Press Brake Tooling Protective Film of Polyurethane for Stainless Steel Anti Scratch/Urethane Die Cover Film

- Category: >>>

- Supplier: Maanshan Wila CNC Machine Tools Co. Ltd.Maanshan Ltd.

Share on (1601241681046):

Product Overview

Description

S/R | Specifications | Quantity | Unit | Appilcation range |

1 | 110*0.3 milk white | 30 | meters | SS.sheet thickness below 1.0mm |

2 | 150*0.3 milk white | 30 | meters | SS.sheet thickness below 1.0mm |

3 | 110*0.3 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

4 | 150*0.3 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

5 | 110*0.5 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

6 | 150*0.5 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

7 | 200*0.5 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

8 | 300*0.5 milk white | 30 | meters | SS.sheet thickness below 2.0mm |

9 | 110*0.6 milk white | 30 | meters | SS.sheet thickness from 1.0mm to 2.5mm |

10 | 150*0.6 milk white | 30 | meters | SS.sheet thickness from 1.0mm to 2.5mm |

11 | 110*0.8 milk white | 30 | meters | SS.sheet thickness from 2.0mm to 4.0mm |

12 | 150*0.8 milk white | 30 | meters | SS.sheet thickness from 2.0mm to 4.0mm |

13 | 150*1.0 milk white | 30 | meters | SS.sheet thickness from 3.0mm to 5.0mm |

14 | 300*1.0 milk white | 30 | meters | SS.sheet thickness from 3.0mm to 5.0mm |

15 | 110*0.6 milk white | 30 | meters | SS.sheet thickness from 1.0mm to 2.5mm |

16 | 110*0.6 milk Orange | 30 | meters | SS.sheet thickness from 1.0mm to 2.5mm |

Product Overview

Urethane Die Cover Film

Background conditions:

In the process of bending, due to the influence of mold, bending pressure and other factors, the plate often produces indentation, especially aluminum plate and stainless steel plate, which will seriously affect the appearance of the product. In order to avoid or reduce these indentations, many manufacturers choose to carry out secondary processing, regrinding after bending or painting the plate. Some manufacturers coating the plate before bending to avoid indentation. However, these operations are not only time-consuming and labor-consuming, but also have little effect.

In the process of bending, due to the influence of mold, bending pressure and other factors, the plate often produces indentation, especially aluminum plate and stainless steel plate, which will seriously affect the appearance of the product. In order to avoid or reduce these indentations, many manufacturers choose to carry out secondary processing, regrinding after bending or painting the plate. Some manufacturers coating the plate before bending to avoid indentation. However, these operations are not only time-consuming and labor-consuming, but also have little effect.

Being extremely durable the Die Cover Film will perform for numerous parts before having to be replaced with a new length.

FEATURES AT A GLANCE

How does it work?

urethane die-cover film forms a soft durable barrier between the pressure points of the brake punch and die eliminating the scuffing from metal on metal contact. Typically the length of the die contact area is covered and then the press operation continues as normal. Thicker versions of CLEAN BRAKE are used for heavier gauge applications.

urethane die-cover film forms a soft durable barrier between the pressure points of the brake punch and die eliminating the scuffing from metal on metal contact. Typically the length of the die contact area is covered and then the press operation continues as normal. Thicker versions of CLEAN BRAKE are used for heavier gauge applications.

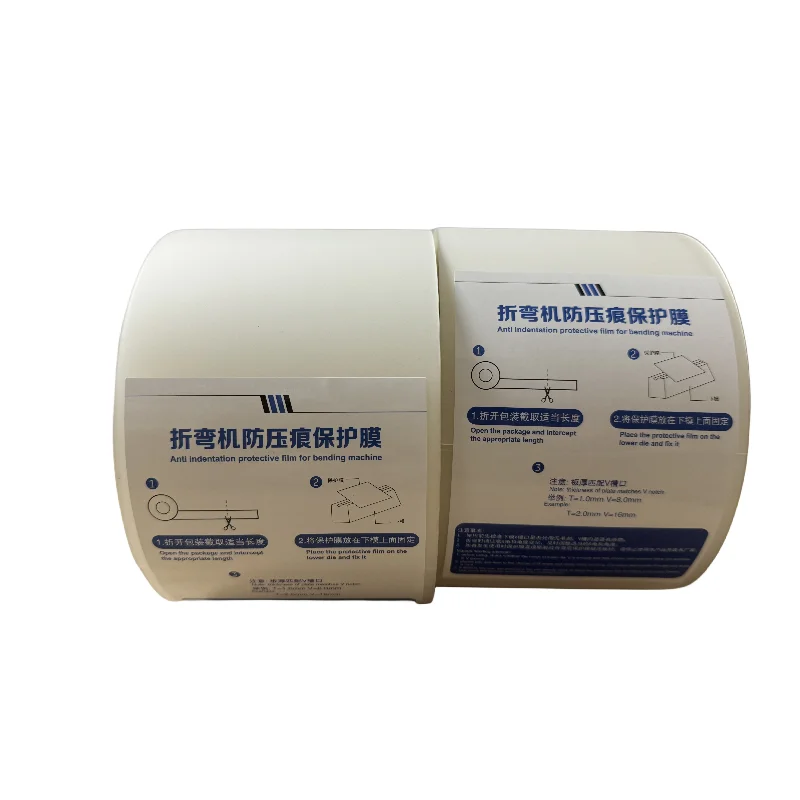

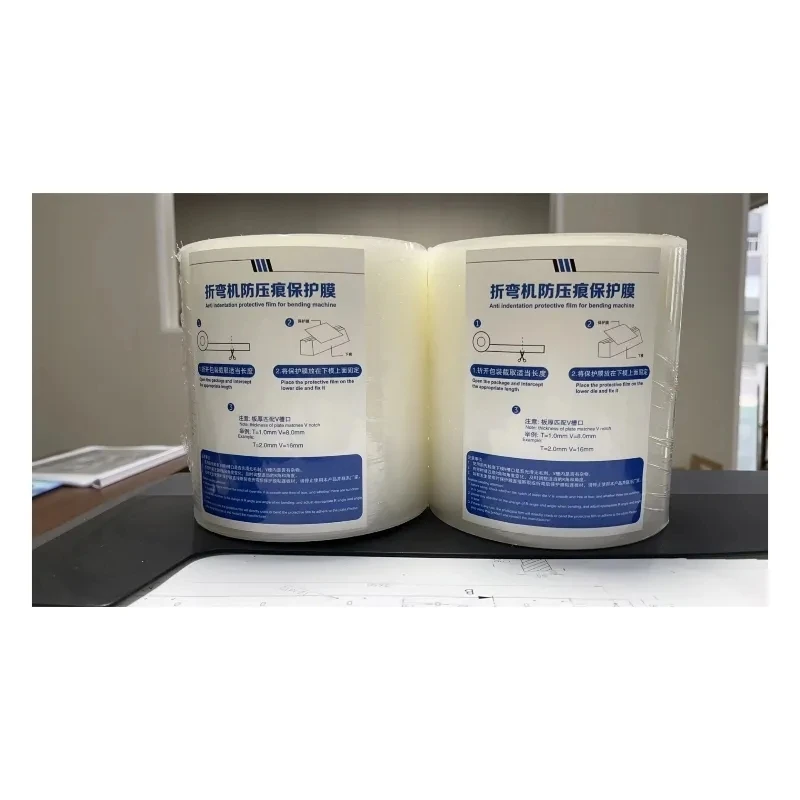

Physical picture

Physical picture

Physical picture

Why Choose Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices