PFC2P PFC4 PF7M PF7MF PF41 PF50 PF51 PF52 ZDS PF09 M2.5 M3 M3.5 M4 M5 M6 Knurling Captive Panel Fastener Spring Loaded Screw

- Category: >>>

- Supplier: Shenzhen Dongtuo Hardware Products Co. Ltd.Shenzhen Ltd.

Share on (1601246442391):

Product Overview

Description

Product Paramenter

Item Name | PFC2P PFC4 PF7M PF7MF PF41 PF50 PF51 PF52 ZDS PF09 M2.5 M3 M3.5 M4 M5 M6 Knurling Captive Panel Fastener Spring Loaded Screw |

Available Material | 1. Stainless steel: 201,303,304,316,410 2. Carbon steel: C1006,C1010,C1018,C1022,C1035K,C1045 3. Copper: H65,H62,H65,H68 4.Aluminum: 5056, 6061, 6062, 7075 5. According to customer demand 5.Ta2 TC4 GR2 GR5 Titanium alloy |

Grade | 8.8grade 10,9grade 12.9grade |

Specification | Size: M3-M36, Length 6~300mm |

Supply non-standard and special size according to customer's requirement | |

Standard | GB, DIN, ISO, ANSI/ASTM, BS, BSW, JIS etc |

Surface Treatment | Polishing, Milling, Anodised Gold, Blue, Green, Purple , Black,rainbow etc |

Features | Light Weight, Excellent Resistance, Anti-Corrosion, Excellent Mechanical Strength etc. |

Applications | Equipment accessories: airplane, ship, bicycle, motorcycle, auto, wheelchair, sports, anchor, weapon, etc. |

Test and Quality | 1. ISO 9001:2008 2. Mechanical properties test. 3. Inspection ensure the materials meet destructive and non-destructive test according to industry and customer specification. |

Payment | T/T, L/C, Westener Union, MoneyGram, Paypal |

Product Description

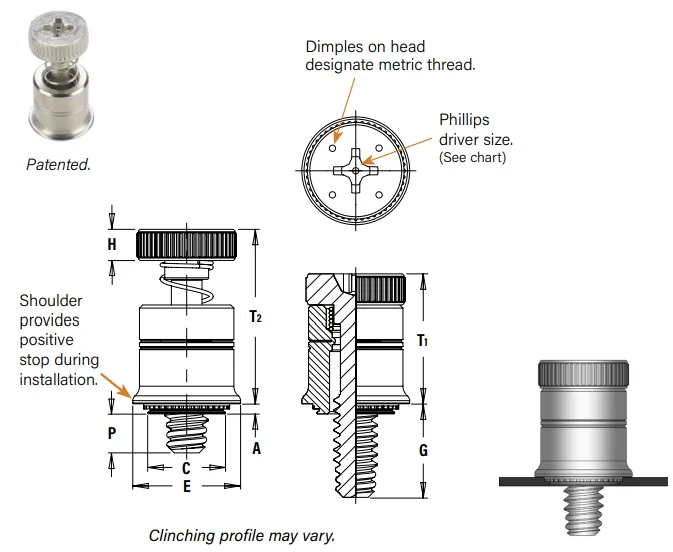

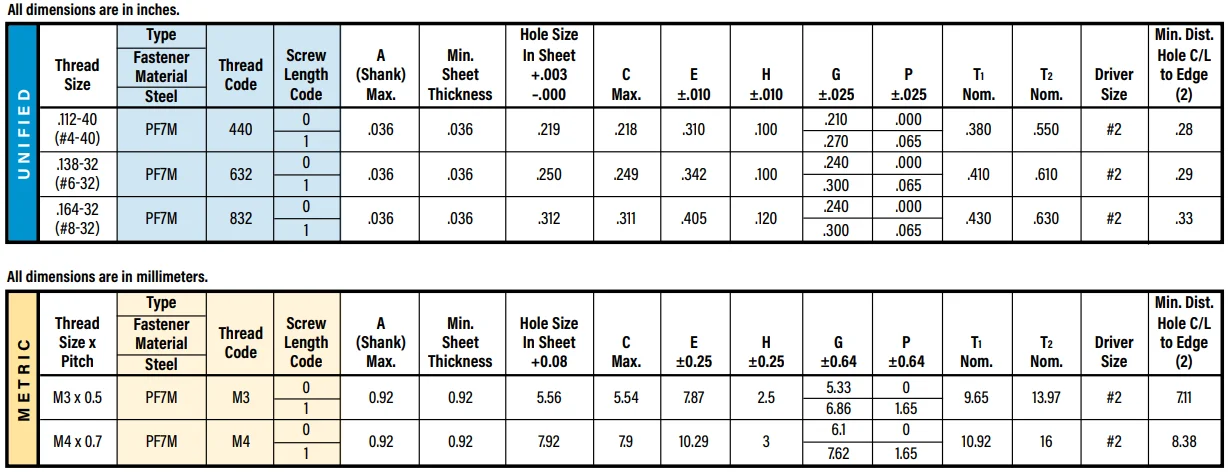

PF7M And PF7MF |

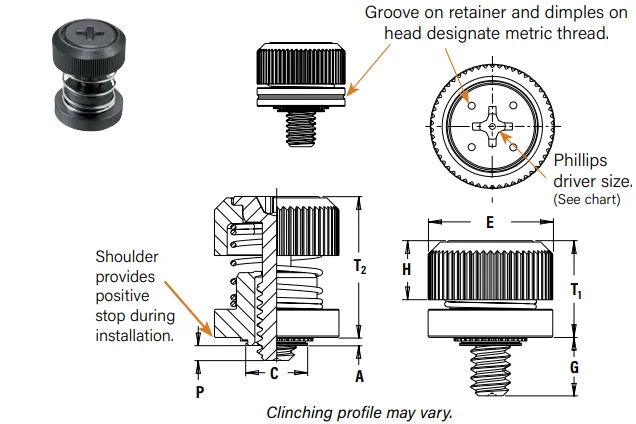

PF50 PF51 PF52 PF60 PF61 PF62 |

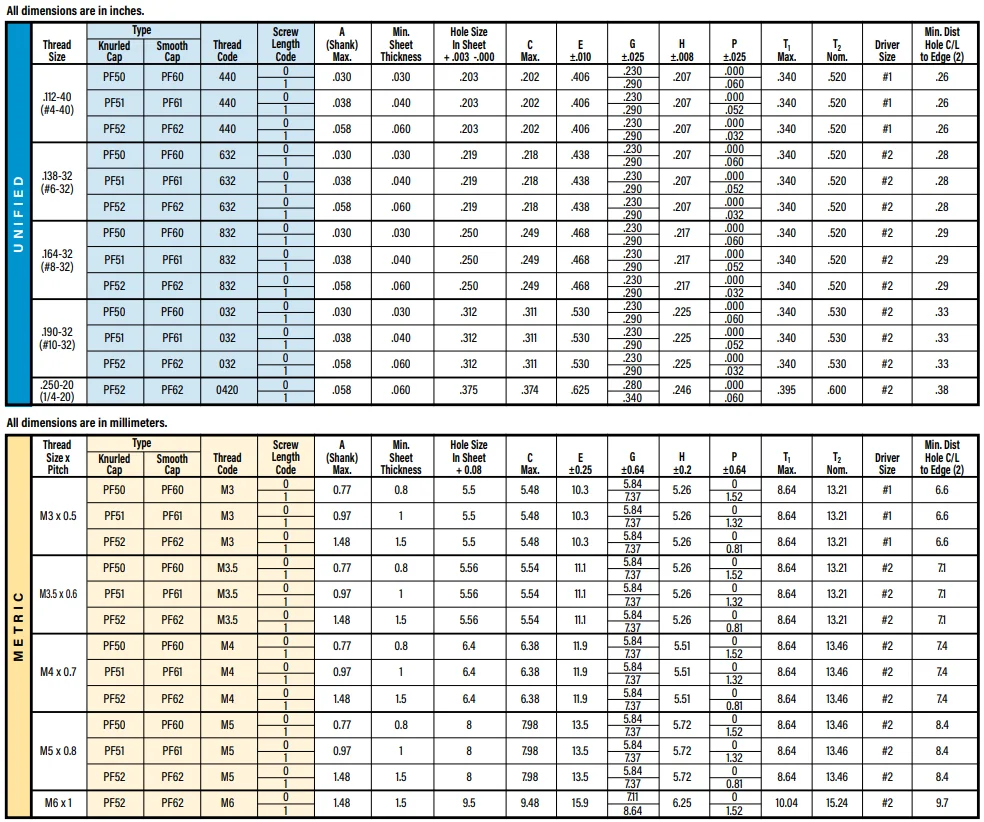

PFC2P |

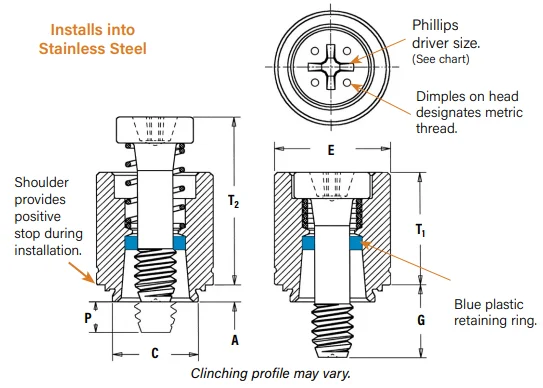

PFC4 |

Company Profile

Shenzhen Dongtuo Hardware Products Co., Ltd. is a company that undertakes various types of hardware stamping parts and mechanical processing of non-standard parts. The average age of the company's management team is 35 years old. The company has a professional production team that integrates design, production, and sales, with strong technical strength, advanced production equipment, and complete testing equipment. The company has a production workshop covering an area of 3000 square meters, mainly producing various types of fasteners such as spring screws, riveting nuts, riveting bolts, riveting screw sheets, core pulling rivets, and rivet nuts. |

The company currently owns more than 30 large-scale presses, including 200 ton hydraulic stretching machines, 160 ton presses, 125 ton presses, 100 ton presses, and 63 ton presses (40 ton to 6.3 ton) 52 polishing equipment and 6 heat treatment equipment. There are three precision machining production lines for instrument machinery, including mold processing equipment (lathes, washing machines, planers, and drilling machines), various types of instrument lathes, CNC machine tools, and dozens of production equipment. We provide assistance for technical personnel to design and develop product molds themselves, as well as several CNC computer spring machines imported from Germany. We are currently cooperating with well-known domestic and foreign enterprises and high-quality purchasers, producing products in more than ten fields such as construction hardware, mechanical hardware, daily hardware, automotive manufacturing, hydraulic systems, and iron gardening. We have developed product types of tens of thousands,and have rich experience in stamping and forging manufacturing. Our product stamping parts are mainly sold in Europe, America,Japan, and other regions. |

Shenzhen Dongtuo Hardware Products Co., Ltd. adheres to the principle of "becoming a first-class enterprise and creating a well-known brand", continuously introduces various excellent professional and technical talents, optimizes and improves management and operation mechanisms, and is dedicated to serving customers both domestically and internationally. |

Looking back on the past 20 years, our company has put customers first and quality first. We hope to do better in the future and serve you, which is a win-win situation. |

Our factory | CNC equipment | Automatic lathe |

Automatic tapping machine | Stamping process workshop | Cold heading screw workshop |

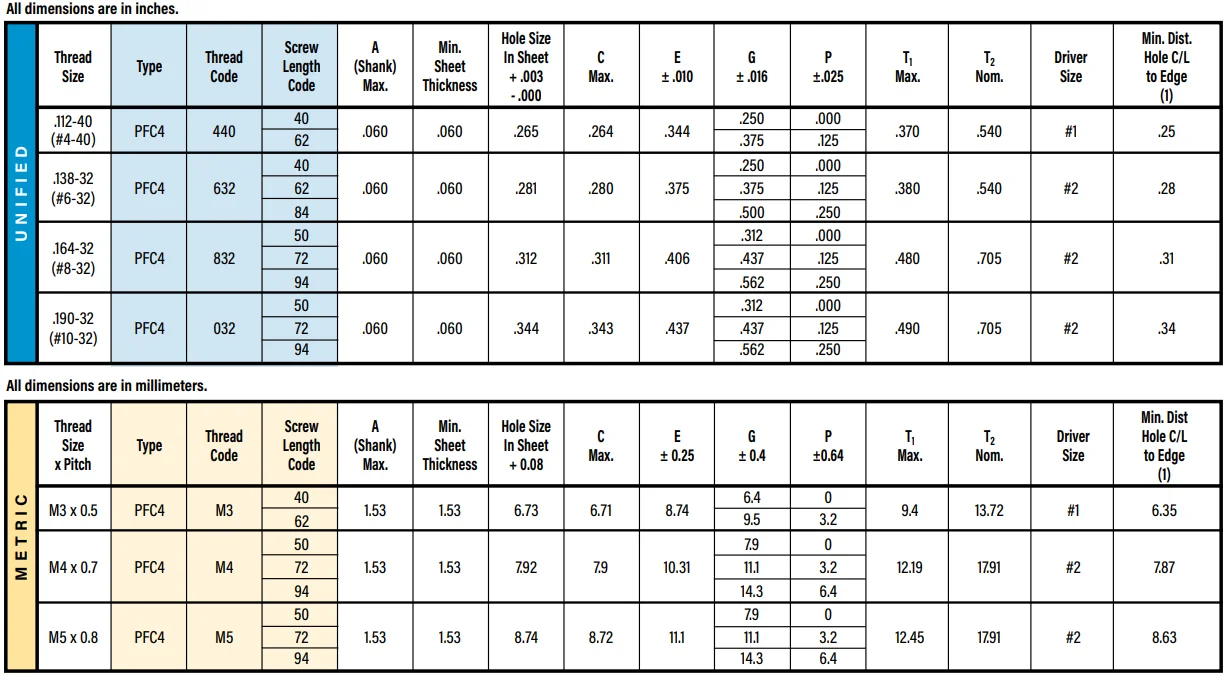

Measuring projector | Optical screening instrument | Salt spray testing equipment |

FAQ Q1: What is your main product? A: Our main products are hardware parts, including fasteners, connectors, bolts, nuts, screws, rivets... Products are widely used in furniture, automotive, industrial, heavy industry, medical and other industries Q2: How to customize (OEM/ODM)? A: We are a professional manufacturer with 20 years of experience. We accept OEM, ODM customization. We can customize according to your needs, and guarantee you a competitive price and quality. Q3: What is your delivery time? A: For all custom screw orders, 15-25 working days after receiving your payment, please contact customer service for details. Q4: How to choose the most suitable product? Answer: As long as you tell us what kind of test you need to do and the required specifications, our professional team will give you the best advice. Q5: What is the lead time for sampling? A: 1-7 days depends on different products. For items that need to open a new mold, the delivery time is 10-15 days. Q6: How do you control the quality? In the production process, each process is checked at any time to ensure that the size and appearance of the production meet the customer's requirements. Can provide online video real-time feedback on production progress and size inspection. Q7: How should I order and pay? A7: According to T/T, 100% samples are arranged in order: For production, 30% of the deposit is paid by T/T before the production arrangement, and the balance is paid before shipment. |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices