Advanced High Capacity Production Line for Instant Baby Cereal and Nutritional Powder with Extruder

- Category: >>>

- Supplier: Jinan Halo Machinery Co. Ltd.

Share on (1601245088228):

Product Overview

Description

Products Overview

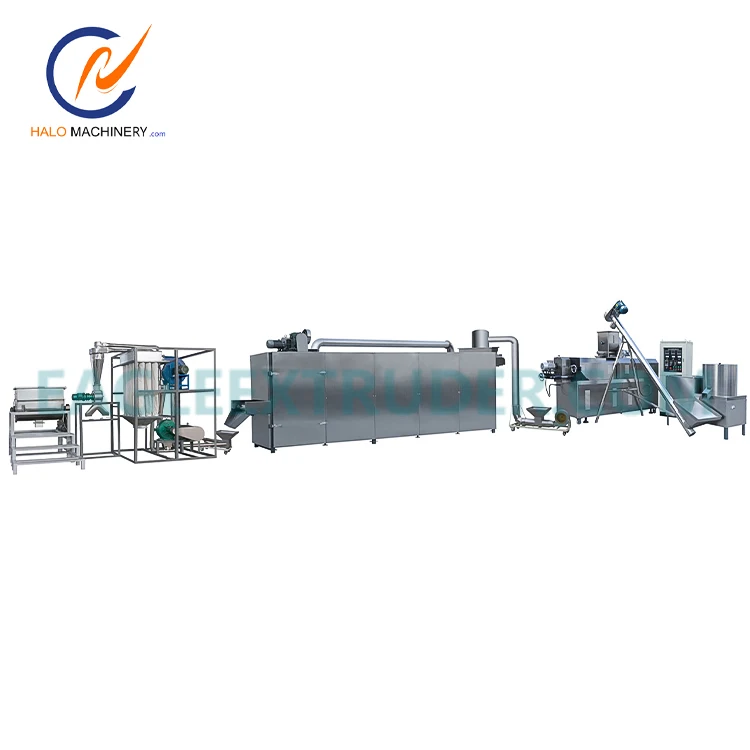

Twin screw extruder nutrition powder processing line for infant rice flour, sesame paste, and beans powder

Nutrition powder processing line is researched and developed by our company based on foreign advanced technology. The processing line transforms the method from raw grains cooking into high-temperature and high-pressure method, and then in extruded within five seconds. Meanwhile this processing line can denaturant the starch of the raw grains and be in favor of the absorption. It has a higher nutrition than the traditional craft. Many food manufacturers adopt this kind of food equipment at the present.

Firstly, the equipment that Nutrition Powder production is between 120-150kg/h.

Process flows: Raw material→mixing→extrusion puffing→air conveying→drying→crush→(packaging)

Equipment configuration: mixer→bulking machine→air conveying→three-layer roasting oven→crusher (packager)

Process flows: Raw material→mixing→extrusion puffing→air conveying→drying→crush→(packaging)

Equipment configuration: mixer→bulking machine→air conveying→three-layer roasting oven→crusher (packager)

Secondly, the equipment that Nutrition Powder production is between 200-260kg/h.

Process flows: Raw material→mixing→extrusion puffing→air conveying→drying→crush→(packaging)

Equipment configuration: mixer→bulking machine→air conveying→five-layer roasting oven→crusher (packager)

Process flows: Raw material→mixing→extrusion puffing→air conveying→drying→crush→(packaging)

Equipment configuration: mixer→bulking machine→air conveying→five-layer roasting oven→crusher (packager)

The above is supporting equipment, the equipment is cover an area of an area small, flow line length 12-14m, width 2.5m,

automation high strength, easy to operate and maintenance.

Remark: Crushing equipment belong to outsourcing machine, extra paid

automation high strength, easy to operate and maintenance.

Remark: Crushing equipment belong to outsourcing machine, extra paid

Extruder model | Main power | capacity | size | weight |

HL65 | 18kw/22kw | 120-150kg/h | 2.6x0.9x1.7m | 1200kg |

HL70 | 30kw/45kw | 200-260kg/h | 2.8x0.9x1.7m | 1300kg |

HL85 | 75kw/90kw | 400-600kg/h | 3.4x1.0x1.9m | 1800kg |

Contact information

Contact person: Ave Qi

Email: ava@halomachinery.com

mobile/whatsApp/wechat:15098955513

For more products, please go to:www.halomachinery.com、www.eagleextruder.com

For more products, please go to:www.halomachinery.com、www.eagleextruder.com

Delivery & Packing

Jinan Halo Machinery Co., Ltd located in Xujia insutrial zone, Tianqiao district, Jinan city, Shandong province, China.

We are professional manufacture of food extrusion production systems. The production process from technical drawing, welding,drilling, Lathe turning, measuring, testing in real production, whole procedures controls all equipments quality.

From ingredients preparation, mixing, extrusion cooking, additional cutting machines, dryers, fryers, flavor coating machines, packing machines, forms the different continuous production plants.

The production systems are for all kinds of expanded snacks, snack pellet, breakfast cereals, corn flakes, nutrition powder, pet food, fish pellet, modified starch, artificial rice, potato chips, bread crumbs and so on.

Timely after-sale service will always be offered. including related formular, lay-out drawing in factory, machines installation

and training. This will help clients to produce high quality produtcs all the time. We keep developing new products machine, and upgrade techniques to satisfy the requirements of all the clients.

Jinan Halo Machinery company machines have distributed the machines to many different countries, Vietnam, Indonesia,

Malaysia, Thailand, Lithuania, Italy, United states, Cheli, Peru , South Africa, Kenya, Libya etc.

And feel free to contact us!

Welcome to visit our factory!

We are professional manufacture of food extrusion production systems. The production process from technical drawing, welding,drilling, Lathe turning, measuring, testing in real production, whole procedures controls all equipments quality.

From ingredients preparation, mixing, extrusion cooking, additional cutting machines, dryers, fryers, flavor coating machines, packing machines, forms the different continuous production plants.

The production systems are for all kinds of expanded snacks, snack pellet, breakfast cereals, corn flakes, nutrition powder, pet food, fish pellet, modified starch, artificial rice, potato chips, bread crumbs and so on.

Timely after-sale service will always be offered. including related formular, lay-out drawing in factory, machines installation

and training. This will help clients to produce high quality produtcs all the time. We keep developing new products machine, and upgrade techniques to satisfy the requirements of all the clients.

Jinan Halo Machinery company machines have distributed the machines to many different countries, Vietnam, Indonesia,

Malaysia, Thailand, Lithuania, Italy, United states, Cheli, Peru , South Africa, Kenya, Libya etc.

And feel free to contact us!

Our Whatsapp: +8618660119608, wechat: atcn99 email is abc@halomachinery.com

Welcome to visit our factory!

FAQ

Q1: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q2: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Alibaba can get a discount.

Q3: Do you provide after-sale service?

A: Yes. The warranty peniod of our machines is one year, and we have a professional after-sale service team to promptly

and thoroughly solve your problems.

Q4: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment istallation, adjustment, and operation training. All of our engineers have passports.

Q5: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q2: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Alibaba can get a discount.

Q3: Do you provide after-sale service?

A: Yes. The warranty peniod of our machines is one year, and we have a professional after-sale service team to promptly

and thoroughly solve your problems.

Q4: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment istallation, adjustment, and operation training. All of our engineers have passports.

Q5: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices