Metal ore Dust powder Iron Tin Phosphate Powder briquetting machine

- Category: >>>

- Supplier: Henan Hengtailong Machinery Co. Ltd.

Share on (1601260949175):

Product Overview

Description

Product Description

china factory hot sale diesel engine coal charcoal power briquette making press machine with good price

It can press the pulverized coal,iron powder,mineral powder,aluminum powder,coke powder and other hundreds of materials,widely used in resistant materials,energy,heating and other industries.

Model | Gear reducer | Motor(KW) | Capacity(T/H) | Dimension(m) |

290 | YQ350 | 5.5 | 1-2 | 1.5*1.2*1.6 |

360-1 | YQ350 | 7.5 | 2-3 | 1.7*1.2*1.6 |

360 | YQ400 | 11 | 2-3 | 1.7*1.6*1.8 |

450 | YQ500 | 22 | 4-5 | 1.8*1.9*2.2 |

550 | YQ650 | 37 | 5-7 | 2.4*2.2*2.3 |

650 | YQ750 | 45 | 8-10 | 2.6*2.2*2.7 |

850 | YQ1000 | 75 | 15-20 | 2.6*2.4*3.2 |

1000 | YQ1200 | 110 | 25-30 | 2.9*2.8*3.5 |

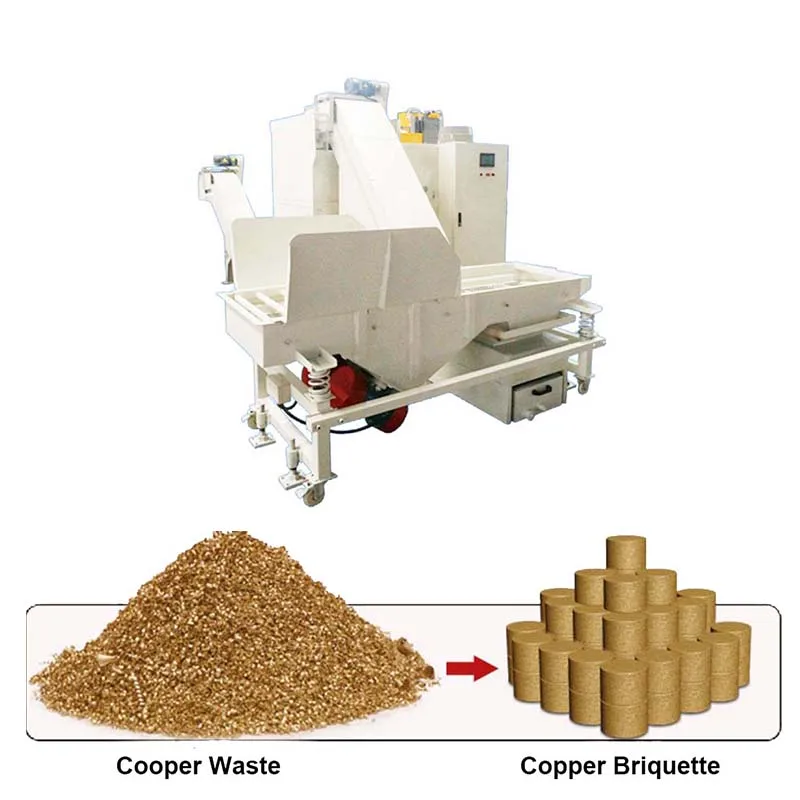

Raw Materials & Finished Products

Raw Materials:

The charcoal briquette machine, charcoal making machine, sawdust coal briquette forming equipment and rice husk coal briquette forming equipment can be used to press various powders, waste residues such as pulverized coal, iron powder, coking coal, aluminum

powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, activated carbon and coke powder.

Rollers/Moulds and final products:

>> 1.The finished products usually 20-60mm.

>> 2.The final products are smokeless, non-toxic, none peculiar and environmental protection.

>> 3.The shape can be Square, ball egg-shaped, round, oval, and column, strip-type, elliptic type,pillow type and other special shapes by customizing the matching molds.

Briquetting presss machine are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries..

>> 3.The shape can be Square, ball egg-shaped, round, oval, and column, strip-type, elliptic type,pillow type and other special shapes by customizing the matching molds.

Briquetting presss machine are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries..

Final Products:

With this innovative briquette maker, you are enabled to briquetting or pressing any biomass material including wood chips,sawdust, ag waste, straw, stalks etc into round shaped sawdust briquette machine of 70mm diameter or pellets of 8mm, 10mm, 22mm, 30mm.

With this innovative briquette maker, you are enabled to briquetting or pressing any biomass material including wood chips,sawdust, ag waste, straw, stalks etc into round shaped sawdust briquette machine of 70mm diameter or pellets of 8mm, 10mm, 22mm, 30mm.

What you need to do is only simply changing the molding parts to shift function between briquetting and pelletizing.

Working Principle

This series of small briquette shaping machine will pass the power on to the two pressure roller through the reducer.

The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak.

Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

About Hengtailong

Gongyi Hengchang Metallurgical Building Materials Equipment Factory is located in Zhengzhou, Henan Province, China, specializing in the research and development, manufacturing, and sales services of mining equipment.

We can provide a complete set of equipment including crushing, screening, mineral separation, etc.

The product has been exported to markets in Southeast Asia, the Middle East, Africa, and the Americas. Agents have also been developed in Egypt, Pakistan, Vietnam, and other countries. We provide high-quality products, the best solutions, professional technical support, and excellent after-sales service.

The product has been exported to markets in Southeast Asia, the Middle East, Africa, and the Americas. Agents have also been developed in Egypt, Pakistan, Vietnam, and other countries. We provide high-quality products, the best solutions, professional technical support, and excellent after-sales service.

Customer Visits/Evaluations/Our Services

Product Packaging

Packaging Details:

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packing. Wooden box or carton box packing.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 15 to 25working days.

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packing. Wooden box or carton box packing.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 15 to 25working days.

RFQ

Q:Why we believe in Gongyi Hengchang company?

A: 1.More than 28 years’ experience.

2.Hengchang is the leading professional supplier of solution, equipment’s and service for crushing and grinding industry.

3.Products achieved ISO9001:2000 quality management certificate and EU CE certificate.

Q:Deliver time ?

A:The lead time is 10-20 days, Delivery time will vary depending on the type of the machine, shipping method selected and part availability.

Q:Payment terms ?

A:Accepted Payment Type: T/T, L/C, Western Union, Cash and so on. After sign

the contract, pay the 10%-30% deposit of total purchase price and pay the full payment before delivery.

Q:What will you do if the machine is broken down?

A:The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

Q:What should i do if I want to get a best quotation?

A:If you want a suitable type for you, please let us know your material and capacity.

2.Hengchang is the leading professional supplier of solution, equipment’s and service for crushing and grinding industry.

3.Products achieved ISO9001:2000 quality management certificate and EU CE certificate.

Q:Deliver time ?

A:The lead time is 10-20 days, Delivery time will vary depending on the type of the machine, shipping method selected and part availability.

Q:Payment terms ?

A:Accepted Payment Type: T/T, L/C, Western Union, Cash and so on. After sign

the contract, pay the 10%-30% deposit of total purchase price and pay the full payment before delivery.

Q:What will you do if the machine is broken down?

A:The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

Q:What should i do if I want to get a best quotation?

A:If you want a suitable type for you, please let us know your material and capacity.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices