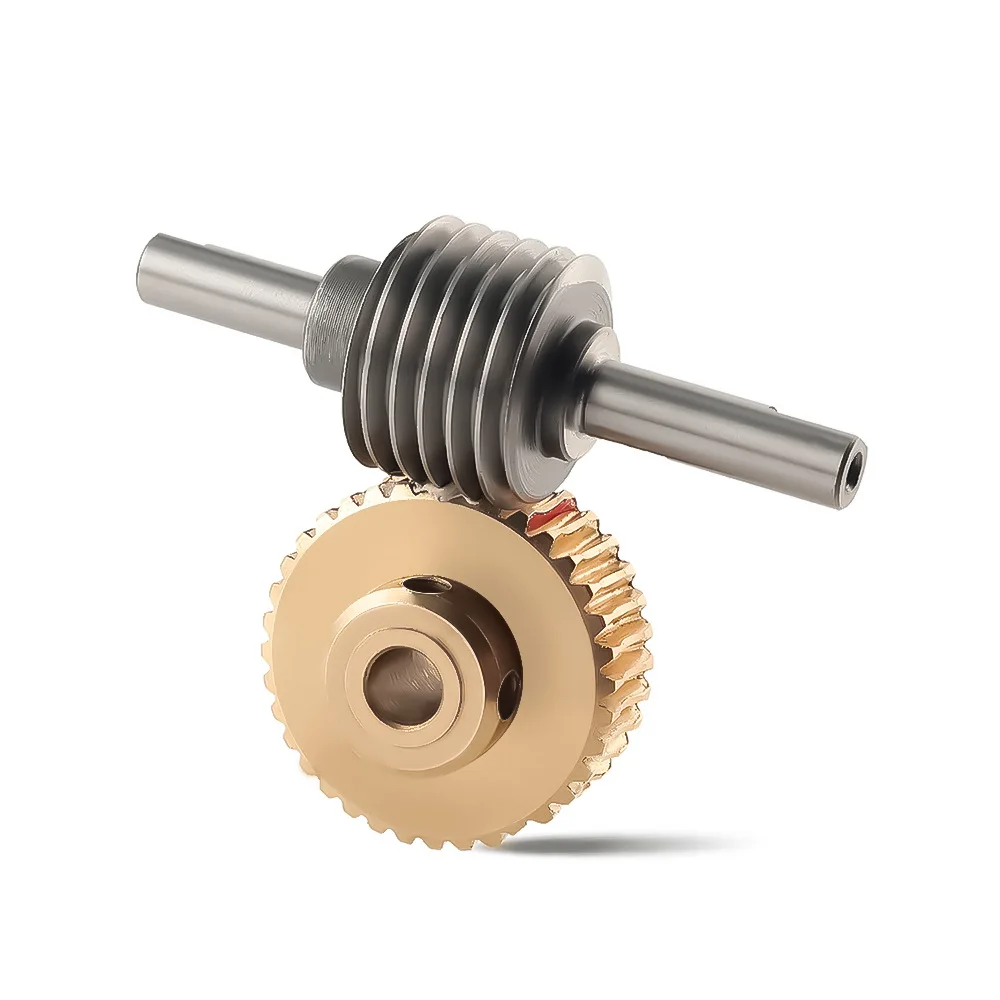

Double Rotator Stainless Steel Roller Gear Metal Worm Gear Motor Clamp Lifting Platform Measurement

- Category: >>>

- Supplier: Dalian Ruici Industry Co. Ltd.Dalian Ltd.

Share on (1601246044938):

Product Overview

Description

Product Description

1. Milling method

Milling method is the most commonly used method in worm processing. Its principle is to use a milling tool to mill along the spiral path of the worm. The advantages of this method are high processing efficiency, high processing accuracy, and good surface finish, but it requires special processing centers and tools.

Milling method is the most commonly used method in worm processing. Its principle is to use a milling tool to mill along the spiral path of the worm. The advantages of this method are high processing efficiency, high processing accuracy, and good surface finish, but it requires special processing centers and tools.

Production Process

2. Rolling method

Rolling method is a more popular method in worm processing. Its principle is to use a roller to roll along the spiral path of the worm to form a worm. The advantages of this method are high processing efficiency, good surface finish, and not easy to produce thermal deformation, but the requirements for processing equipment are high.

Rolling method is a more popular method in worm processing. Its principle is to use a roller to roll along the spiral path of the worm to form a worm. The advantages of this method are high processing efficiency, good surface finish, and not easy to produce thermal deformation, but the requirements for processing equipment are high.

3. Precision forming method

Precision forming method is a relatively new worm processing method. Its principle is to use a CNC cutting machine to process an elliptical worm precursor, and then undergo precision forming to finally form a worm. The advantages of this method are high processing accuracy, good surface finish, and low cost, but it requires higher processing technology and manual forming.

Precision forming method is a relatively new worm processing method. Its principle is to use a CNC cutting machine to process an elliptical worm precursor, and then undergo precision forming to finally form a worm. The advantages of this method are high processing accuracy, good surface finish, and low cost, but it requires higher processing technology and manual forming.

Specification

item | value |

Place of Origin | China |

Liaoning | |

Brand Name | OEM |

Condition | New |

Product name | worm wheel,worm gear,gear |

Application | Transmission |

Material | Steel Alloy |

Packing | Carton |

Size | Customized Size |

Type | Components |

Processing | Post Heat Treatment Polishing |

Packing & Delivery

carton box /as per the customer

Company Profile

Dalian Ruici Industry Co., Ltd. is a leading manufacturer and exporter of high profile casting, machining, molds and assembly products, etc. Featuring optimum combination of price and performance, our products are widely used on valves, water pumps, speed reducers, ejectors and automobiles, etc. With over two decades of perseverance and dedication in production and total quality management, we have established a long-term loyal customer base in North America, Europe, East Asia, and Mid East.

Our core competitiveness edge lies in total customer solutions. By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Our core competitiveness edge lies in total customer solutions. By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

FAQ

1. who are we?

We are based in Liaoning, China, start from 2005,sell to Western Europe(60.00%),North America(20.00%),Oceania(10.00%),Southeast Asia(10.00%),South Asia(0.00%),Eastern Asia(0.00%),South America(0.00%),Southern Europe(0.00%),Central America(0.00%),Northern Europe(0.00%),Africa(0.00%),Eastern Europe(0.00%),Domestic Market(0.00%),Mid East(0.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Castings, Forgings, Stampings, Valve Parts, CNC Machining

4. why should you buy from us not from other suppliers?

Over 20 years export experience on casting and machining business, advanced production(CNC and machining center) and inspection equipments (CMM), fully quality control system(ISO 9001:2008), perfect after-sales service. Main market Germany, Japan, USA.....

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,DDP,DDU;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Japanese

We are based in Liaoning, China, start from 2005,sell to Western Europe(60.00%),North America(20.00%),Oceania(10.00%),Southeast Asia(10.00%),South Asia(0.00%),Eastern Asia(0.00%),South America(0.00%),Southern Europe(0.00%),Central America(0.00%),Northern Europe(0.00%),Africa(0.00%),Eastern Europe(0.00%),Domestic Market(0.00%),Mid East(0.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Castings, Forgings, Stampings, Valve Parts, CNC Machining

4. why should you buy from us not from other suppliers?

Over 20 years export experience on casting and machining business, advanced production(CNC and machining center) and inspection equipments (CMM), fully quality control system(ISO 9001:2008), perfect after-sales service. Main market Germany, Japan, USA.....

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,DDP,DDU;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Japanese

We Recommend

New Arrivals

New products from manufacturers at wholesale prices