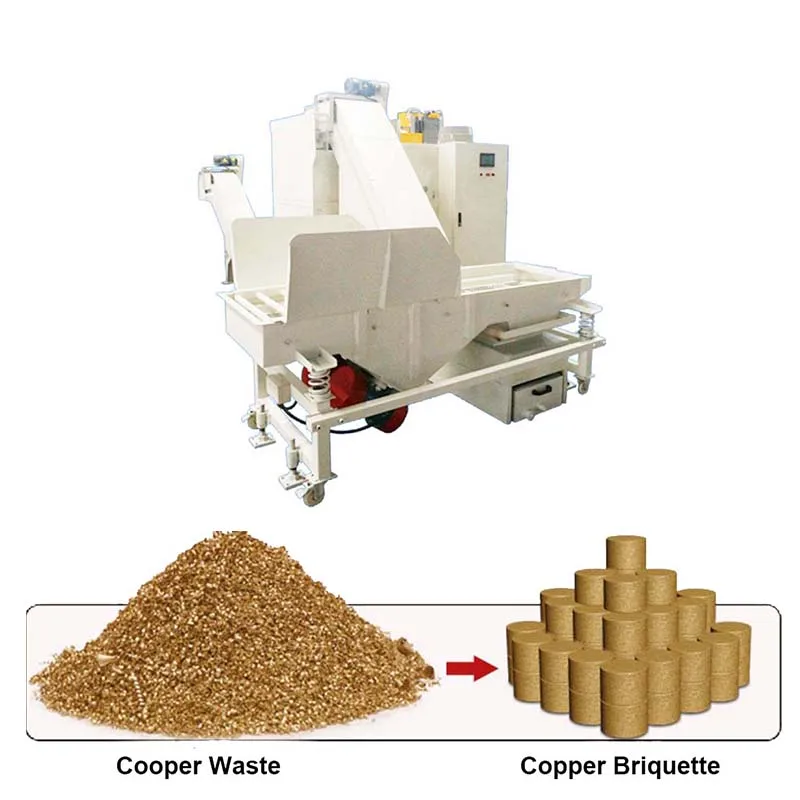

Coal dust briquette machine can be used to suppress coal , iron , coke , aluminum powder, iron , iron oxide skin, toner , slag ,gypsum, tailings , sludge , kaolin , activated carbon, coke powder and other end,Powder,waste,waste residues, are widely used in refractory , power plants , metallurgy,chemical , energy,transportation, heating , etc. , produced by the compression molding machine after the briquette materials , energy saving , easy to transport , increase of wastes Utilization, with good economic and social benefits .

Coal dust briquette machine can be used to suppress coal , iron , coke , aluminum powder, iron , iron oxide skin, toner , slag ,gypsum, tailings , sludge , kaolin , activated carbon, coke powder and other end,Powder,waste,waste residues, are widely used in refractory , power plants , metallurgy,chemical , energy,transportation, heating , etc. , produced by the compression molding machine after the briquette materials , energy saving , easy to transport , increase of wastes Utilization, with good economic and social benefits .

Principles of operation :

The material is fed into the hopper of the molding machine evenly from the material inlet. The adjusting plate on the hopper makes the material enter into the middle of the roller uniformly, and the roller running in the opposite direction compresses the material, the molding pressure increases gradually, and the molding pressure reaches the maximum value at the center line of the roller, and the molding pressure decreases rapidly after the material passes through the line, so that the material forms into a ball and comes out of the ball smoothly.

Applicable raw material: water content should be 12%-14%/granule size <5mm. Such as: anthracite coal, coal powder, coke carbon

dust, carbon powder, charcoal powder, carbon black, iron ore fines, mineral powder, metal dust, iron dust, mill scale, manganese of fines, fluorite powder, barbecue coal, gypsum powder, chemical salt, ferrosilicon powder, nickel alloy, blast furnace ash, converter dust etc.

dust, carbon powder, charcoal powder, carbon black, iron ore fines, mineral powder, metal dust, iron dust, mill scale, manganese of fines, fluorite powder, barbecue coal, gypsum powder, chemical salt, ferrosilicon powder, nickel alloy, blast furnace ash, converter dust etc.

Technical Parameter

Product advantages

FAQ

1. Are you manufacture or trading company?

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before

shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5.If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

We are factory, established in 2003.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before

shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5.If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices