Quote to make the mold, Make custom injection molding tool injection mould

- Category: >>>

- Supplier: Zetar Industry Co. LimitedZetar Limited

Share on (1601250014189):

Product Overview

Description

ABS-348 Lustran

ABS-HMG47MD SABIC

GPPS-2678 MED STYRON

GPPS-666D STYRON Trinseo

HDPE-HE9601-PH Bormed

HDPE-HE9601-PH Bormed RECYCLED

LDPE-PCG09 SABIC

PC+ABS-HC1204HF SABIC

PC-2858 Makrolon

PC-HP1HF LEXAN...

ABS-348 Lustran

ABS-757F CHEIMEI

ABS-PA737 CHEIMEI

ABS-PA757 CHEIMEI

AS SAN-82TR LG

GPPS-666D STYRON Trinseo

HDPE-9001 TAISOX

HDPE-B53-35H-011 INEOS Polyolefins

HDPE-HHM5502BN MARLEX

HDPE-M200056 Sabic...

HIPS-PH-88E CHEIMEI

PA66+13GF-70G13HS1L DUPOND

POM-100P DUPOND

POM-M90 DURACON

PP-1120 YUNGSOX

PPA+50GF-GV-5H GRIVORY EMS

PPS+40GF-A604WR Torelina TORAY

PP-T30S FUNDE

TPU-255D Texin

TPU-45A 12P000 BASF

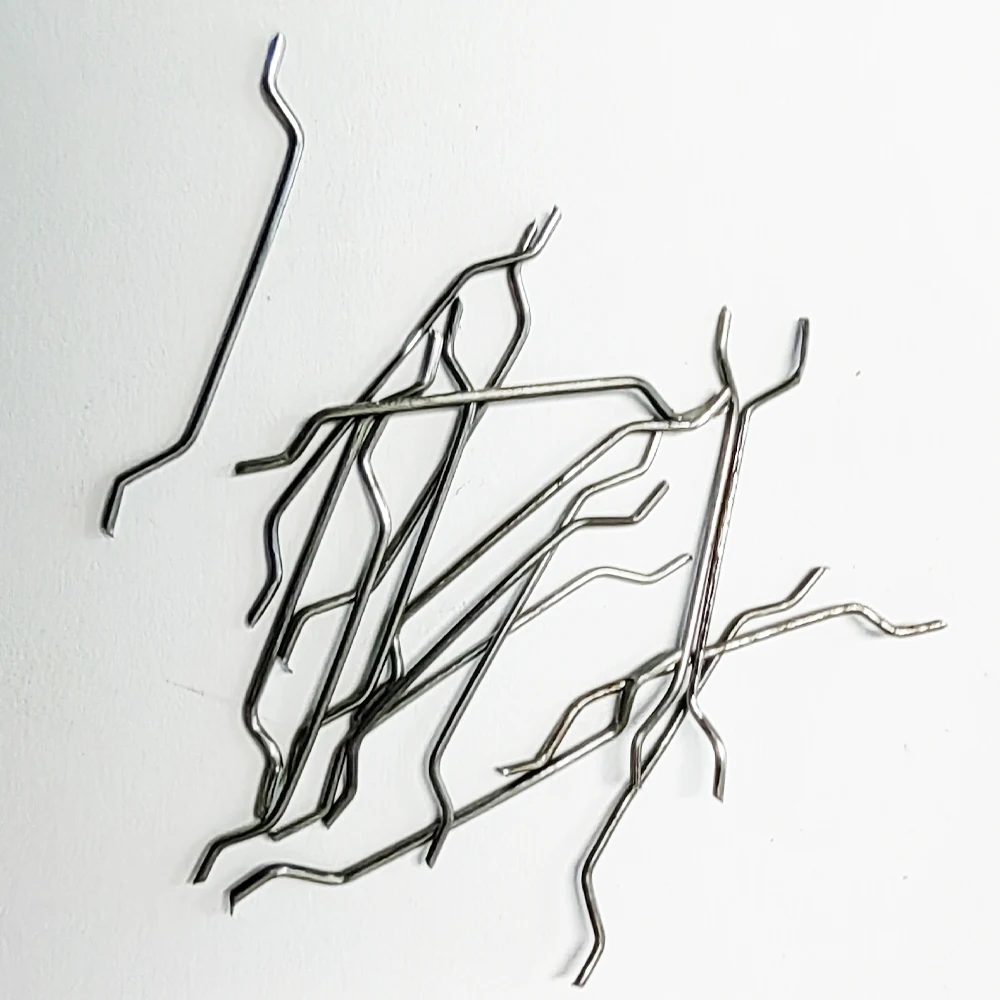

Shanghai Zetar Industry Co., Limited has been focus on plastic injection mold and molding serivce ever since its fundation.

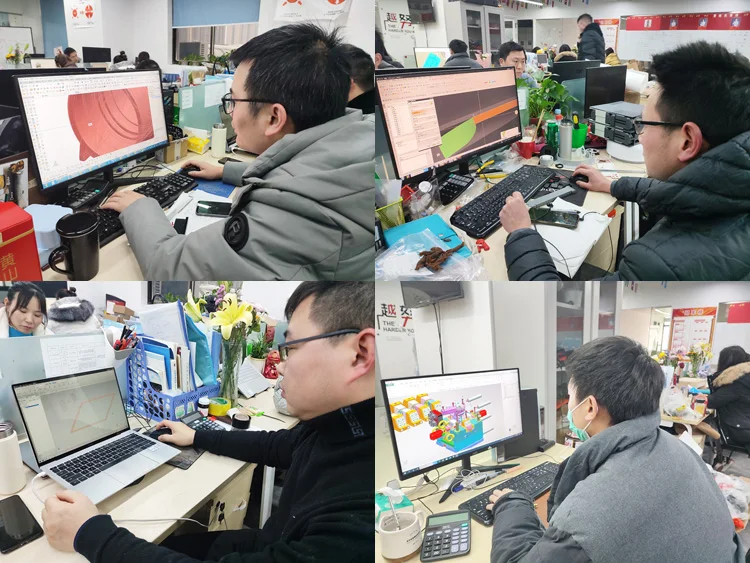

We have professional engineering team which has more than 5 engineers who is good at plastic injection mold design, plastic injection molding process as well as metal stamping works.

Our company has In-house tooling shop- fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Meanwhile 90 ton - 1100 ton injection molding machines 20 sets,30000 square feet injection molding room including 250 square feet M7 class clean room.We can produce parts from 0.01pound to 13 pounds.

Sales team are thoughtful and good at understanding your idea and points, where help to make your work much eaiser. 24*7 comminication service, whenever you need us, we are here for you.

Morever, we stand at your position, practice strict quality inspection procedures.

Your satifaction is what we pursue.

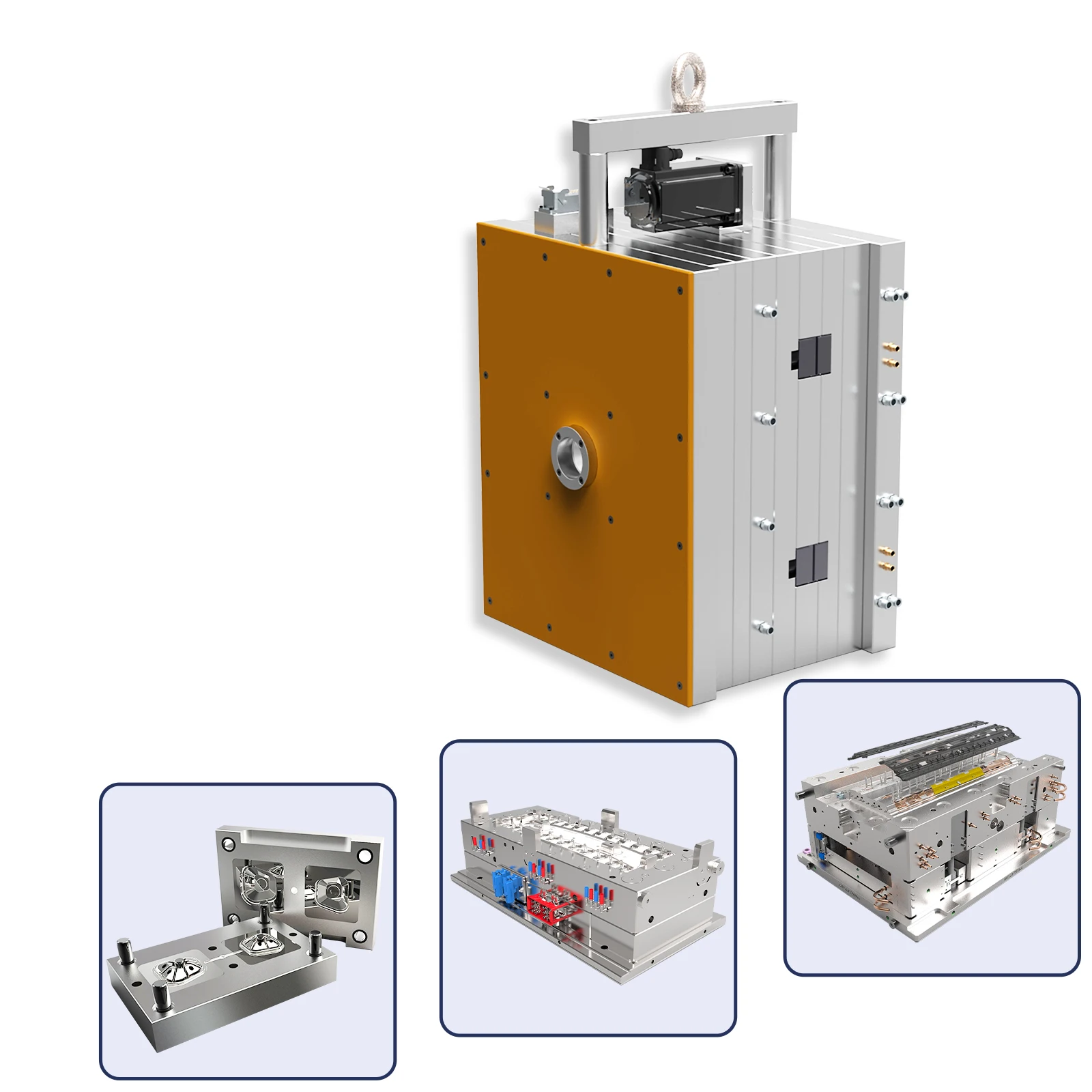

Mold Design

We will communicate&exchange the opinion with customers during Mold Deisgn

Mold Making

Start to manufacture, we will sent photos to show tooling process.

Provide the sample

Once the sample finish,we will send the sample to customer confirm

Mass Production

After customer confirmed the sample, we will start mass production plastic products.

Assembly

We Also Provide Assembly Service For Our Customer.

Painting&Coating

We can provide coating and rubber coating service for your customers.

Printing

We Also Provide Silk Screen Printing, Pad Printing, Heat Transfer Print Service.

Packaging Box

We also make the packaging box as customer request.

We are a manufacturer as you can see our workshop as above.

2. What kind of trade terms can you do?

EX-WORKS,FOB,CIF,DDP DDU

3. What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy

of B/L. We accept T/T

4. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

5. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).

We Recommend

New Arrivals

New products from manufacturers at wholesale prices