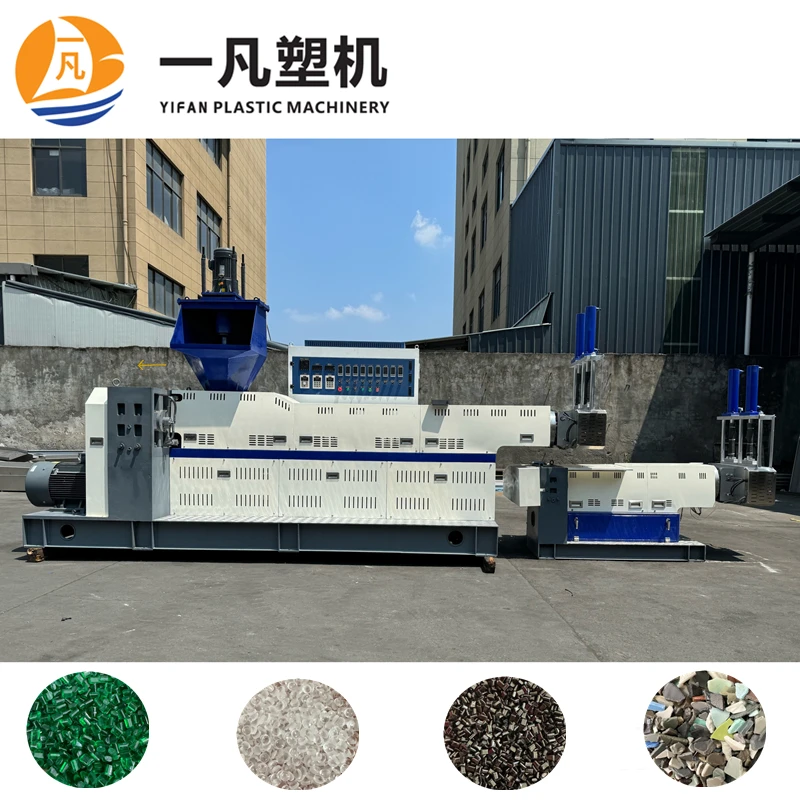

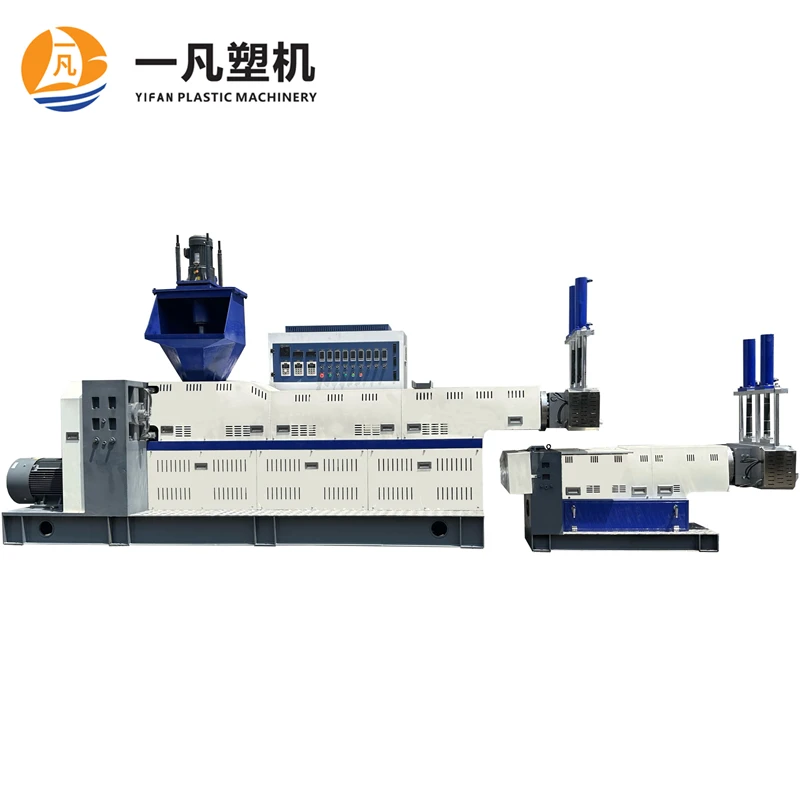

New Wood Plastic Pellet Granulator Machine Recycling Waste Manufacturing Plants

- Category: >>>

- Supplier: Ningbo Chaoyifan Plastic Machinery Co. Ltd.

Share on (1601266752353):

Product Overview

Description

The thin Film Plastics Granulator mainly used for HDPE, LDPE and PP plastic film to granulate after washing. Also for nylon waste silk, stocking toe, fabric, woven bag and network material to granulate.

Features:

1:Forced feeding hopper is used to ensure materials are cut evenly, less labor and high output.

2: The feeding throat of the main engine and the plasticizing segment are heated with electromagnetic heating. Dry plastic material and wet plastic material can be used to granulate.

3: Exclusively developed and designed. We have the independent research and development archives. The complete machine and parts are equipped reasonably. Three live lines and one zero line are used to heat.

4. The screw is designed for features of materials with high output. The material processed is glossy and plump-eared. The complete machine configuration increases to extend the service life of the equipment.

5: The granulator is characterized by high output and low energy consumption. With large torque reduction gearbox and electromotor, the screw is used without dead angle and jamming, which effectively increases the capacity and plasticizing effect. With single exhaust and dual exhaust structure, it can fully exhaust for dry material, wet material and washing material to make the granules solid and glossy.

6: The high-quality electrical engineering and device driver make the equipment more safe and reliable.

According to the customer's request for production, for the film, woven bag water granulation, the following general machine configuration parameters.

• For the loose cargo we will packing by wooden box.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: We have subsidiaries overseas to provide sales and after-sales services, including Taiwan, Japan, Thailand, Malaysia, Philippines, Indonesia. we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours online service to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We supply lifetime after sales service.

• We always update the new technology to every customer.

In order to match your requirement and provide you a proper quotation, please advise:

• What material do you want to recycling? ABS? PP? PE? PC? PBT? or other material?

• What capacity(kg/h) do you want?

• What is the final size(mm) of flakes you want?

• Other special requirements about the polyester fiber pelletizing machine you needt.

Q1:Do you support overseas after-sales service?

A: Yes, We have subsidiaries overseas to provide sales and after-sales services, including Taiwan, Japan, Thailand, Malaysia, Philippines, Indonesia.

Q2:how long is the warranty?

A:Within 1 year from date of the factory, if parts failure or damage

(because of the quality problem ,except wearing parts)

Q3:Do you provide technical support?

A:We provide lifelong technical support and offer on-site installation services overseas. Help each customer solve problems is our original intention.

Q4:The factors of plastic granulator line price?

1. Voltage and frequency in your country

2. The raw materials you are going to deal with, ABS PP PE PVC PET?

3. The output per day

4. The cleanliness of the raw materials, whether it needs to be cleaned (it is best to provide raw material pictures)

Q5:What is your payment term ?

A: 30% T/T in advance ,70% balance before shipment or Negotiable

If you have another question, please feel free to contact us.

We Recommend

Plastic Pellet Granulator/Pellet Cutting Machine for PP PE

Hard LDD SJP Extrusion plastic pelletizing machine

New Arrivals

New products from manufacturers at wholesale prices