High quality China mold factory for plastic injection parts cheap price one stop service 20 years experience for mold making

- Category: >>>

- Supplier: Dongguan Tong Ying Sheng Plastic Electronics Production Co. Ltd.

Share on (1601265279750):

Product Overview

Description

Products Description

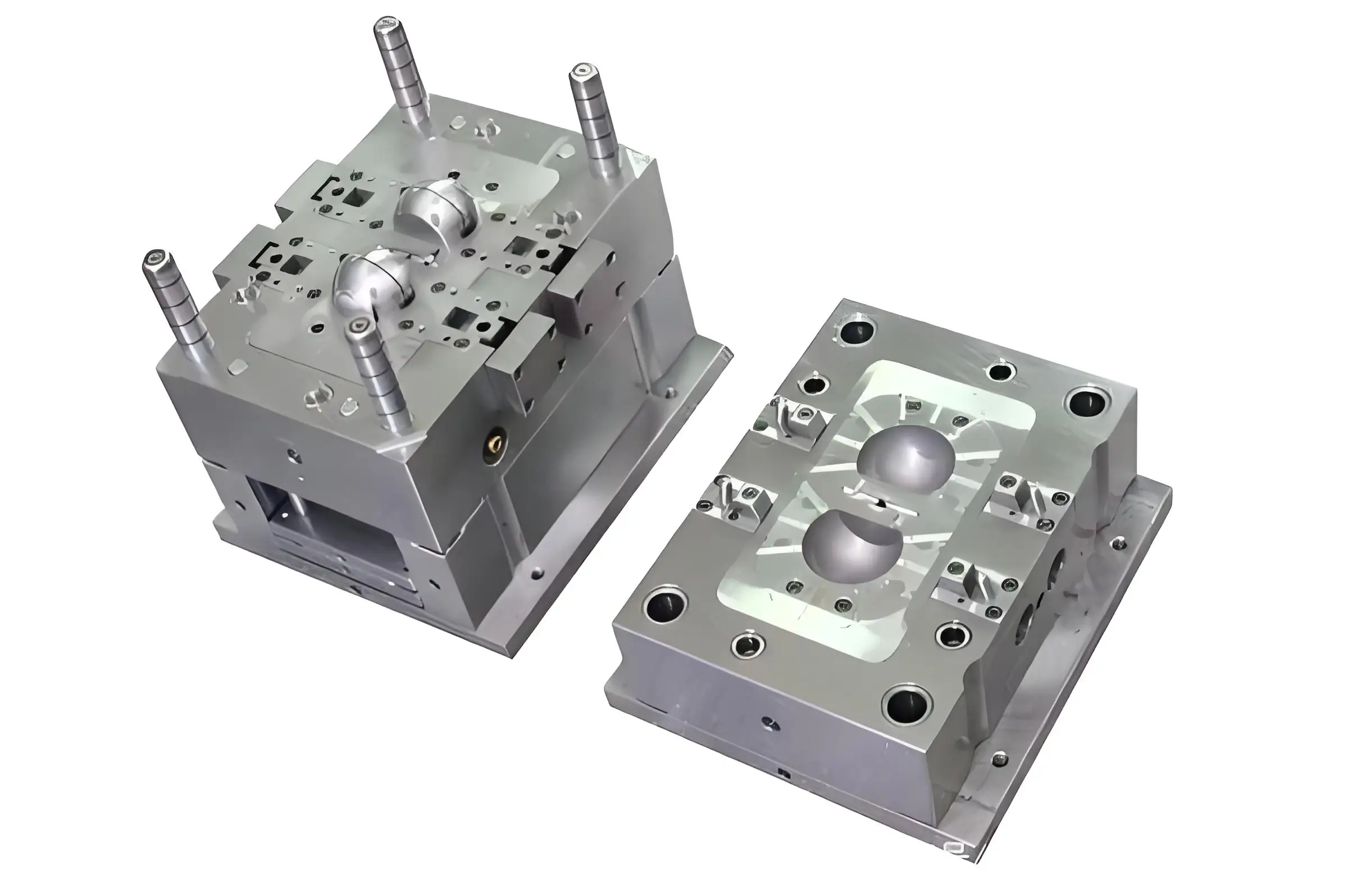

Product Description | professional high precision plastic injection parts |

Application field | Various plastic injection molded parts for various industrial and automotive applications |

Equipments | CNC、EDM、Cutting Off Machine、Plastic Machinery etc. |

Experience | 20 years experience in plastic injection mold making and and injection molding. |

Certification | ISO9001:2024 and relate whole set professional test report |

Quality | RoSH and SGS standard |

Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

Mould material | P20/ 718H/ S136H/ S136 hardened/ NAK80 |

Injection machine | 50T, 60T, 120T, 150T, 160T, 250T,280T,350T |

Mould Base | SD/LKM Standard/HASCO Standard Self-made |

Mould life | over 500k shots |

Surface Treatment | Matte, Common polishing, Mirror polishing, Texture, etc |

plastic parts treatment | silk screen printing,spray printing,pad printing,water transfer printing,heat transfer printing,uv printing ,electroplating etc. |

Size | According to your 2D, 3D Drawing. |

Tolerance | ± 0.01mm,some high precision mould for connector can be ± 0.003mm |

GateType | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate |

Free sample | available |

Advantage | One-stop service from design to final parts production and Flexible delivery time |

Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

Need to provide | 2D, 3D, samples, or the size of the multi-angle pictures |

Company Profile

DongGuan TYS Plastic Electronics Production

Co.,Ltd was founded in year 2018. We have been focus on plastic injection mold making and plastic injection production service

ever since.We now have nearly 20,000 square meter factory floor and over 50 skillful employees .

With so many years experience in product design, mold making,manufacturing, secondary processing, and final assembly, etc., TYS has developed into a one-stop service center.

Co.,Ltd was founded in year 2018. We have been focus on plastic injection mold making and plastic injection production service

ever since.We now have nearly 20,000 square meter factory floor and over 50 skillful employees .

With so many years experience in product design, mold making,manufacturing, secondary processing, and final assembly, etc., TYS has developed into a one-stop service center.

How to work with us

Mold and Plastic Description

Mould Making Details | ||

Name | Plastic Injecition Mold | |

Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed | |

Mould base | LKM, HASCO, DME or upon customer's requirement | |

Type of plastic mold | 3-plate mold,2-plate mold | |

Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc | |

Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve | |

Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc | |

Runner | Hot/cold type | |

Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES | |

Mould life | 300,000-1,000,000 shots | |

Lead time | 15-35days after deposit received | |

Specification | Follow the 3D final drawing | |

Packaging details | covering with film for anti rust and packed with wooden Case | |

Plastic Parts Production Details | ||

Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc | |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc | |

Packaging details | Carton box or wooden Case upon product weight and customer's requirements. | |

Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. | |

Typical Used For | Housings, containers, caps, fittings,including as below Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings | |

Shipping | By sea or by air as customer requirement | |

Mould or Plastic Export | ||

Mold Export | For customer who only want moulds by us,we Firstly assembling and clearing mold well, and then paint anti-rust fog or grease on mold, then cover with thin film and place it into a stable wooden case. | |

Plastic parts Export | Firstly,to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into cartons with thin sponge plates to prevent scratches.for the final products ,like a finished product,we can do gift box or other packing methods customer want us to pack for shipping | |

FAQ

1. Does your company make mould by yourself?

2. How many kinds of moulds can you make? Only make the moulds?

3.What's the software you will use to check the drawing? And what's format of drawing you cancheck?

4. Will you send me the free sample?

Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk.

5. How to pack the moulds and products?

For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on themould, finally pack

into non-fumigation wooden case And as to products, we will pack into standard export cartons or as per customers requres to pack.

6. I only have samples in hand, can you also make the product for me?

Yes, you can send us samples, we can help you make 3D models according to the samples and finally, we can help you develop theprojects with mass production.

7. My requirement is low volume at the beginning, can you also help me to custom my products?

Yes, we can start from smaller quantity as we are manufacturer.

Yes, we are manufacturer with about two decades of molding experience.

2. How many kinds of moulds can you make? Only make the moulds?

We can make many kinds of moulds, such as plastic injection moulds, blowing moulds, stampingmould, die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

3.What's the software you will use to check the drawing? And what's format of drawing you cancheck?

Our designers and engineersall use AUTO CAD and Soliworks software to check 2D and 3d drawing We can check the drawings with PDF, Al, DWG(CAD ) and STP(3D)or IGS(3D)formats.

4. Will you send me the free sample?

Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk.

5. How to pack the moulds and products?

For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on themould, finally pack

into non-fumigation wooden case And as to products, we will pack into standard export cartons or as per customers requres to pack.

6. I only have samples in hand, can you also make the product for me?

Yes, you can send us samples, we can help you make 3D models according to the samples and finally, we can help you develop theprojects with mass production.

7. My requirement is low volume at the beginning, can you also help me to custom my products?

Yes, we can start from smaller quantity as we are manufacturer.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices