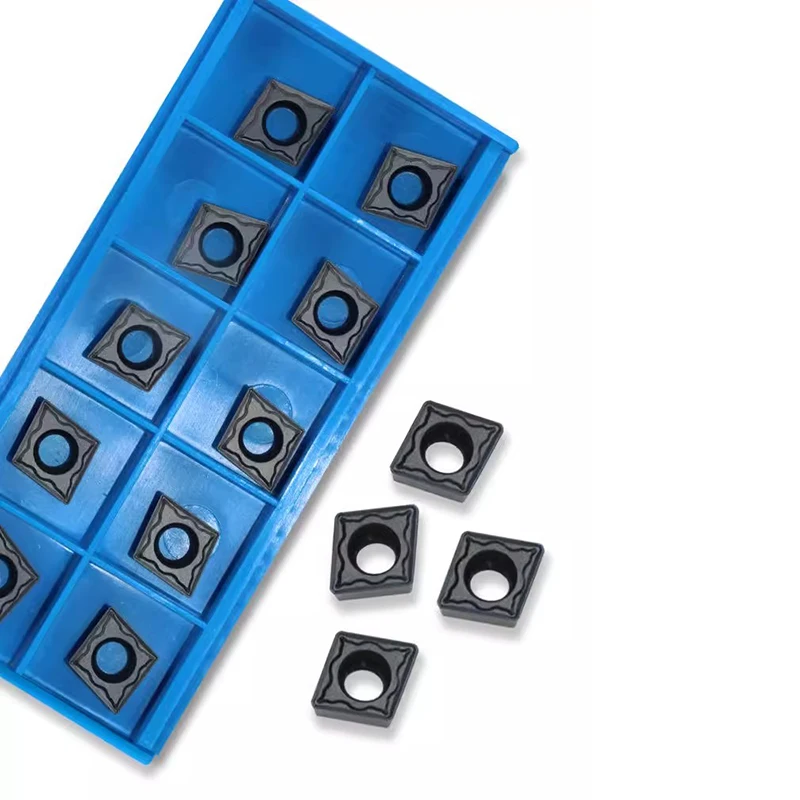

Kelite Manufacturer CNC Machining Tungsten Carbide Turning Insert TNMG WNMH LNMU MGMN for Hardened Material Finishing Machining

- Category: >>>

- Supplier: Zhuzhou Kelite Advanced Materials Co. Ltd.Zhuzhou Ltd.

Share on (1601241905971):

Product Overview

Description

Product features

Product Details

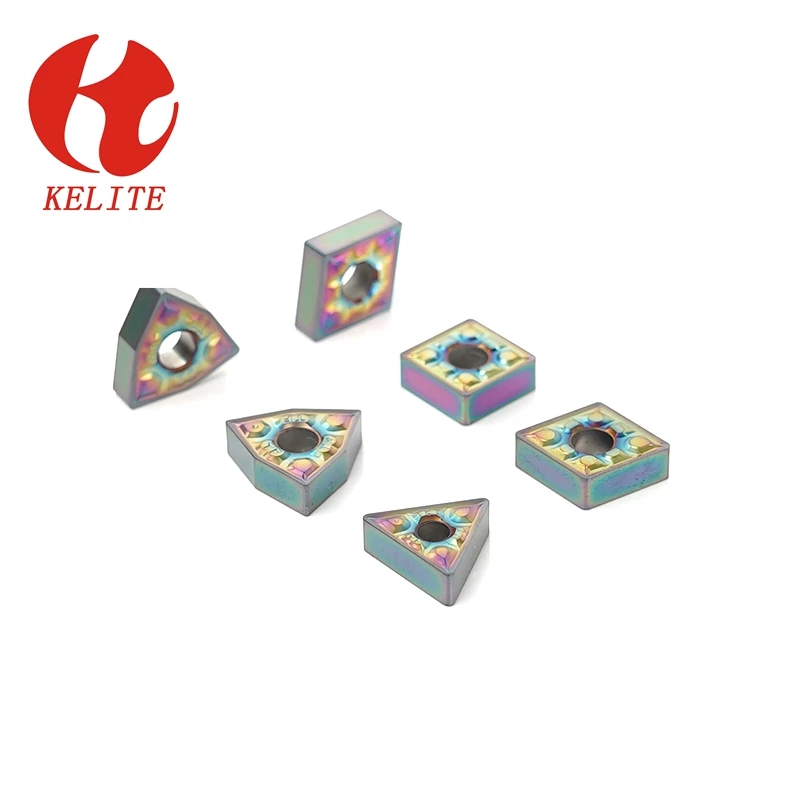

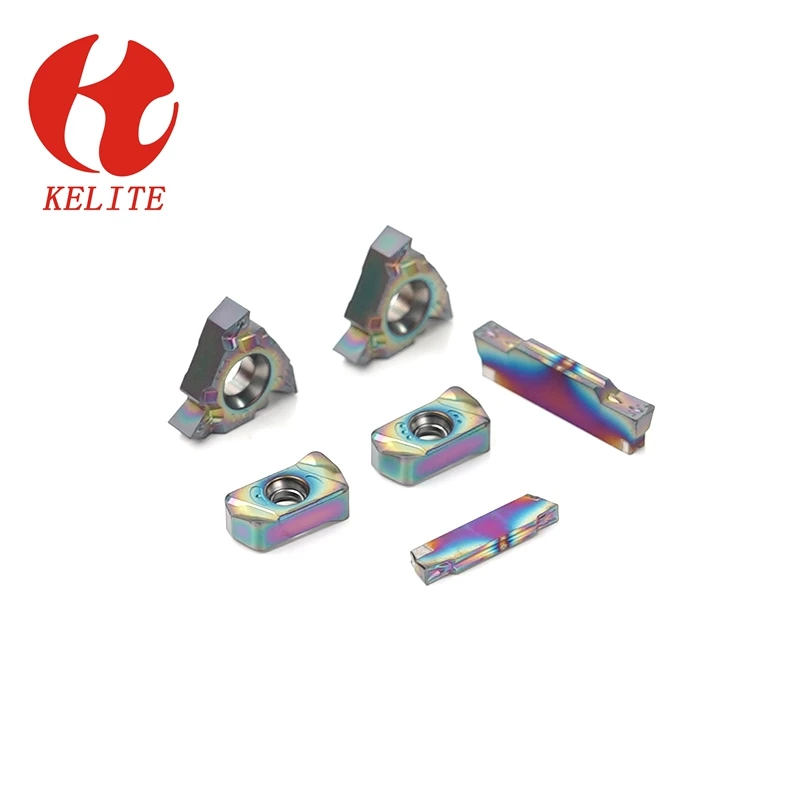

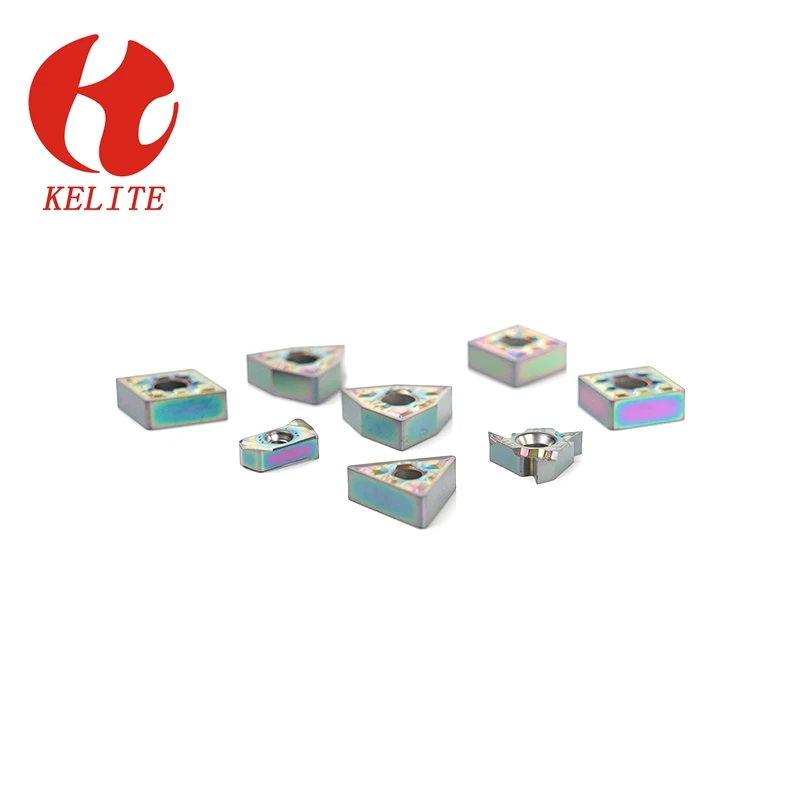

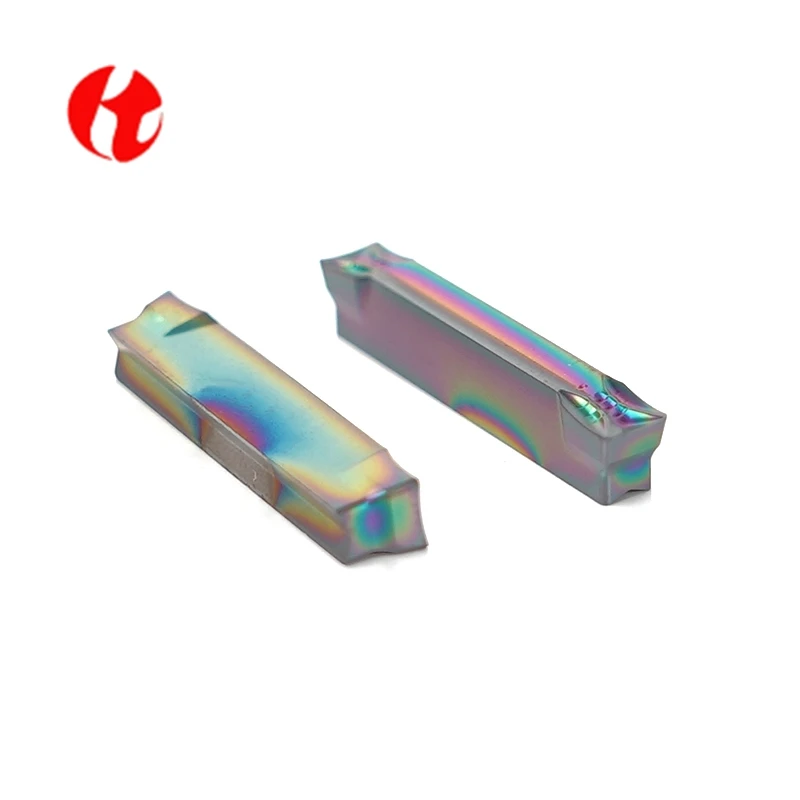

- Tungsten Carbide Insert CNC Lathe Machine Carbide Turning /Milling Inserts

- Production Name:

CNMG120408

WNMG080408

SNMG120408

VNMG160408

LNMU0303

MGMN-200/300/400-M

- Application: Metal Process for Hardened Materials

- New compound CVD coating grade

- Application: Metal Process for Hardened Materials

Outstanding wear resistence and intensity of inserts,suitable for cast iron during high speed, high feed process conditions,universal application not only for grey cast iron but also machining of nodular cast iron.

Grade Reference

Product use

Our products are widely used in the automotive industry, industrial

production, national defense technology, aerospace and other fields.

Our Advantage

--Efficiently solved build up edge,work hardening and other machining problems

--Cutting edge inclination designation is good to control chip flow direction and obtains excellent surface quality--sharp cutting edge, small cutting force

--good machining surface quality

--special chipbreaker design to keep cutting edge sharp and safe

--good anti impact resistance

--excellent tool life time

Experience、Product、Quality、Technology、Talents、Service、Customized

Company introduction

Located in the hometown of Tungsten Carbide of China, Zhuzhou Kerno Advanced Materials Co.Ltd has been specials in CNC carbide turning, milling, parting & grooving, threading, cermet, as well as heavy duty inserts, etc. Besides, we accepts customized special design products.

Our company was established in 2005 with a registered capital of 300 million yuan. We now have staff of 180 people and mainly export our productions to Europe, the Middle East, South American, Southeast Asia with good reputations. Having Kelite brand exclusive agent and distributors in many countries.

Our company has professional technology, a large number of talents and advanced production equipment. With first-class production technology and reliable product quality, we are highly recognized and approved by our partners, brand agent, wholesalers and end user.

With the core aim of“Consummate technical, Excellent quality, Satisfaction Service” and the principle of “Sci-tech innovation, Enhance Strength, Characteristic Management”, we will serve the customer better create more benefit for our customer.

We believe that we can achieve mutual benefits and win-win result with our customer through our continuous efforts and pursuit.

certificate

production process

Production and transportation

FAQ

Q: 1.Are you a trading company or manufacturer?

A: We are a professional manufacturer with more than 17 years experience in this field.

A: We are a professional manufacturer with more than 17 years experience in this field.

Q: 2.Can you produce Special Carbide Tools?

A: Yes, we can. We have our professional research and development team, so we can not only produce standard products but also customize products according to customers' blueprints and samples.

Q: 3.Can you provide samples?Is it free or extra?

A: Yes,we can offer free samples for testing as support, clients will need pay the samples deliver cost fee only.

Q: 4.What is the mode of transportation?

A: We usually send it to you by express, such as FEDEX,TNT,DHL, etc,if the customer needs, we can also send by air and sea.

Q: 5.How can I place the order?

A: Please send an inquiry sheet or contact us directly.

A: Yes, we can. We have our professional research and development team, so we can not only produce standard products but also customize products according to customers' blueprints and samples.

Q: 3.Can you provide samples?Is it free or extra?

A: Yes,we can offer free samples for testing as support, clients will need pay the samples deliver cost fee only.

Q: 4.What is the mode of transportation?

A: We usually send it to you by express, such as FEDEX,TNT,DHL, etc,if the customer needs, we can also send by air and sea.

Q: 5.How can I place the order?

A: Please send an inquiry sheet or contact us directly.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices