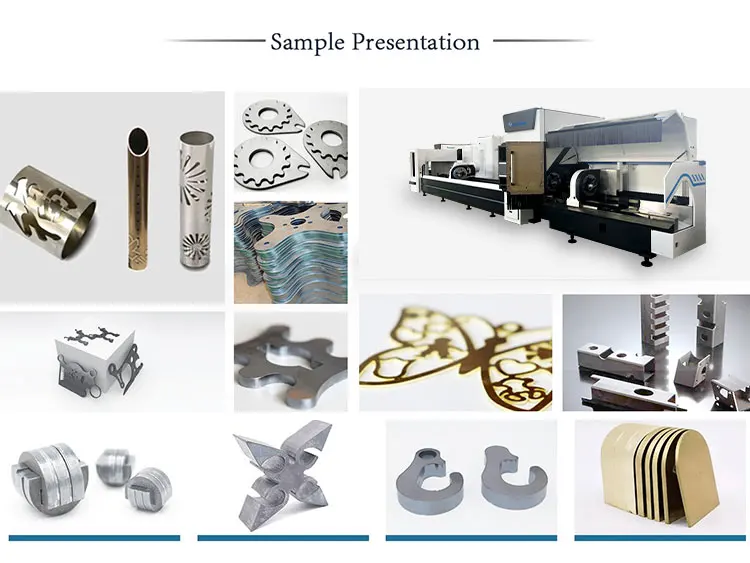

Prima Power Genius Laser Cutting Machine 4020

$13,550.00-15,800.00

Share on (1601250371666):

Model | TubeLINE-6020BK | TubeLINE-7028BK |

Power | 3000W/6000W | 3000W/6000W |

Processing range | φ12-200mm □12-140mm | φ12-280mm □12-200mm |

Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

Repositioning Accuracy | ±0.05mm | ±0.05mm |

Max no-load running speed | 100m/min | 100m/min |

Max idle speed | 100r/min | 100r/min |

Max mass of single pipe | 250kg | 250kg |

Feeding dimensions | ≤3000mm | ≤3000mm |

New products from manufacturers at wholesale prices