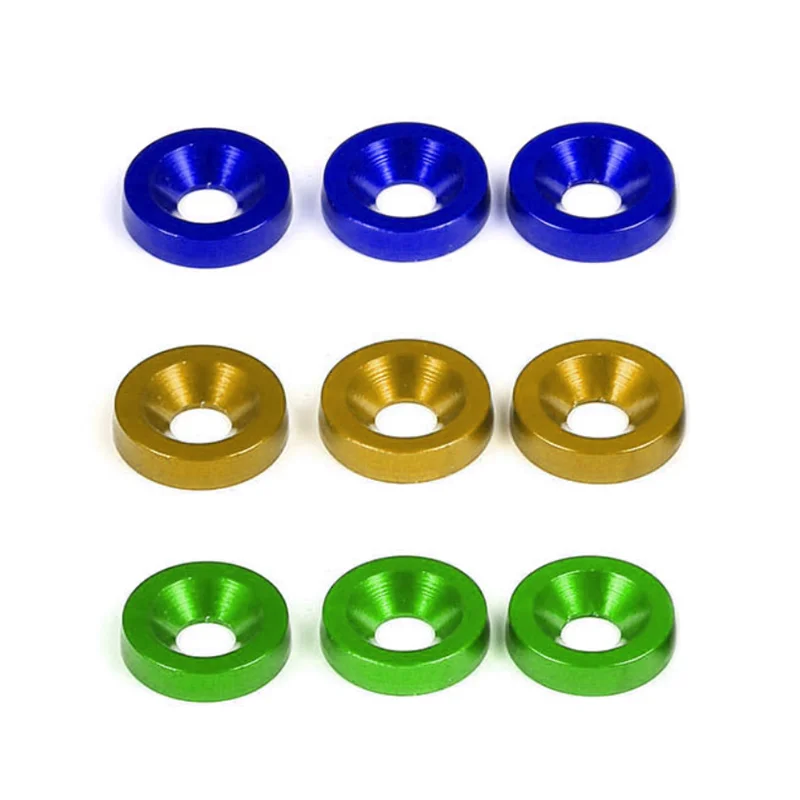

OEM Custom Colorfully Aluminum alloy Anodized Washer JDM M3M4M5M6M8 Fender Washer With Screw Kit

- Category: >>>

- Supplier: Chuanghe Fastener Co. Ltd.Chuanghe Ltd.

Share on (1601260336687):

Product Overview

Description

Product details

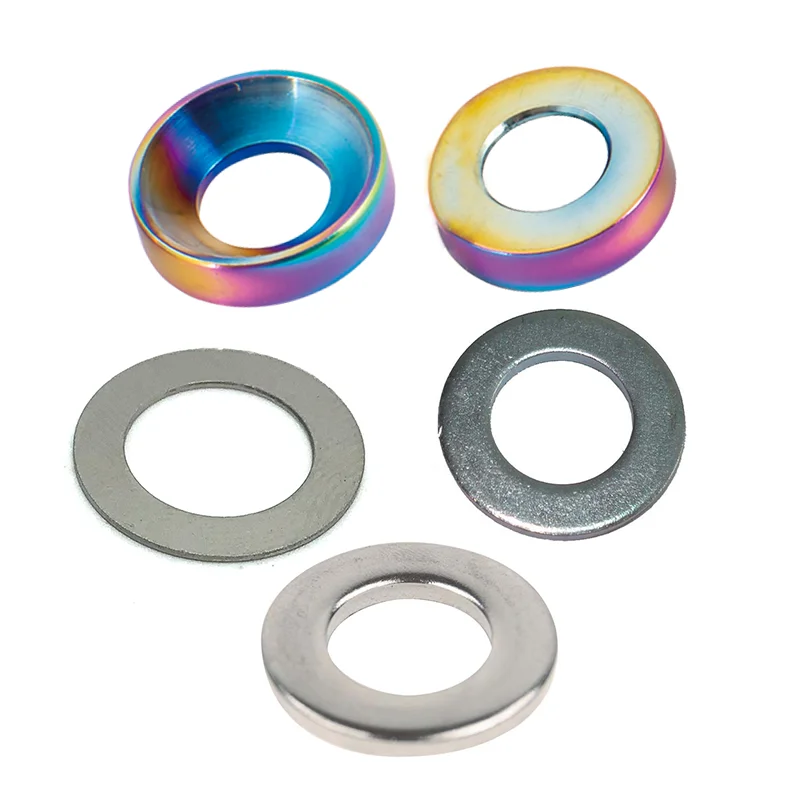

Product Name | Color Anodized Aluminum Stainless Steel Countersunk Bumper Fender Countersunk Cup Washer For Screw |

Material | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

Size | Customized Size Or Client's Drawings |

Tolerance | +/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Finish | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

Color | Red,Golden,Purple,Black,Silver,Blue,Green,etc. |

Drawing format | 3D/CAD/DWG//STEP/PDF |

Certification | IATF 16949 ISO14001, ISO9001,ROHS,etc |

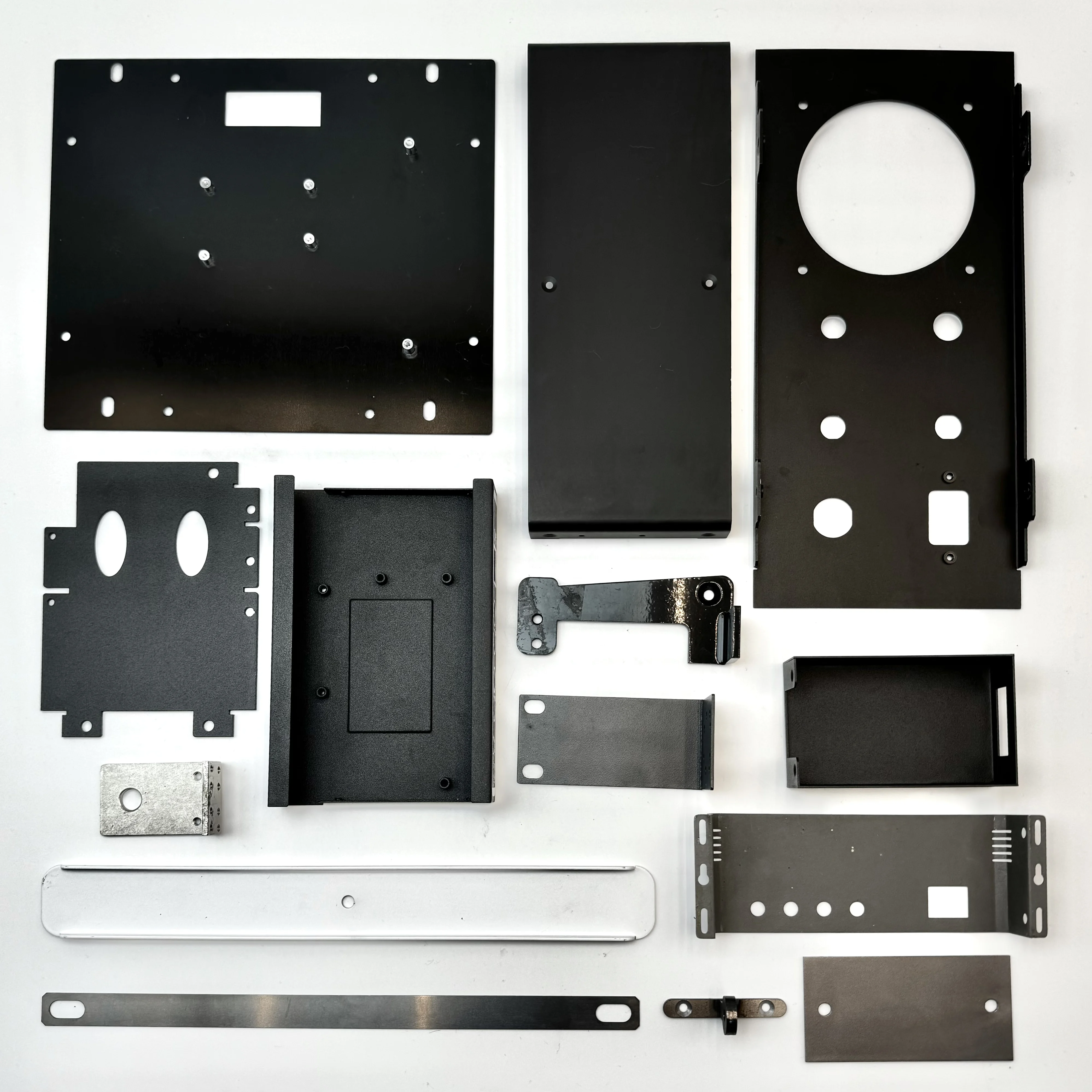

Types of Stamping | We offer single and multistage, progressive die, deep draw, fourslide, and other stamping methods to ensure the most effective method for manufacturing your products |

Process | Laser;Cutting;Bending;Stamping |

Service | Customize ODM OEM |

Application | Fender washer are commonly used in automotive,sheet metal,plumbing and electrical applications |

Advantages of Metal Stamping

A fender washer,though similar in shape to a standard washer,differs in that the outside diameter is traditionally much larger in proportion to the center ole. With this design,a fender washer can be placed under the head of a bolt or nut to help distribute forces applied when tightening. Its oversized outside diameter also provides more bearing surface for the load of the fastener-distributing the load further on soft or thin materials

A fender washer,though similar in shape to a standard washer,differs in that the outside diameter is traditionally much larger in proportion to the center ole. With this design,a fender washer can be placed under the head of a bolt or nut to help distribute forces applied when tightening. Its oversized outside diameter also provides more bearing surface for the load of the fastener-distributing the load further on soft or thin materials

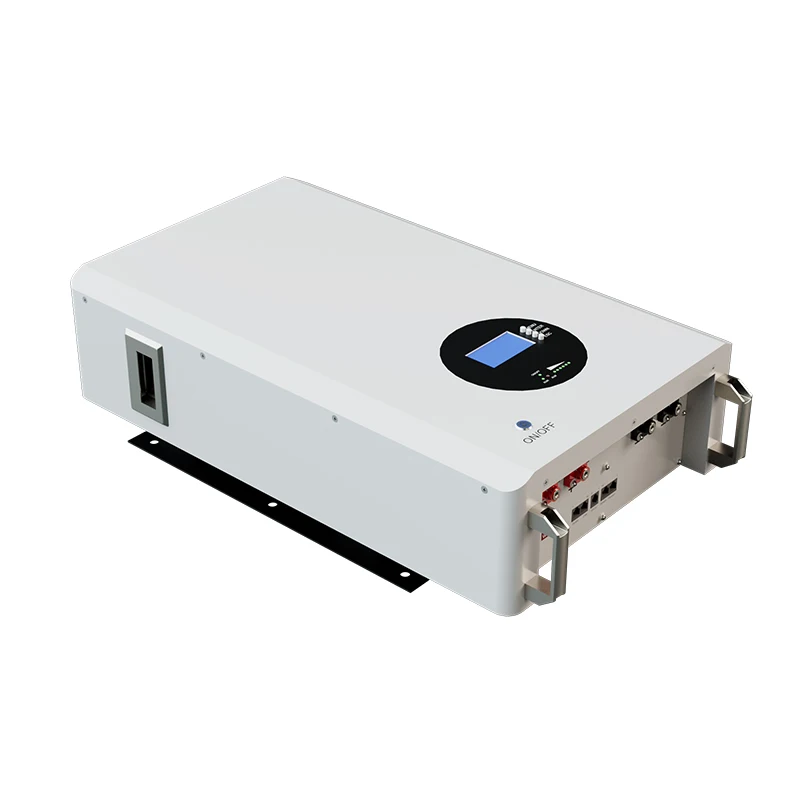

Related products

1, Main Materials | ||||||||

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. | |||||||

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||||||

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||||||

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||||||

Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||||||

Copper | C11000,C12000,C12000, C36000 etc. | |||||||

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. | |||||||

2, Surface Treatment | ||||||||

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving | |||||||

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated | |||||||

Aluminum | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing | |||||||

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving | |||||||

3, Quality Control | ||||||||

1.Checking the raw material after they reach our factory------- Incoming quality control ( IQC) | ||||||||

2. Checking the details before the production line operated | ||||||||

3. Have full inspection and routing inspection during mass production---In process quality control(IPQC) | ||||||||

4. Checking the goods after they are finished---- Final quality control(FQC) | ||||||||

5. Checking the goods after they are finished-----Outgoing quality control(OQC) | ||||||||

Company Introduction

Exhibition&Visitors

1) Design assistance and full engineering support . | ||||||||

2) Professional at OEM CNC parts . | ||||||||

3) Complete production lines for custom turning, milling, CNC machining sheet metal fabrication, stamping, bending, argon welding and surface treatment. | ||||||||

4) Advanced machine tools, CAD/CAM programming software. | ||||||||

5) Prototype machining capabilities. | ||||||||

6) Strict quality control standards with a highly qualified inspection department . | ||||||||

7) Continually upgrading and advancing our equipment to remain competitive . | ||||||||

Certifications

Packaging&Shipping

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: Can I visit your factory?

A2: Yes! Warmly welcome to visit our factory. It would be Great if you can inform us in advance.

Q3:The quality of your products?

A3:The company has advanced production and testing equipment .Every products will be 100% inspected by our qc department before

shipment.

Q4:How about your price?

A4:High quality products with reasonable price. Please give me a inquire, I will quoted you a price for you refer at once.

Q5:Could you provide free samples?

A5:We can provide free samples for standard fastener, But the clients will pay the Express charges.

Q6: What’s your Delivery Time?

A:Standard parts: 7-15days,Non-standard parts: 15-25days.We will make the delivery as soon as possible with the guarantee quality.

Q7: How should I order and make payment?

A7:By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance

to be paid before shipment.

A1: We are factory.

Q2: Can I visit your factory?

A2: Yes! Warmly welcome to visit our factory. It would be Great if you can inform us in advance.

Q3:The quality of your products?

A3:The company has advanced production and testing equipment .Every products will be 100% inspected by our qc department before

shipment.

Q4:How about your price?

A4:High quality products with reasonable price. Please give me a inquire, I will quoted you a price for you refer at once.

Q5:Could you provide free samples?

A5:We can provide free samples for standard fastener, But the clients will pay the Express charges.

Q6: What’s your Delivery Time?

A:Standard parts: 7-15days,Non-standard parts: 15-25days.We will make the delivery as soon as possible with the guarantee quality.

Q7: How should I order and make payment?

A7:By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance

to be paid before shipment.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices