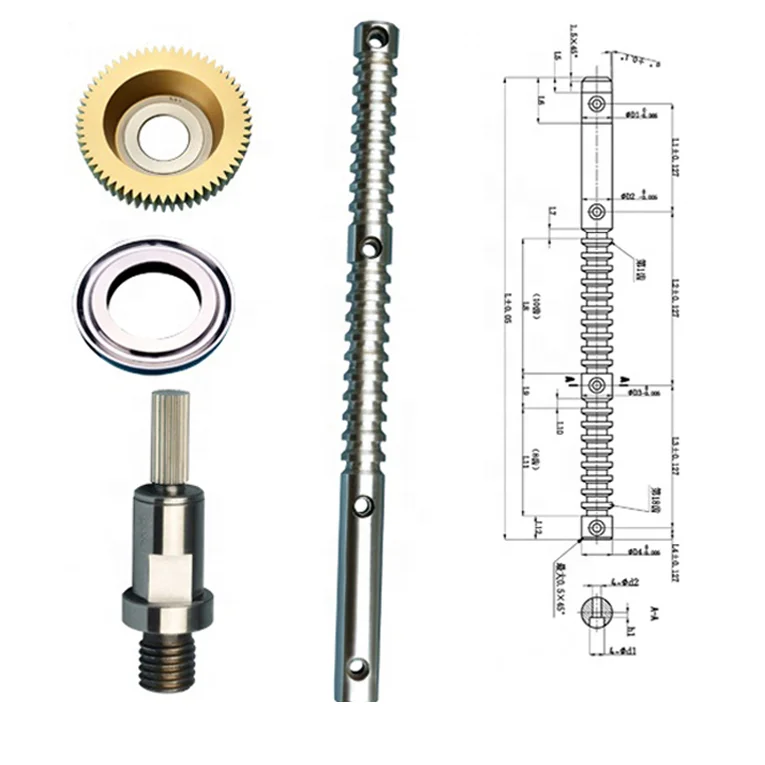

stainless steel broach Keyway Broaches Rectangular Spline Broach

- Category: >>>

- Supplier: Henan Wogeng Machinery Equipment Co. Ltd.

Share on (1601264728498):

Product Overview

Description

Product Description

Specification

| Keyway broach | |||||

| Specification | Broach length | Total length | Width | Height | Calibration height |

| 8 | 18-30 | 780 | 12 | 18 | 22 |

| 8Standard | 18-30 | 805 | 12 | 16 | 20.5 |

| 8Chamfer | 18-30 | 860 | 12 | 18 | 22 |

| 8Chamfer | 18-30 | 855 | 12 | 16 | 20.5 |

| 8 | 30-50 | 960 | 12 | 18 | 22 |

| 8Standard | 30-50 | 960 | 12 | 18 | 22.25 |

| 8Chamfer | 30-50 | 1030 | 12 | 18 | 22 |

| 8 | 50-80 | 1150 | 12 | 18 | 22 |

| 8Chamfer | 50-80 | 1260 | 12 | 18 | 22 |

| 8 | 80-120 | 1260 | 12 | 18 | 22 |

| 8Chamfer | 80-120 | 1330 | 12 | 18 | 22 |

| 10 | 30-50 | 950 | 15 | 22 | 26.6 |

| 10Chamfer | 30-50 | 1050 | 15 | 22 | 26.6 |

| 10 | 50-80 | 1200 | 15 | 22 | 26.6 |

| 10Chamfer | 50-80 | 1300 | 15 | 22 | 26.6 |

| 10 | 80-120 | 1370 | 15 | 22 | 26.6 |

| 10Chamfer | 80-120 | 1450 | 15 | 22 | 26.6 |

| 12 | 30-50 | 950 | 12 | 28 | 32.8 |

| 12Chamfer | 30-50 | 1050 | 12 | 28 | 32.8 |

| 12 | 50-80 | 1280 | 12 | 28 | 32.8 |

| 12Chamfer | 50-80 | 1330 | 16 | 28 | 32.8 |

| 12 | 80-120 | 1380 | 12 | 28 | 32.8 |

| 12Chamfer | 80-120 | 1450 | 16 | 28 | 32.8 |

| 12 | 80-120 | 950 | 12 | 28 | 31 |

Advantages

Advantages of Keyway Broaching on CNC Lathes

Keyway broaching on CNC lathes offers several advantages over traditional broaching machines:

- Flexibility: Indexable inserts allow for a great flexibility with various tolerances (such as H7, JS9, P6, D10, C11) and profiles (square, hexagon, spline) at a relatively low cost.

- Precision and Repeatability: CNC lathes offer high levels of precision and repeatability, ensuring consistent and accurate keyway dimensions across multiple workpieces. This precision is essential for achieving the proper fit between the key and the keyway, which is critical for reliable torque transmission.

- Reduced Setup Time: Cutting keyways on a CNC lathe eliminates the need for dedicated broaching machines and reduces setup time.

- Reduced Logistics Efforts: An alternative approach is outsourcing the work to a contract manufacturer. However, this creates additional logistical efforts such as batching, labelling and shipping the parts.

- Cost-Effectiveness (Machine): As CNC lathes can perform multiple operations, using a single machine can save on costs associated with acquiring and maintaining dedicated broaching machines.

- Cost-Effectiveness (Tooling): Traditional multi-tooth broaches that are used on broaching machines are relatively expensive. This makes buying and keeping multiple sizes and tolerances costly.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices