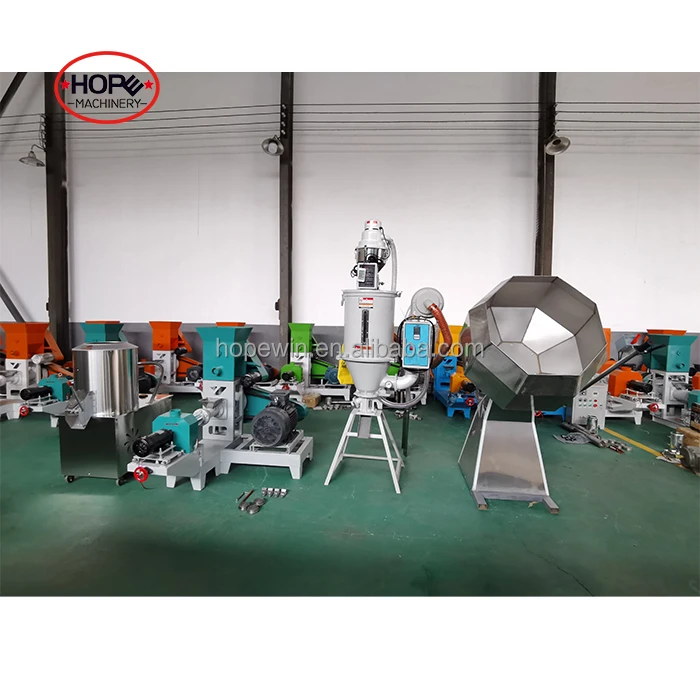

Sinking Floating fish feed extruder production line

- Category: >>>

- Supplier: Shandong Hope Machinery Co. Ltd.

Share on (1601247364495):

Product Overview

Description

Product Description

Floating fish feed extruder machine is a kind of fish feed pellet machinery ,it is suitable for small and medium feed process factory and aquaculture farm. It can produce high-grade feed pellets which is suitable variety aquatic ,such as fish, catfish, crab, shrimps,cat,dog etc.Single screw extruder is much cheaper price and easy operation than twin screw extruder.

Floating Fish Feed Extruder Machine Working Principle:

During the extrusion process, raw materials would be processed via high temperature, high moisture and high pressure, so at the moment that feed pellets are extruded from die hole, the stress drops sharply and the water content in feed emits from liquid state to gas state, resulting in extruded fish feed.Fish feed production requires higher degree of gelatinization and water stability, starch gelatinization can kill salmonella and other various harmful bacteria,also strengthen adhesive property of feed pellets under high temperature , which ensure that pellets with smooth and clean appearance are not easy to be eroded by water.It’s not only promotes the water stability of fish feed but also improves the palatability and digestibility of feed. Moreover, the usage of floating fish feed extruder machine can make sure fish and shrimp have longer ingestion time, and prevent water pollution caused by feed pellets.

Enlarged Feed Inlet

Large feed port design

Easy feed raw materials

Built-in T-shaped mixing roller

Easy feed raw materials

Built-in T-shaped mixing roller

Heater Band Device For Extrusion

Equipped with multiple heating sheets

Rapid heating, good extrusion effect

Rapid heating, good extrusion effect

Cutting Device

Equipped with independent cutter motor, Sliding table design, smooth cutting

Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Home Use, Retail, Food & Beverage Shops, fish food factory

Fish feed and pet feed mold

Can produce a variety of shapes of feed pellets

Can produce a variety of shapes of feed pellets

Features of Floating Fish Feed Pellet

1.High protein content and low carbohydrate. The protein content of livestock feed is often less than 20%, while that of aquaculture feed is always 30%-40, and thereinto green turtle and eel feed protein content is up to 65%-70%.

2. Small pellet size. Due to short intestines and stomach and other physiological properties of aquatic animal, the fineness of pulverization of aquatic feed should be smaller than poultry feed in order to accelerate digest and absorption.For example, when producing eel feed or prawn feed, the particle size should reach 80-120 meshes.

3. Single screw extruder extruded feed pellet structure is compact, with higher cohesiveness and water resistance. For instance, prawn feed requires the water stability of pellet feed up to 2 hours.

4. Easy digest and absorb,fish feed extruder machine can produce sinking aqua livestock feed. By eliminating most of toxins, anti-nutritional factors and urine antitrypsin enzyme contained in raw materials, feeds are easy for animals to digest and absorption, to improve digestion and utilization of nutrients.it’s helpful to protein transform and Gelatinized starch, easy for fish and animal to digest and absorb.

1.High protein content and low carbohydrate. The protein content of livestock feed is often less than 20%, while that of aquaculture feed is always 30%-40, and thereinto green turtle and eel feed protein content is up to 65%-70%.

2. Small pellet size. Due to short intestines and stomach and other physiological properties of aquatic animal, the fineness of pulverization of aquatic feed should be smaller than poultry feed in order to accelerate digest and absorption.For example, when producing eel feed or prawn feed, the particle size should reach 80-120 meshes.

3. Single screw extruder extruded feed pellet structure is compact, with higher cohesiveness and water resistance. For instance, prawn feed requires the water stability of pellet feed up to 2 hours.

4. Easy digest and absorb,fish feed extruder machine can produce sinking aqua livestock feed. By eliminating most of toxins, anti-nutritional factors and urine antitrypsin enzyme contained in raw materials, feeds are easy for animals to digest and absorption, to improve digestion and utilization of nutrients.it’s helpful to protein transform and Gelatinized starch, easy for fish and animal to digest and absorb.

Production process

1. Put the raw materials into the mixer according to the formula and mix them evenly

2. Put the mixed ingredients into the feed extruder to puff out pellets

3. Put the matured particles in the dryer for drying

4. Put the dried particles into the seasoning machine for oiling and seasoning

1. Put the raw materials into the mixer according to the formula and mix them evenly

2. Put the mixed ingredients into the feed extruder to puff out pellets

3. Put the matured particles in the dryer for drying

4. Put the dried particles into the seasoning machine for oiling and seasoning

Advantages of floating fish feed extruder machine

Adjustable speed pelletizing motor with discharging transmission to meet production needs

The spiral design of the heating device discharges more uniformly, and the operation is safer and more stable.

The feed port is designed to feed uniformly and have a larger capacity to prevent jamming. Simple and convenient operation

The control system adopts an independent control electric box, no exposed wires, and easy to operate

Adjustable speed pelletizing motor with discharging transmission to meet production needs

The spiral design of the heating device discharges more uniformly, and the operation is safer and more stable.

The feed port is designed to feed uniformly and have a larger capacity to prevent jamming. Simple and convenient operation

1.Floating fish feed machine can make pellet from diameter 1mm-12mm just by changing the mould.

2.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

3.High temperature and high pressure cooking process can wipe out the salmonellosis and bacterial infections and also makes the pellets easily to digest.

4.The cutting device can be adjusted to make pellets of different length

5.The extruder design isunique, structure is simple, easy to install,easy to disassemble,easy to operate.

6.The floating time can be controlled by the puffing degree adjustment

7.The finished pellets can keep floating for 3-15 hours without pollution to water.

8.Floating fish feed machine can make pellet from dia.1.0mm-20mm just by changing the mold.

9.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

10.The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

2.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

3.High temperature and high pressure cooking process can wipe out the salmonellosis and bacterial infections and also makes the pellets easily to digest.

4.The cutting device can be adjusted to make pellets of different length

5.The extruder design isunique, structure is simple, easy to install,easy to disassemble,easy to operate.

6.The floating time can be controlled by the puffing degree adjustment

7.The finished pellets can keep floating for 3-15 hours without pollution to water.

8.Floating fish feed machine can make pellet from dia.1.0mm-20mm just by changing the mold.

9.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

10.The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

How To Choose Fish Feed Extruder Machine ?

----------------------------------------------------------------------------------------------------------------------------------

Aquaculture is currently the fastest developing food producing sector in the world, now accounts for almost 50% of the world’s food fish,it is regarded as an income generating activity for the farmer.

Fish is a rich source of vitamins, minerals, essential fatty acids and high-quality protein. Farmed fish is a critical food

source. It is reported that small- and medium-scale commercial farms, mainly growing fish for home consumption, accounts for 70%-80% of global aquaculture production.However, fish feed makes fish farming expensive as fish feed account for at least 60% of the total cost of production. Hence many farmers tend to buy a fish feed making machine to produce own fish feed, lowering the cost.

Feeding young fish or shrimp with big pellets will cause swallow problem. Meanwhile,feeding big fish with small pellets is not economical.If you have fish farm for adult grass carp, 8mm feed pellets will be good choice for your fish feeding.

In addition to pellet size, we should also pay attention to the feed pellet type. There are hard feed pellets, soft feed pellets and extruded feed pellets. Choose the wrong size or type of feed not only increase the feed waste, affect the fish health, but also can cause water pollution. Therefore, it is very important to choose the right fish feed manufacturing machine for making the most appropriate size and type of fish feed.

The user also need choice machine according to your farm scale.In a word, it is better to choose dry type fish feed extruder for small or medium scale feed production,select the wet type one for medium or large scale fish farm or feed factory, and the difference between these two is that the wet type with large capacity and better quality pellet.

----------------------------------------------------------------------------------------------------------------------------------

Aquaculture is currently the fastest developing food producing sector in the world, now accounts for almost 50% of the world’s food fish,it is regarded as an income generating activity for the farmer.

Fish is a rich source of vitamins, minerals, essential fatty acids and high-quality protein. Farmed fish is a critical food

source. It is reported that small- and medium-scale commercial farms, mainly growing fish for home consumption, accounts for 70%-80% of global aquaculture production.However, fish feed makes fish farming expensive as fish feed account for at least 60% of the total cost of production. Hence many farmers tend to buy a fish feed making machine to produce own fish feed, lowering the cost.

Feeding young fish or shrimp with big pellets will cause swallow problem. Meanwhile,feeding big fish with small pellets is not economical.If you have fish farm for adult grass carp, 8mm feed pellets will be good choice for your fish feeding.

In addition to pellet size, we should also pay attention to the feed pellet type. There are hard feed pellets, soft feed pellets and extruded feed pellets. Choose the wrong size or type of feed not only increase the feed waste, affect the fish health, but also can cause water pollution. Therefore, it is very important to choose the right fish feed manufacturing machine for making the most appropriate size and type of fish feed.

The user also need choice machine according to your farm scale.In a word, it is better to choose dry type fish feed extruder for small or medium scale feed production,select the wet type one for medium or large scale fish farm or feed factory, and the difference between these two is that the wet type with large capacity and better quality pellet.

Product Paramenters

Model | Main Motor Power(KW) | Capacity (T/H) | Feeding Power (KW) | Screw Dia. (MM) | Cutting Power (KW) | Size(MM) | Weight(KG) |

DGP40C | 3/5.5 | 0.03-0.04 | 0.4 | φ40 | 0.4 | 1400*1050*1250 | 280 |

DGP50C | 11 | 0.06-0.08 | 0.4 | φ50 | 0.4 | 1450*1100*1250 | 320 |

DGP60C | 15 | 0.12-0.15 | 0.4 | φ60 | 0.4 | 1460*1140*1250 | 360 |

DGP70B | 18.5 | 0.18-0.2 | 0.4 | φ70 | 0.4 | 1650*1400*1300 | 600 |

DGP80B | 22 | 0.2-0.30 | 0.6 | φ80 | 0.6 | 1800*1450*1300 | 730 |

DGP90B | 37 | 0.30-0.4 | 0.6 | φ90 | 0.8 | 2100*1450*1350 | 950 |

DGP120B | 55 | 0.5-0.6 | 1.1 | φ120 | 2.2 | 2400*1950*1600 | 1700 |

DGP135B | 75 | 0.7-0.8 | 1.1 | φ133 | 2.2 | 2550*2050*1650 | 1900 |

DGP160B | 90 | 1-1.2 | 1.5 | φ155 | 3.0 | 2900*2650*1800 | 3600 |

DGP200B | 132 | 1.8-2.0 | 1.5 | φ195 | 4.0 | 3000*2850*1900 | 4300 |

Detailed Images

Packaging & Shipping

Company Introduction

Shandong Hope Machinery Co., LTD. founded in 2003, is located in the industrial park of Taohuashan High-tech Zone, Zhangqiu,Shandong Province, covering an area of about 35,000 square meters. As a national high-tech enterprise,

Hope Machinery is a leading provider of pelleting system integration in the world. It is committed to customizing whole-plant personalized solutions for customers, such as bio-fermented feed, floating & siking fish feed, aquatic feed, pet dog cat feed manufacturing. biomass pellet fuel, bio-organic fertilizer, corn deep processing, ready-mix powder and so on.

We follows the ideals of "Customers Oriented, Common Development". We are making great efforts to offer high quality wood processing machines, biomass energy grinding machines and organic fertilizer machines. We can make coal and biomass into energy.

Our company has an excellent after-sales service team with advanced technology and rich experience. The after-sales service system is perfect. Our workers can reach any place of China in 24 hours except very remote places. We can resolve your problems at the first time.

We firmly believe that in the guidance of "Customer Oriented, Common Development". The future of pellets machinery will be glorious and resplendent.

Hope Machinery is a leading provider of pelleting system integration in the world. It is committed to customizing whole-plant personalized solutions for customers, such as bio-fermented feed, floating & siking fish feed, aquatic feed, pet dog cat feed manufacturing. biomass pellet fuel, bio-organic fertilizer, corn deep processing, ready-mix powder and so on.

We follows the ideals of "Customers Oriented, Common Development". We are making great efforts to offer high quality wood processing machines, biomass energy grinding machines and organic fertilizer machines. We can make coal and biomass into energy.

Our company has an excellent after-sales service team with advanced technology and rich experience. The after-sales service system is perfect. Our workers can reach any place of China in 24 hours except very remote places. We can resolve your problems at the first time.

We firmly believe that in the guidance of "Customer Oriented, Common Development". The future of pellets machinery will be glorious and resplendent.

Why Choose Us

Our factory has more than 23 years of experience in the industry, the product quality is reliable, timely service. With strong design and development ability, it can provide users with the whole process service from scheme design to use.

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, the factory has a certain market in the domestic and international network, externally oriented, domestic-based, set of technology, production, industry and trade integrated enterprise.

Q: How long is your delivery time?

A: Generally it is 15 days. we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shipment after inspection.

Q: What's the warranty?

A: Warranty is one year. Core component like motor, bearings is five years.

A: We are a manufacturer, the factory has a certain market in the domestic and international network, externally oriented, domestic-based, set of technology, production, industry and trade integrated enterprise.

Q: How long is your delivery time?

A: Generally it is 15 days. we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shipment after inspection.

Q: What's the warranty?

A: Warranty is one year. Core component like motor, bearings is five years.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices