Factory sales flexible honing brush, engine cylinder tube brush for cleaning and polishing

- Category: >>>

- Supplier: Shanghai Huixi Trading Co. Ltd.

Share on (1601268778172):

Product Overview

Description

Product Description

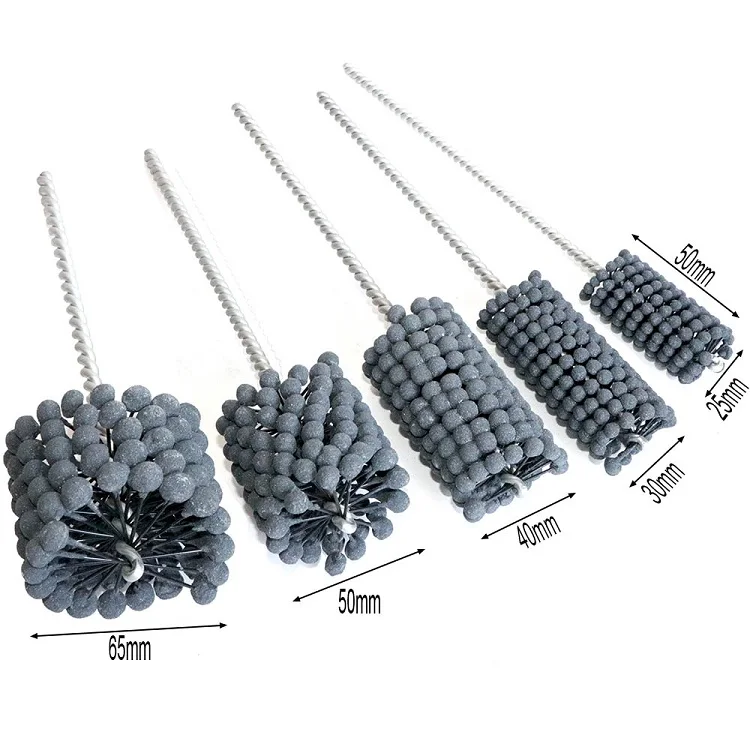

Factory sales flexible honing brush, engine cylinder tube brush for cleaning and polishing

Brush Material | Silicon Carbide,customized |

Other Materials | aluminum oxide, boron carbide, diamond, ceramic |

brush size | Diameter:65mm other:4~203MM,customized working part length:35mm, other:25~600mm,customized |

grit size | 240#, other:#60 #80 #120 #240 #320 #400 #600 #800 |

Function | Industrial cleaning, polishing, deburring, descaling |

Warranty | 1years |

Customized support | OEM/ODM |

Sample | Available |

Delivery | 10~12days |

Package | OPP Bag and Corrugated Carton |

Shipping | DHL/FedEx/UPA/ocean/train/truck |

Payment method | TT/PayPal/western union/credit card |

Trade terms | FOB/CIF/CFR/EXW/DDU |

Certificate | ISO9001, SGS, ROHS, REACH |

MOQ | 10 piece |

Place of Origin&Brand | China-AnHui,HX |

Product Advantages

1. Professional deburring: The ball brush is designed to remove the internal burrs of cylindrical parts and provide fine surface treatment. It is suitable for hydraulic, cylinder, engine parts and other industries.

2. Significant surface treatment effect: The metal surface effect after treatment is unmatched by other tools, and it is widely used in mechanical processing, brake hub and other industries.

3. Self-centering and self-adjusting function: The ball brush can control the center and self-adjust during the hole processing to offset the wear.

4. A variety of brush wire materials are available: Optional brush wires include silicon carbide, aluminum oxide, ceramics, diamonds, etc. to meet different processing needs.

5. Customized service: It can be customized according to customer needs to meet the specific needs of specific applications.

2. Significant surface treatment effect: The metal surface effect after treatment is unmatched by other tools, and it is widely used in mechanical processing, brake hub and other industries.

3. Self-centering and self-adjusting function: The ball brush can control the center and self-adjust during the hole processing to offset the wear.

4. A variety of brush wire materials are available: Optional brush wires include silicon carbide, aluminum oxide, ceramics, diamonds, etc. to meet different processing needs.

5. Customized service: It can be customized according to customer needs to meet the specific needs of specific applications.

Application

1. Hydraulic, cylinder, engine parts: Used for grinding these parts to improve the finish and quality of metal surfaces.

2. Mechanical processing: Used for grinding, deburring, rust removal, and polishing of the inner holes of mechanical parts to improve processing efficiency and product quality.

3. Automobile and shipbuilding: In the field of automobile and shipbuilding, it is used to grind and polish parts to ensure the accuracy and surface quality of parts.

4. Hardware products and industrial molds: used for grinding and polishing hardware products, as well as cleaning and maintenance of molds.

5. Pipe cleaning: suitable for grinding and cleaning the inner wall of the pipeline to remove impurities and burrs on the inner wall.

2. Mechanical processing: Used for grinding, deburring, rust removal, and polishing of the inner holes of mechanical parts to improve processing efficiency and product quality.

3. Automobile and shipbuilding: In the field of automobile and shipbuilding, it is used to grind and polish parts to ensure the accuracy and surface quality of parts.

4. Hardware products and industrial molds: used for grinding and polishing hardware products, as well as cleaning and maintenance of molds.

5. Pipe cleaning: suitable for grinding and cleaning the inner wall of the pipeline to remove impurities and burrs on the inner wall.

Excellent service

Strict quality control

1. Production:

During the production process, we select proven materials and use advanced factory equipment and processes to ensure the consistency and durability of the products. We focus on the quality of materials to ensure the performance of the products during use.

2. Factory quality inspection:

Before leaving the factory, the products will undergo a series of quality inspections, including tests on key indicators such as size and durability, to ensure that the products meet the established quality standards.

During the production process, we select proven materials and use advanced factory equipment and processes to ensure the consistency and durability of the products. We focus on the quality of materials to ensure the performance of the products during use.

2. Factory quality inspection:

Before leaving the factory, the products will undergo a series of quality inspections, including tests on key indicators such as size and durability, to ensure that the products meet the established quality standards.

3. Packaging: During the packaging stage, we will check the products again to ensure that they are intact, and then use suitable packaging materials to package them to protect the safety of the products during transportation and provide necessary product information.

4.shipping: DHL/UPS/FedEx/TNT door to door, ship by sea CIF/CFR/DAP/DDP/EXW, railway and van delivery door to door.

Fast communication and processing

We maintain close communication with our customers and respond quickly to their needs.

Through these processes, we are committed to providing customers with reliable quality products and properly handled every step from production to the hands of customers.

We are sincere manufacturer, supplier, factory

Product drawings

The price listed on the website is only for reference. The following are our standard sizes for your reference. If you don't know how to choose the size or what information to provide,Please contact our sales for an accurate quote based on your required brush dimensions as in following drawing:

Certifications

Company Profile

Our company is a specialized manufacturer of industrial brushes for sealing, cleaning, polishing and deburring, and has been serving a wide range of industries for many years. Our Anhui manufacturing base is located in Lingang, Shanghai, which is conveniently located, and was established as early as 2004. With our extensive experience in producing and exporting custom brushes worldwide, we have a deep understanding of brush manufacturing and are fully capable of meeting our customers' specific customization needs.

Our key advantages include:

1. More than 16 years of expertise in providing tailor-made brush solutions to customers around the world.

2. An experienced and professional team providing perfect OEM and ODM services.

3. Committed to providing high-quality products at competitive prices.

Our goal is to be able to provide customized brush solutions that meet our customers' unique needs, thanks to our many years of industry experience and our dedication to quality and service.

Our key advantages include:

1. More than 16 years of expertise in providing tailor-made brush solutions to customers around the world.

2. An experienced and professional team providing perfect OEM and ODM services.

3. Committed to providing high-quality products at competitive prices.

Our goal is to be able to provide customized brush solutions that meet our customers' unique needs, thanks to our many years of industry experience and our dedication to quality and service.

Production Process

Our main products include strip brushes, roller brushes, spiral brushes, tube brushes, lath brushes, scratch brushes, drill

brushes, wheel brushes, honing brushes, disc brushes, end brushes, panel brushes, etc. We can supply a variety of brushes for different applications and meet customers' special requirements on their brush products.

brushes, wheel brushes, honing brushes, disc brushes, end brushes, panel brushes, etc. We can supply a variety of brushes for different applications and meet customers' special requirements on their brush products.

Similar products

We can also make the following types of products or customize them according to your requirements. If you are interested, please feel free to contact us.

WE HAVE SPECIALIZED IN BRUSHES FOR MANY YEARS / WELCOME TO VISIT US AND THE FACTORY / BRUSH SAMPLE CAN BE PROVIDED / COMPETITIVE PRICE IS NEGOTIABLE / PROMPT DELIVERY PROMISED

We Recommend

MeiKeLa Fiber house paint paint roller brush

US $0.45-$0.75

Boars hair rock climbing bouldering brush

US $1.60-$1.90

New Arrivals

New products from manufacturers at wholesale prices