China Manufacturer P10/P20/P30/K10/K20/K30/K40 Tungsten Carbide Carbide Mining Tips

- Category: >>>

- Supplier: Zhuzhou Century Tool Co. Ltd.

Share on (1601242769147):

Product Overview

Description

Products Description

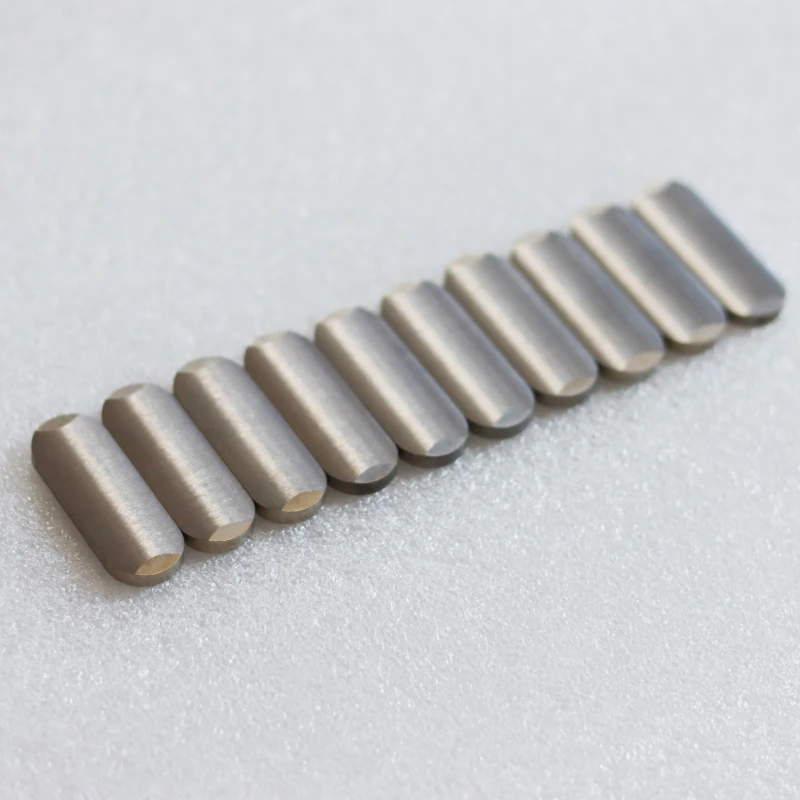

K10 Tungsten Carbide Brazed Tips In Stock

Overview

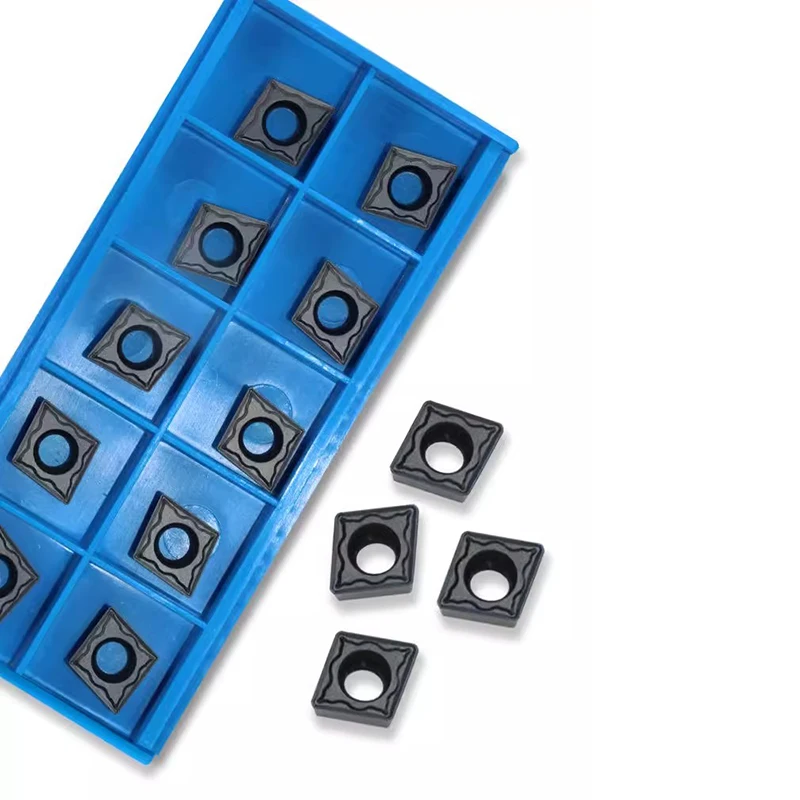

K10/K20/K30/P20/P30 cemented tungsten carbide tips brazed carbide tips for lathe turning tools

Zhuzhou Century Tool manufactures a comprehensive line of brazed tips in a wide range of grades for metalworking applications,

including grades for machining materials from steels and cast irons to nonferrous metal etc.

1. Product Application:

Brazed tools, also called carbide-tipped lathe tool bits and single-point brazed carbide-tipped

tools, are used for metal shaping on lathes. These single-point tools have a cutting edge at one

end that is a carbide tip brazed to a steel shaft. They come in multiple geometry styles for

different cutting applications

K10/K20/K30/P20/P30 cemented tungsten carbide tips brazed carbide tips for lathe turning tools

Zhuzhou Century Tool manufactures a comprehensive line of brazed tips in a wide range of grades for metalworking applications,

including grades for machining materials from steels and cast irons to nonferrous metal etc.

1. Product Application:

Brazed tools, also called carbide-tipped lathe tool bits and single-point brazed carbide-tipped

tools, are used for metal shaping on lathes. These single-point tools have a cutting edge at one

end that is a carbide tip brazed to a steel shaft. They come in multiple geometry styles for

different cutting applications

Grade | ISO Grade | Density g/cm3 | Hardness HRA | T.R.S>N/mm2 | Performances or recommended applications | |||||

Conventional grades | ||||||||||

YG6 | K20 | 14.85-15.05 | 90.5 | 1860 | Medium grain, for rough machining of non-ferrous metals | |||||

YG6A | K10 | 14.85-15.05 | 92.0 | 1600 | Fine grain, for drawing dies and woodworking tools | |||||

YG6X | K10 | 14.85-15.05 | 91.7 | 1800 | Fine grain, for cutting of non-ferrous metals | |||||

YG7 | K20 | 14.65-14.85 | 90.0 | 1900 | Medium grain with good wear-resistance and good impact- resistance | |||||

YG8 | K30 | 14.60-14.85 | 89.7 | 2060 | Medium grain, for drawing dies | |||||

YG10 | K40 | 14.25-14.55 | 88.0 | 2160 | Medium grain, for machining gray cast iron with a low hardness | |||||

YG11 | K40 | 14.30-14.50 | 87.5 | 2260 | Medium grain, for wear parts and mining tools | |||||

YG11C | 14.20-14.40 | 87 | 2260 | Coarse grain, for mining inserts | ||||||

Cutting steel class grade | ||||||||||

YT14 | P20 | 11.20-11.80 | 91.0 | 1550 | Suitable for semi-finishing and finishing machining of steel and cast steel, using a medium feed-rate | |||||

YT15 | P10 | 11.10-11.60 | 91.5 | 1500 | Suitable for semi-finishing and finishing machining of steel and cast steel and a medium feed-rate and a rather high cutting speed is to be recomme | |||||

Company Profile

Zhuzhou Century Tool Co., Ltd. is specialized in manufacturing and selling mechanical blades, various types of molds, and customized products. Our market covers more than 50 countries and regions worldwide.

With years of experience in production and marketing, advanced production equipment, as well as highly trained technical personnel and operators, Zhuzhou Century Tool Co., Ltd. specializes in producing high-quality hard alloy CNC blades, saw blades, cutting blades, mining tools, mold materials, rods, non-standard shaped high-end wear-resistant parts, and many other products that are widely used in metallurgy, machinery, geology, coal, petroleum, chemical, and other industries.

We provide Chinese and global users with cost-effective cutting machine tools and new materials and solutions for extreme working conditions. We sincerely appreciate the trust and support of our new and old customers over the years and solemnly promise to improve product quality and service.

With years of experience in production and marketing, advanced production equipment, as well as highly trained technical personnel and operators, Zhuzhou Century Tool Co., Ltd. specializes in producing high-quality hard alloy CNC blades, saw blades, cutting blades, mining tools, mold materials, rods, non-standard shaped high-end wear-resistant parts, and many other products that are widely used in metallurgy, machinery, geology, coal, petroleum, chemical, and other industries.

We provide Chinese and global users with cost-effective cutting machine tools and new materials and solutions for extreme working conditions. We sincerely appreciate the trust and support of our new and old customers over the years and solemnly promise to improve product quality and service.

Customer Photos

Exhibition

Certifications

FAQ

Q: Are you manufacturer or trading company?

A: We are professional manufacturer with more than 18 years experience in the field.Our affiliated trading company can also provide other brand products.

Q: Can you provide free samples?

A: We are glad to offer a few pieces of free samples. The international express fee is at your own charge.

Q: What is your MOQ?

A: For the ready to ship products, the minimum order quantity is the quantiy specified on the product page; for the bulk purchases or the customized products, our MOQ is 100pcs-1000pcs depending on the products you need.

Q: What is terms of payment?

A: Payment value <=USD1000,100% paid in advance. Otherwise, 30% T/T in advance, pay off the balance before shipping.

Q: What is the delivery way?

A: DHL, TNT, FEDEX,EMS, AIR FREIGHT, SEA FREIGHT etc.

Q: Do you offer OEM and ODM?

A: Yes, we have rich experience in OEM and ODM. We can engrave logo and specifications on the products. In addition, we can also do custom printing on the packaging plastic box.

A: We are professional manufacturer with more than 18 years experience in the field.Our affiliated trading company can also provide other brand products.

Q: Can you provide free samples?

A: We are glad to offer a few pieces of free samples. The international express fee is at your own charge.

Q: What is your MOQ?

A: For the ready to ship products, the minimum order quantity is the quantiy specified on the product page; for the bulk purchases or the customized products, our MOQ is 100pcs-1000pcs depending on the products you need.

Q: What is terms of payment?

A: Payment value <=USD1000,100% paid in advance. Otherwise, 30% T/T in advance, pay off the balance before shipping.

Q: What is the delivery way?

A: DHL, TNT, FEDEX,EMS, AIR FREIGHT, SEA FREIGHT etc.

Q: Do you offer OEM and ODM?

A: Yes, we have rich experience in OEM and ODM. We can engrave logo and specifications on the products. In addition, we can also do custom printing on the packaging plastic box.

Product packaging

We Recommend

New Arrivals

New products from manufacturers at wholesale prices