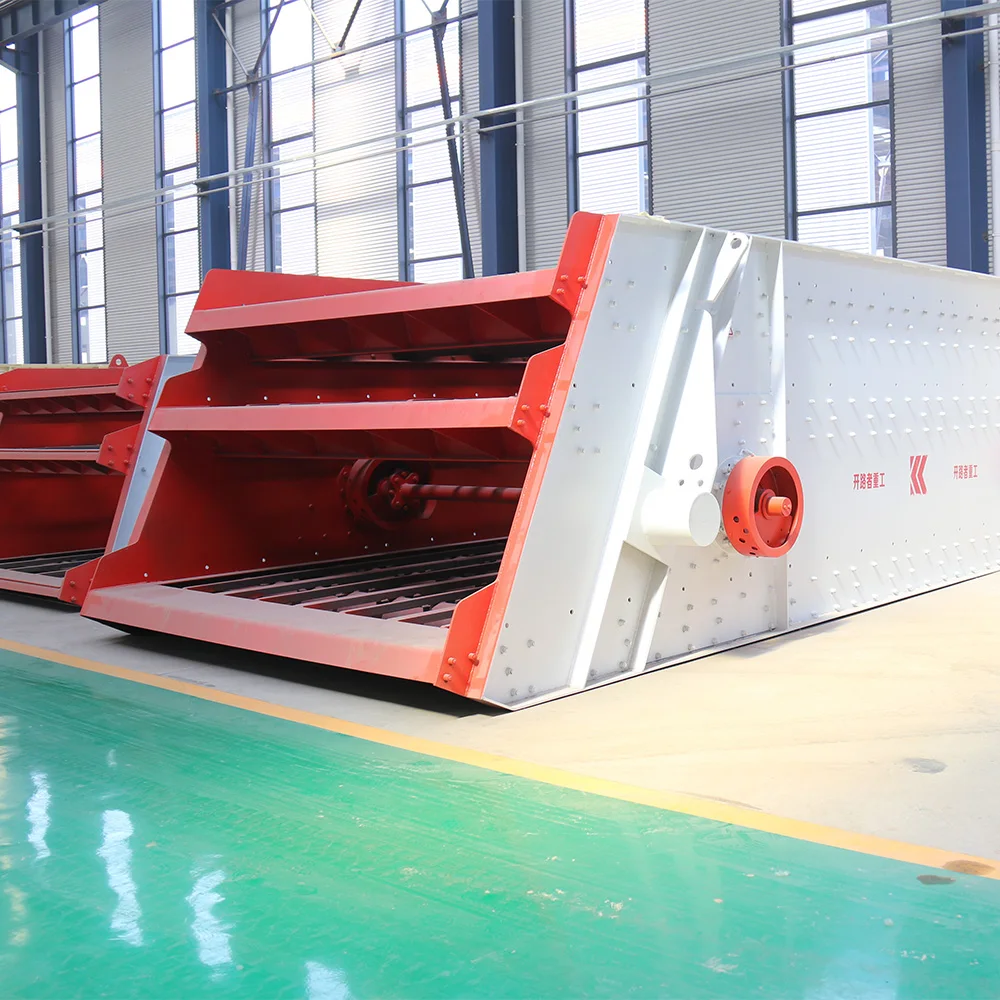

Commercial flour sea salt production Swinging screen separator

- Category: >>>

- Supplier: Xinxiang Tianfeng Vibration Machinery Co. Ltd.Xinxiang Ltd.

Share on (1601241866889):

Product Overview

Description

Product Description

Calcium Carbonate Round Swing Screen Circular Tumbler Vibrating Sieve Sifter Screening Machine

Tumbler vibrating screen machine is an efficient sieving equipment which is designed to meet the large out put, high-density

sieving of the manufacturers. It is the most effective simulation of artificial sieving movement (sieving precision, efficiency,

service life is 5-10 times than the common cylinder sieve), for the processing of all the fine and ultra-fine powder and special

materials, particularly suitable for materials which are difficult to classify. Because of the motion trajectory of the griddle

box, the Tumbler screen machine is also called compound circle screen. The

vibration force produced by the drive system is a kind of inertia force which is circling the dead axle and changing regularly.

Intrinsically, it is a kind of centrifugal force given by the eccentricity mass circling around the dead axle. The sieve is

ususlly installed horizontally or with tiny angle(0°-5°).

Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice,

etc.

Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

Mechanical industry: casting sand, powder metallurgy, electromagnetic material andmetal powder, etc.

sieving of the manufacturers. It is the most effective simulation of artificial sieving movement (sieving precision, efficiency,

service life is 5-10 times than the common cylinder sieve), for the processing of all the fine and ultra-fine powder and special

materials, particularly suitable for materials which are difficult to classify. Because of the motion trajectory of the griddle

box, the Tumbler screen machine is also called compound circle screen. The

vibration force produced by the drive system is a kind of inertia force which is circling the dead axle and changing regularly.

Intrinsically, it is a kind of centrifugal force given by the eccentricity mass circling around the dead axle. The sieve is

ususlly installed horizontally or with tiny angle(0°-5°).

Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice,

etc.

Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

Mechanical industry: casting sand, powder metallurgy, electromagnetic material andmetal powder, etc.

work principle

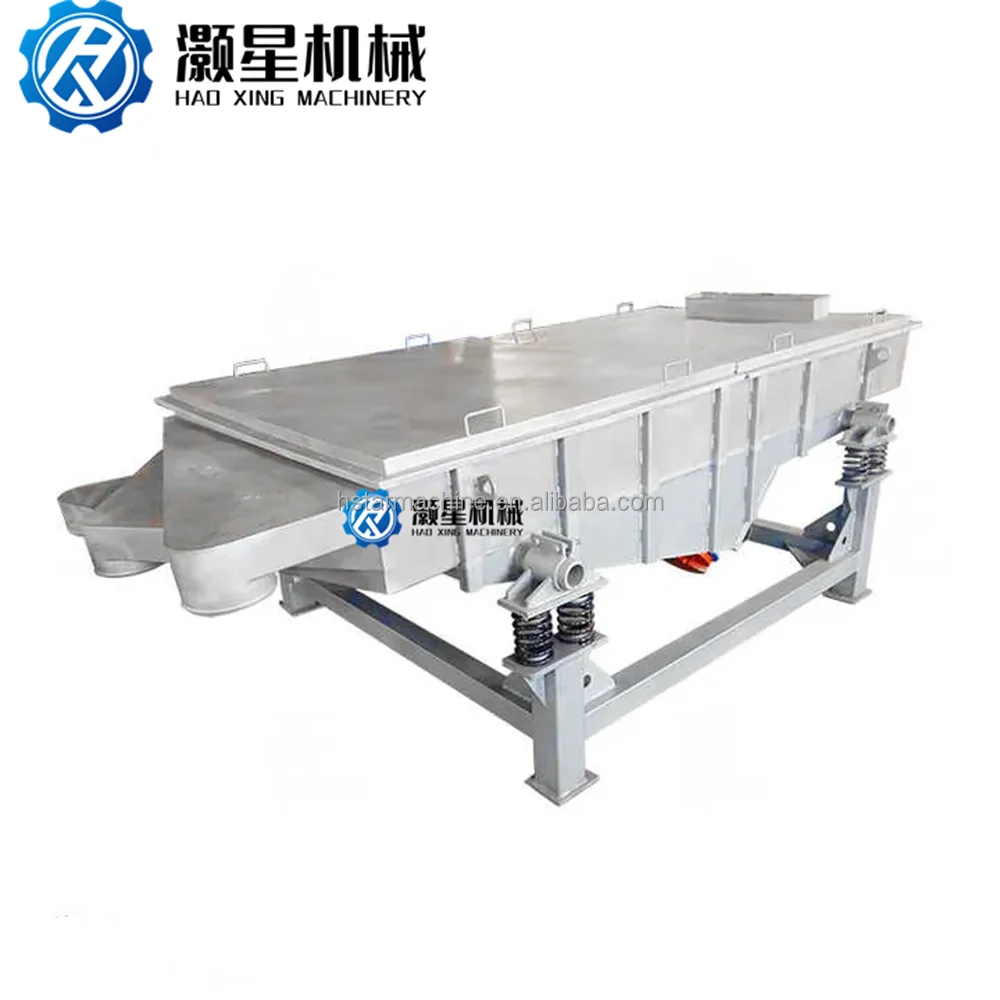

YBS series vibrating and swinging screen is a low-frequency rotary vibrating screen imitating manual shaking. The principle is

that the instantaneous motion is the combination of the radial displacement and the circular motion with this displacement as the

axis (spiral motion). The exciter, which can adjust the eccentricity, produces a nonlinear three-dimensional motion, and the

material also produces the same motion similar to manual operation, so as to achieve the purpose of screening. More ideal

screening effect can be obtained by combining with screening accessories. It is suitable for materials with spherical,

cylindrical, flaky or even irregular shapes that are easy to block the screen and require precise screening.

Applicable Industries

Chemical industry: resin powder, pigment, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid,

Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, and urine, waste oil, food wastewater, wastewater processing, etc.

Abrasives, ceramic industry: alumina, quartz sand, mud, sprayed soil particles, etc.

Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

Paper industry: coating paint, clay mud, black and white liquid, waste liquid, papermaking liquid, wastewater recycling, etc.

Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid,

Chinese and Western medicine granules, etc.

Environmental protection: garbage, human and animal excrement, and urine, waste oil, food wastewater, wastewater processing, etc.

Technical parameters

Unit type | Layer | weight(KG) | Overall Size(MM) |

Y B S 1600 | 1 | 900 | 2000*1700*1180 |

2 | 1050 | 2000*1700*1300 | |

3 | 1300 | 2000*1700*1570 | |

Y B S 2000 | 1 | 1100 | 2370*2100*1230 |

2 | 1250 | 2360*2100*1870 | |

3 | 1400 | 2360*2100*1900 | |

Y B 2200 | 1 | 1300 | 2660*2300*1700 |

2 | 1450 | 2660*2300*1830 | |

3 | 1600 | 2660*2300*1960 |

Processing Procedure

customer visit

COMPANY PROFILE

Company Profile

About us

Xinxiang Tianfeng Vibration Machinery Co., Ltd. is a professional enterprise that produces and develops vibration, screening, and conveying equipment. The screening equipment produced by our company has advantages such as high screening efficiency, large processing capacity, and low noise. The company mainly focuses on three series of fine screening, conveying and feeding, and large screening machines, including the TS series three-dimensional rotary vibration screen, FYB series square swing screen, YBS series circular swing screen TLZS series linear vibrating screen, TS series vibrating straight row screen, ZKS series vacuum feeding machine, and other products are widely used in the building m aterials, chemical, medical, food, and mining industries, achieving rapid separation and filtration of various materials.

We constantly improve product quality and cost-effectiveness, obtaining many honors and patent certificates. Our professional production and sales team always prioritize customer needs and provide them with customized solutions.

We constantly improve product quality and cost-effectiveness, obtaining many honors and patent certificates. Our professional production and sales team always prioritize customer needs and provide them with customized solutions.

Xinxiang Tianfeng Vibrating Machinery Co., Ltd. (formerly Xinxiang Tianfeng Vibrating Machinery Factory) is a comprehensive

enterprise specializing in the research, development, manufacturing, and sales of mechanical equipment such as vibrating screen,

separation, crushing, and conveying for more than 30 years. The company mainly produces Vibrating screens, ultrasonic vibrating

screens, test screens, oscillating screens, linear screens, airflow screens, feeders, bucket elevators, conveying equipment, and

other mechanical equipment. This equipment features stable and reliable operation, simple operation, convenient maintenance, low

noise, low energy consumption, large output, and high precision; The screen mesh has the advantages of no blockage, no flying

powder, no liquid leakage, etc. The products are widely used in food, medicine, chemical industry, metallurgy, abrasives,

plastics, glass, paint, pollution control, and other industries, with high efficiency, large processing capacity, long service

life, and other characteristics.

enterprise specializing in the research, development, manufacturing, and sales of mechanical equipment such as vibrating screen,

separation, crushing, and conveying for more than 30 years. The company mainly produces Vibrating screens, ultrasonic vibrating

screens, test screens, oscillating screens, linear screens, airflow screens, feeders, bucket elevators, conveying equipment, and

other mechanical equipment. This equipment features stable and reliable operation, simple operation, convenient maintenance, low

noise, low energy consumption, large output, and high precision; The screen mesh has the advantages of no blockage, no flying

powder, no liquid leakage, etc. The products are widely used in food, medicine, chemical industry, metallurgy, abrasives,

plastics, glass, paint, pollution control, and other industries, with high efficiency, large processing capacity, long service

life, and other characteristics.

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers,

technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000

square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery

and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems

at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have

become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union

remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to

filter, which can ensure that we recommend the appropriate machine for you.

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers,

technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000

square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery

and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems

at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have

become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union

remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to

filter, which can ensure that we recommend the appropriate machine for you.

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices