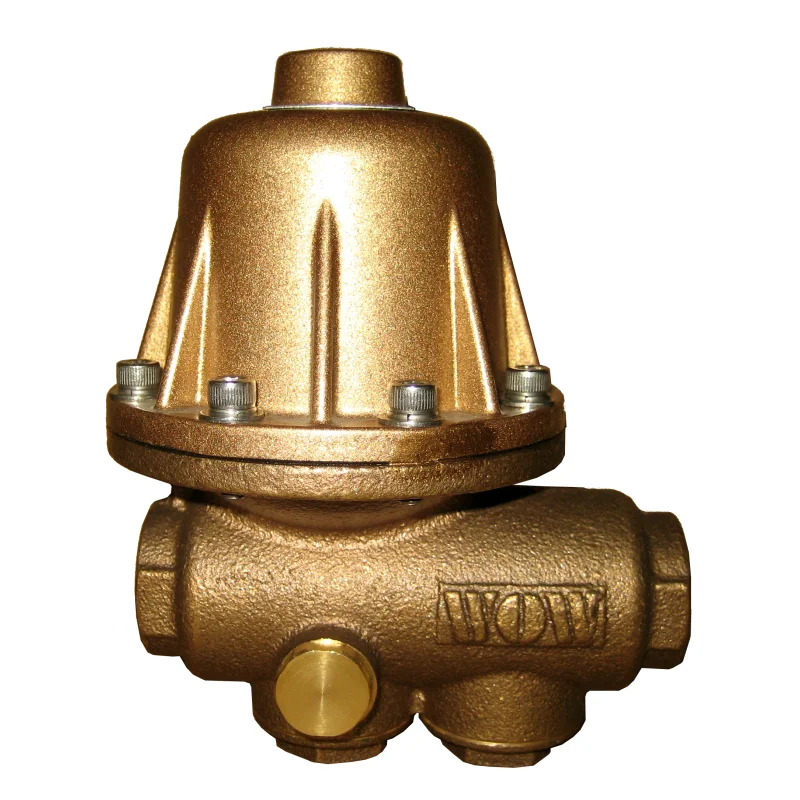

Custom Controlled Pilot Operated Water Pressure Reducing Valve Ductile Iron Prv Valve Manufacturer Price

- Category: >>>

- Supplier: RKS Fluid (Shenyang) Flow Control CompanyRKS Company

Share on (1601245317183):

Product Overview

Description

Product Paramenters

Pressure-reducing valve is also called pressure-stabilizing valve, pressure-reducing pressure-stabilizing valve.

No matter how the flow or pressure before the valve fluctuations and changes,The valve can be high pressure before the valve reduced to low pressure after the valve,and maintain stability; even if the valve no user water, can also maintain a stable outlet pressure (reduced static pressure) .

No matter how the flow or pressure before the valve fluctuations and changes,The valve can be high pressure before the valve reduced to low pressure after the valve,and maintain stability; even if the valve no user water, can also maintain a stable outlet pressure (reduced static pressure) .

Features

Fully bore globe pattern design, lowest head loss while fully openKeep stable working condition even the flow rate close to zero

High sensitive and strength fabric reinforced diaphragm

- 1000000 cycles test between fully close and open with working pressure

- 5 times of working pressure destructive test

Most components are machined by CNC

Fusion bonded epoxy coating process is based on GSK & WIS standard

High standard production test

- Seal test: Low pressure 0.5 bar

High pressure 1.1xPN+1 bar

- Shell test: 1.5xPN+1 bar

- Pressure modulated vibration: +/-0.2 bar

Data collected automatically 1000 times/sec, display with static or dynamic chart

Easy installation, operation and free maintenance

Different materials with WRAS/KTW/NSF/ACS certification to meet different market

Application Area

urban water supply and industrial,agricultural water transmission lines,etc.

Working Principle

pressure reducing valve is an accurate and pilot controlled valve ,It can be reduce a high inlet water pressure to a steady downstream pressure regardless of the inlet water pressure chanding.

urban water supply and industrial,agricultural water transmission lines,etc.

Working Principle

pressure reducing valve is an accurate and pilot controlled valve ,It can be reduce a high inlet water pressure to a steady downstream pressure regardless of the inlet water pressure chanding.

Size | NPS1½-NPS40(DN40-DN1200) |

Working Medium | Water or Fueling |

Temperature | 0°C~70°C |

Material | Ductile Iron/Stainless Steel/Cast Steel/Bronze/Aluminum Alloy |

DN | L | H | H1 | DN | L | H | H1 |

40 | 230 | 139 | 85 | 250 | 730 | 476 | 205 |

50 | 230 | 139 | 85 | 300 | 850 | 526 | 232 |

65 | 290 | 159 | 95 | 350 | 980 | 585 | 262 |

80 | 310 | 179 | 102 | 400 | 1100 | 624 | 292 |

100 | 350 | 214 | 112 | 500 | 1250 | 720 | 360 |

125 | 400 | 278 | 127 | 600 | 1450 | 835 | 425 |

150 | 480 | 333 | 145 | 800 | 1850 | 1110 | 515 |

200 | 600 | 407 | 172 | 1000 | 2250 | 1350 | 630 |

Recommend Products

Company Profile

RKSfluid was founded in 1997, RKSfluid features a modern production workshop for both foundry and machining, research & development center, and quality inspection center. The manufacturing facilities include advanced CNC machining centers, professional processing cells, broad spectrum welding equipment, automatic assembling and coating lines. we have built a professional team for design, research & development. Our production and sales covering 3 business areas: Fluid Control Products, Technology & Environmental Protection Products, Health Care Medical Products. The new testing center has been listed as a public service platform testing center in Liaoning Province, it has received a high degree of recognition by industry peers and experts. Become the standard GB of the chinese valve reference unit, to participate in the development of the relevant valve industry standards. In order to accelerate the expansion of overseas business and resources integration, and to support the success of RKSfluid sales in the USA, we have created a R&D and service center in Houston, Texas. Our product design standards cover: GB, ISO, German standard, and American Standard, approved by TUV for CE and ADWO-2000, ISO9001, TS, PED, WRC, KTW in china.

Exhibition

Certifications

FAQ

Q1: How long is the delivery time? A1: Generally it's 5-10 days we have stock. Or it's 15-90 days depend on different product and quantity. | ||||||

Q2: What about the payment term? A2: T/T 30% deposit, balance payment after finished production before shipment. Or as discussed. | ||||||

Q3: Can I have a sample order? A3: Yes, we agree sample order, mixed different models is also acceptable. | ||||||

Q4: What's your MOQ? A4: We can support 1 pc order. Welcome you to check our quality. | ||||||

Q5: What's your quality inspection? Do you test all your goods before delivery? A5: Yes, 100% test. It integrates R&D, casting, production, processing, painting, assembly, testing, sales and after-sales service, and strict quality requirements, according to GB, ASME, API, DIN standard, and we have gained ISO9001;2008, CE, and TUV certification. | ||||||

Q6: Could I customize special request valve or new design products? A6: We have own R&D team and more than 70 researchers and engineers. Can give you the best support on quality management and techniques, meet your different needs. | ||||||

Q7: How does your factory do regarding quality control? A7: Quality is priority. Valve always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001;2008, CE, TUV, authentication. | ||||||

Contact Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices