Commercial high speed chopping and mixing machine onion ginger garlic minced meat dumpling stuffing chopping machine

- Category: >>>

- Supplier: Shandong Shengkang Shengshi Intelligent Equipment Machinery Co. Ltd.

Share on (1601250808246):

Product Overview

Description

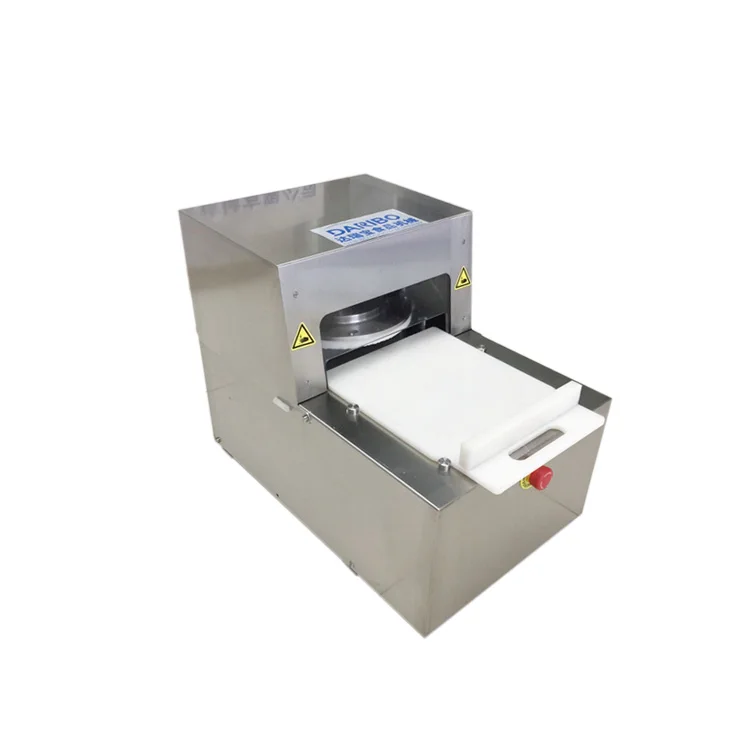

Our multifunctional bowl cutter machine using chopping knife high-speed rotation cutting effect, meat, meat, fat and other main raw materials fine cut into meat or meat mud, at the same time other raw materials such as water, auxiliary materials mixed together into uniform milk.

The high speed rotation of the cutting knife can shorten the running time, reduce the calorific value of the material, and maintain the natural color, elasticity, yield and product warranty of the filling.

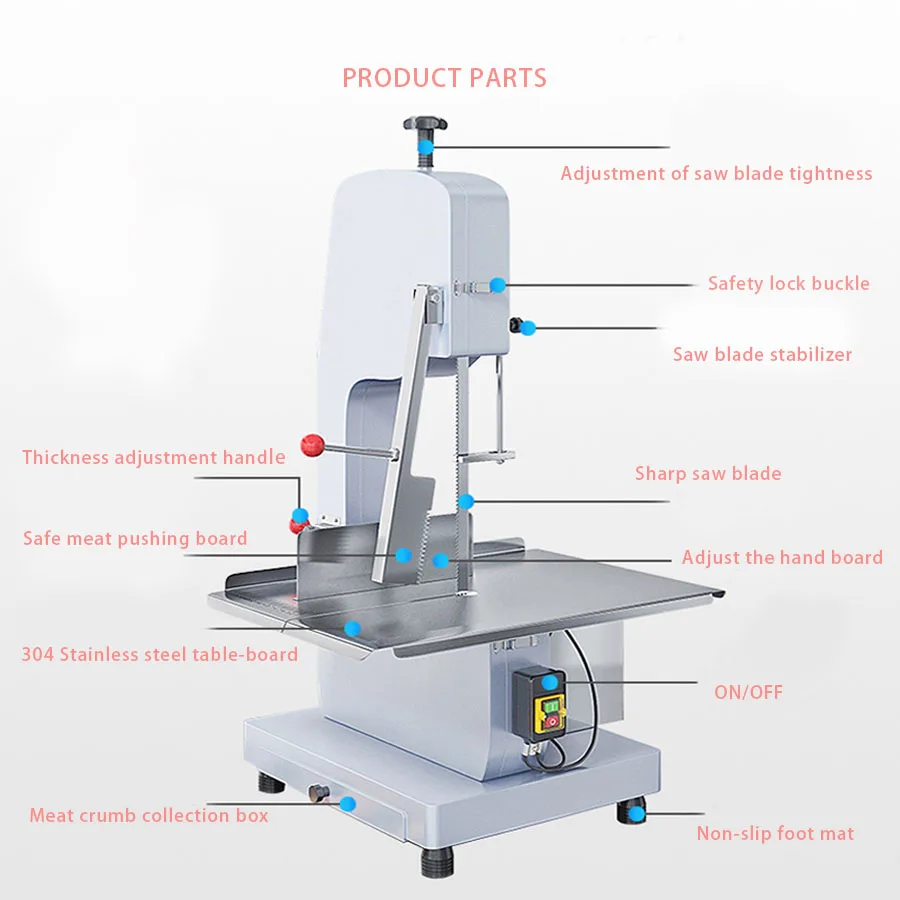

1.All of the vegetable meat chopper/ cutter is made of food grade SUS304 (bowl, pot, rack, sheel etc.). The structure is compact and beautiful,easy to clean, it is in accordance with food hygiene standards

2.The main parts are processed by CNC machining center to ensure accuracy.

3.The knives are made of 3CR13,sharp and durable,smooth running in high speed.

4.Sweden imported SKF bearing,the imported dual-bearing spindle tandem installation,ensure knife shaft group has good concentricity.

5.The good quality copper core motors comply with the European standard , strong anti-overload.

6.Maximum speed can reach 4500 rpm, which can greatly improve the emulsifying effect , so that the processed meat product production rate is higher.

7.The reasonable design of knife speed,pot speed,clearance between knifepoint and pot makes each part achieve the best combination. In such way,the finished meat product has the characteristics of good fineness,low temperature rise,short cutting time.

8.Frequency conversion technology can also be adopted on request, high range knife speed adjustment, high efficiency and energy saving.

2.The main parts are processed by CNC machining center to ensure accuracy.

3.The knives are made of 3CR13,sharp and durable,smooth running in high speed.

4.Sweden imported SKF bearing,the imported dual-bearing spindle tandem installation,ensure knife shaft group has good concentricity.

5.The good quality copper core motors comply with the European standard , strong anti-overload.

6.Maximum speed can reach 4500 rpm, which can greatly improve the emulsifying effect , so that the processed meat product production rate is higher.

7.The reasonable design of knife speed,pot speed,clearance between knifepoint and pot makes each part achieve the best combination. In such way,the finished meat product has the characteristics of good fineness,low temperature rise,short cutting time.

8.Frequency conversion technology can also be adopted on request, high range knife speed adjustment, high efficiency and energy saving.

3 pieces Blade knives shape

3 pieces Blade knives shape

6 pieces Blade knives shape

Model | SKC-20 | SKC-40 | SKC-80 | SKC-125 |

Power | 2.55KW | 4.75KW | 13.17KW | 21.85KW |

Capacity | 20KG | 30KG | 80KG | 100KG |

voltage | 220V/380V | 380V | 380V | 380V |

Cutting speed(rpm) | 1430/2850 | 1430/2880 | 1880/3600 | 1800/3600 |

Dimensions | 780*600*850mm | 1100*830*1080mm | 1850*1080*1280mm | 2020*1200*1380mm |

Weight | 170kg | 350kg | 800kg | 1100kg |

Application

Multi-purpose machine

Meat and vegetable bowl chopper machine mainly used for all kinds of meat roots, stems, leafy vegetables (carrots, potatoes,tomatoes, celery, cabbage, etc.) for cutting or grinding broken to make the dumplings and steamed&sausage ect

Q: Are you a trade company or a manufacturer?

A:we are a manufacturer welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock.or it is 35 days if the goods are not in

stock,we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes,we will supply all the parameters price,layout drawing factory design etc.

Q: What is your terms of payment?

A: 30% T/T in advance,70% balance before shipment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q: Do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Q: How about the machine warranty?

A: We provide 1 year warranty,Lifetime service.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock.or it is 35 days if the goods are not in

stock,we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes,we will supply all the parameters price,layout drawing factory design etc.

Q: What is your terms of payment?

A: 30% T/T in advance,70% balance before shipment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q: Do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Q: How about the machine warranty?

A: We provide 1 year warranty,Lifetime service.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices