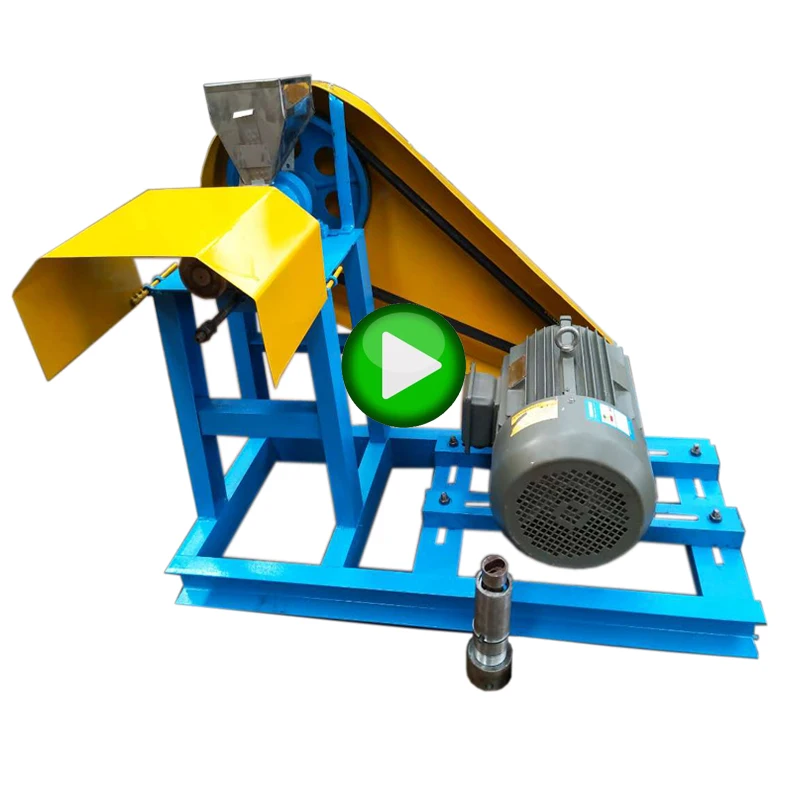

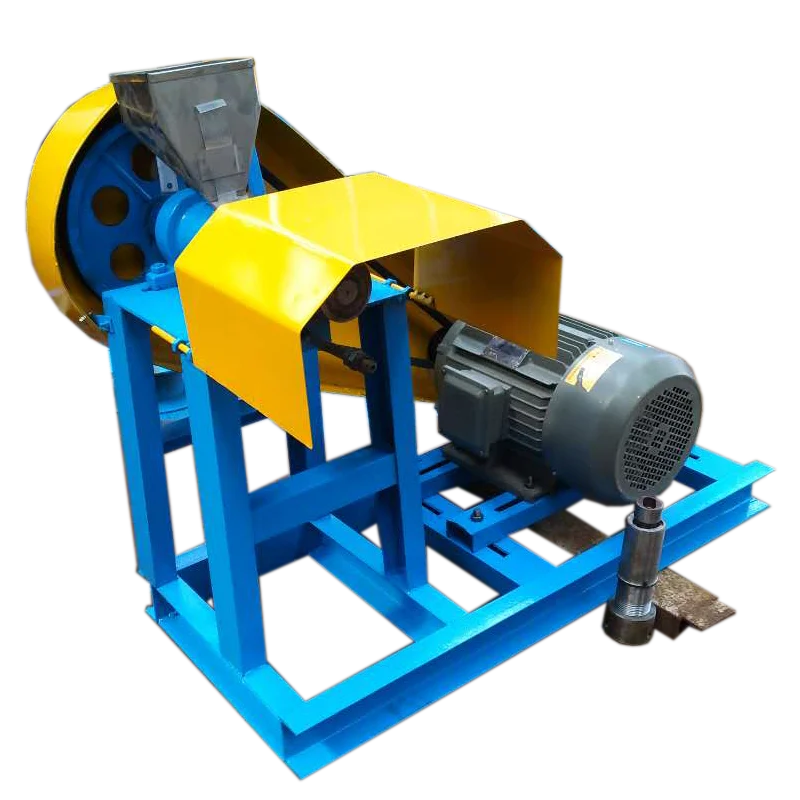

Large And Efficient Food Processing Equipment Corn Puff Extruder Millet Sorghum Snack Food Machine

- Category: >>>

- Supplier: Lerford Machine LLCLerford LLC

Share on (1601259123552):

Product Overview

Description

Corn puff extruder machine is also known as a puffing snack food machine or corn snack extruder. It is a mechanical device that is used to produce different types of puff snacks made from corn, rice, wheat, and other grains. The machine works by processing raw materials into desired shapes and sizes using the latest technology and high-quality materials.

Functional features of puffing snack food machine

1. High-quality production: This machine is designed to continuously produce high-quality puffed snacks to meet the needs of consumers.

2. Wide range of uses: This machine can produce puffed snacks of different shapes and sizes, including ring, ball, pillow, stick, etc.

3. Easy to operate: This machine is user-friendly, easy to operate, and saves labor costs.

4. Low maintenance: The machine adopts low maintenance cost design, saving money for the owner.

5. Automated production: The machine is equipped with an automatic control system, making the production of puffed snacks efficient and reliable.

6. Operational safety: The machine has safety features to protect the operator during the production process.

How corn snack extruder works

The corn snack extruder works by mixing the ingredients with water and passing them through an extrusion system. The extrusion system consists of a preconditioner and an extruder barrel, in which the raw materials are mixed and processed. The machine uses a high-pressure and high-temperature system to cook raw materials and convert them into puffed snacks. The raw materials are then passed through molds to obtain the desired shape and size of puff snacks.

Advantages of corn puff snacks extruder

1. High production efficiency: The corn puff snacks extruder can achieve continuous production and is fast, capable of producing a lot of food in one minute.

2. One machine for multiple purposes: The corn puff snacks extruder can produce various types of puffed foods according to needs.

3. Simple operation: The operation of corn puff snacks extruder is very simple. You only need to put the raw materials into the machine and turn on the machine.

4. Simple production process: The production process of corn puff snacks extruder is relatively simple, which can save processing plants a lot of time and labor.

Technical information

Model | WSPH-40 | WSP-50 | WSPH-80 | WSPH-190 |

Main material | Rice, corn, broomcorn, maize, beans etc | |||

Motor power | 4.5-5.5kw, 380&220V or 6-8HP

| 4-5.5kw, 380&220V, or 6-8HP (with 2pcs of V belts) | 5.5-11kw, 380v, or 6-8HP (dia 90-100mm)

| 15kw, 380v, or F175 6-8HP (with 2pcs of V belts, dia 90-100mm)

|

Output | 30-40kg/hour

| 40-50kg/h | 60-80kg/h | 100-120kg/h |

Rotated speed | 500-600rp/min | 500-600rp/min | 440-550r/min

| 440-550rp/min |

Weight | 150kg | 180kg | 200kg | 220kg |

Packing size | 1080*670*920mm

| 1180*770*920mm | 1280*770*1020mm

| 1380*870*1120mm

|

Machine instructions

1. Before operation, you need to check whether all parts of the machine are complete and perform maintenance.

2. Put the raw materials into the machine, make sure they are placed evenly and do not tilt or overdo it.

3. Turn on the machine's power switch and start the machine.

4. Adjust the amount of heating, squeezing and pressure as needed.

5. After food production is completed, turn off the machine's power switch, remove accessories, and clean the machine.

6. Pack up the machine and store it as required for next use.

Common problems and solutions during machine use

1. Uneven feed of raw materials: Adjust the arrangement of raw materials to make the arrangement of raw materials as uniform as possible.

2. The food produced is uneven: adjust the heating, extrusion and pressure of the machine to achieve a balanced state as much as possible.

3. Machine failure: If the machine fails, you need to stop using it immediately and find a professional to repair it.

What is the quality inspection process for our machines?

Our machine quality inspection process is very complete, covering various procedures such as raw material procurement, processing, assembly, inspection, and complete machine debugging. Our products are repeatedly inspected and tested before leaving the factory to ensure that each machine has excellent performance and quality.

What is the pre-sales and after-sales service of our factory?

We have comprehensive pre-sales and after-sales services to ensure that our customers are satisfied with our corn crisp puffer. Our pre-sales service includes providing customers with detailed information about the machine and its capabilities. In addition, we provide technical support to our customers.

Our after-sales service provides customers with the necessary support to ensure they are satisfied with their purchase. Our after-sales services include training operators, providing spare parts and providing technical support.

What are the advantages of our factory?

1. High-quality machines: Our machines are of high quality and are designed to meet customer needs.

2. Customizable machines: We offer customizable machines to meet the specific needs of our customers.

3. Comprehensive Service: We offer our customers comprehensive support before and after the sale.

4. Experienced team: Our team consists of experienced technicians and engineers who ensure that we produce high-quality machines.

5. Competitive pricing: We offer our machines at competitive prices while maintaining high quality.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices